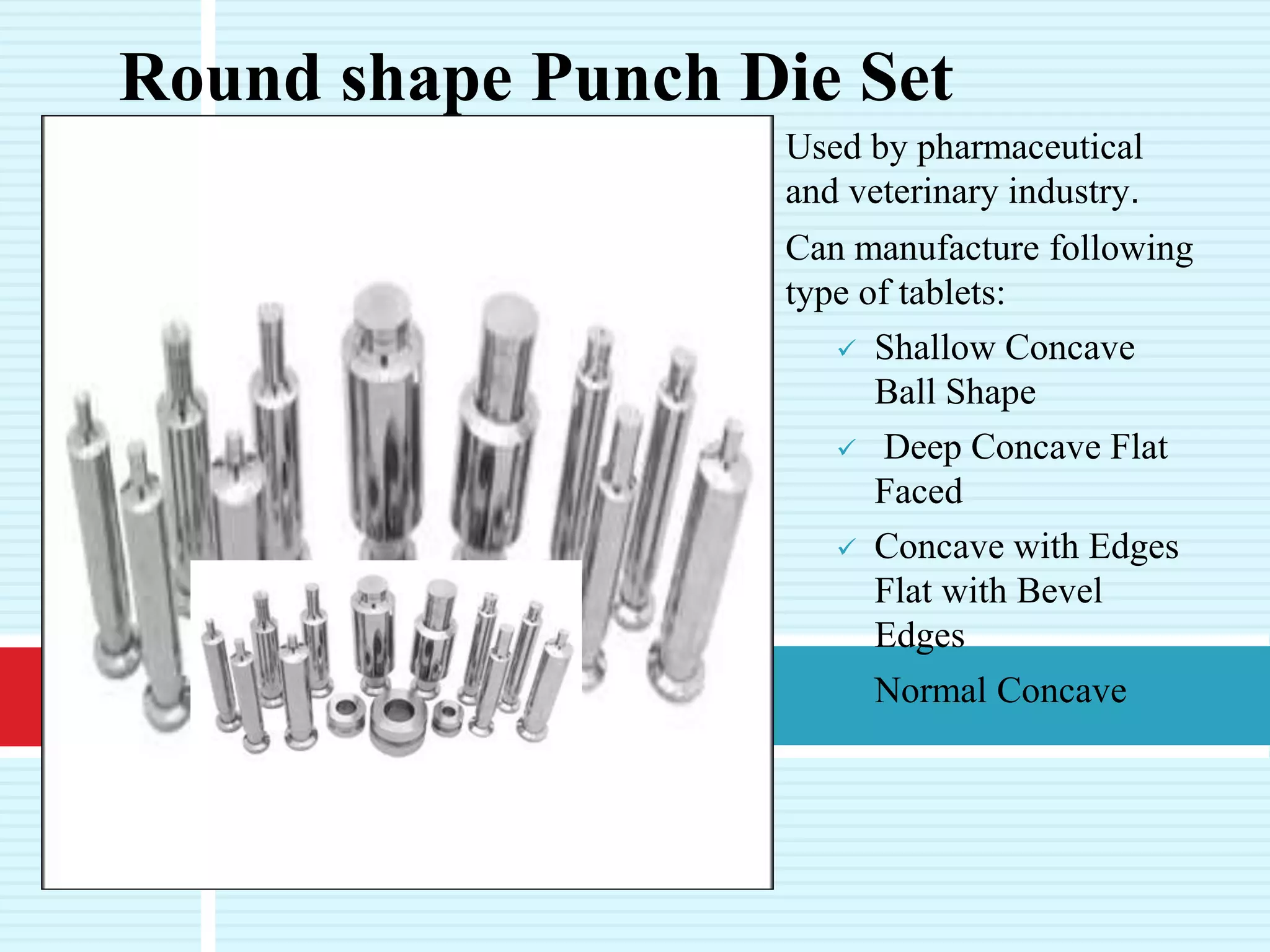

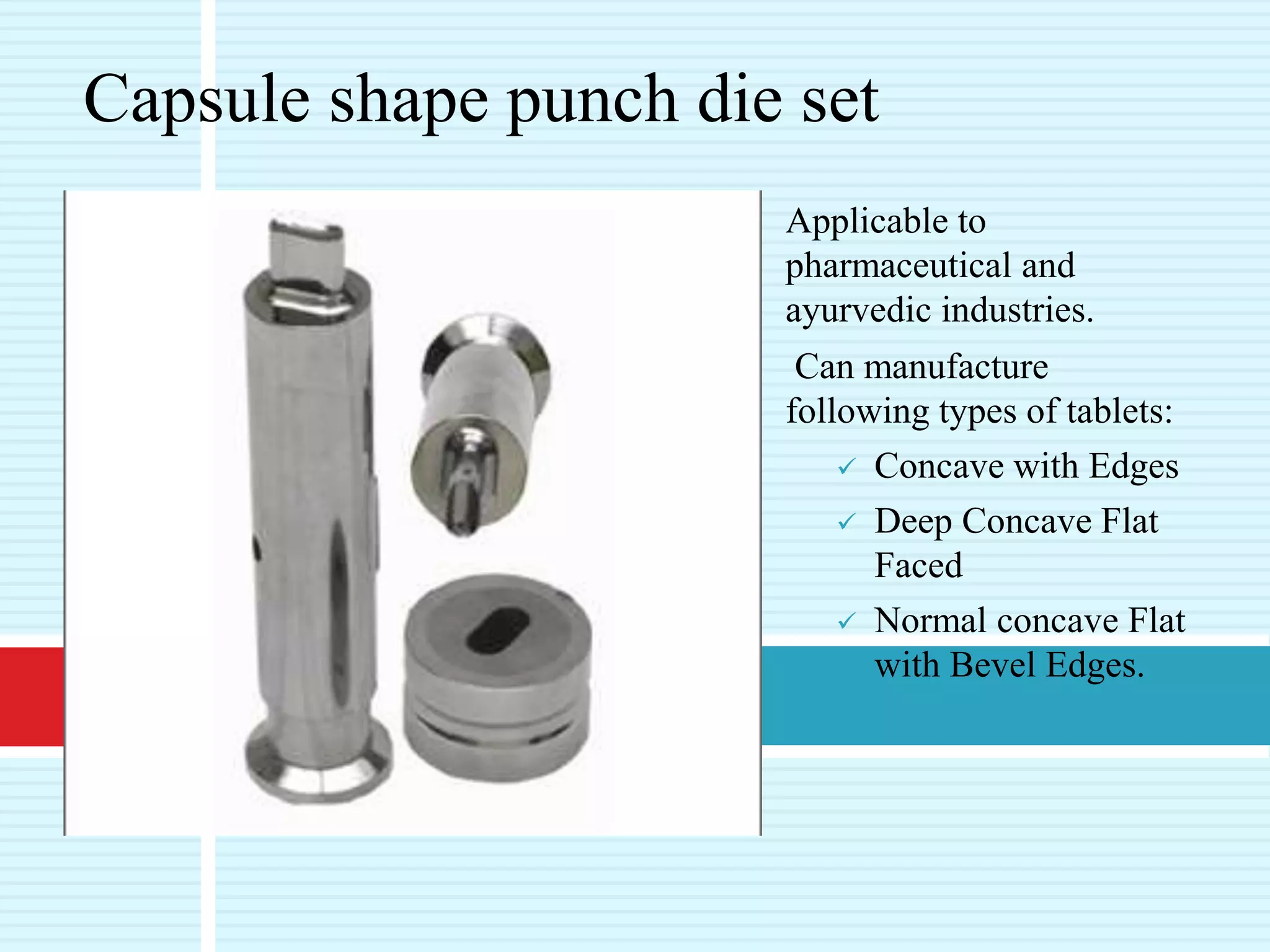

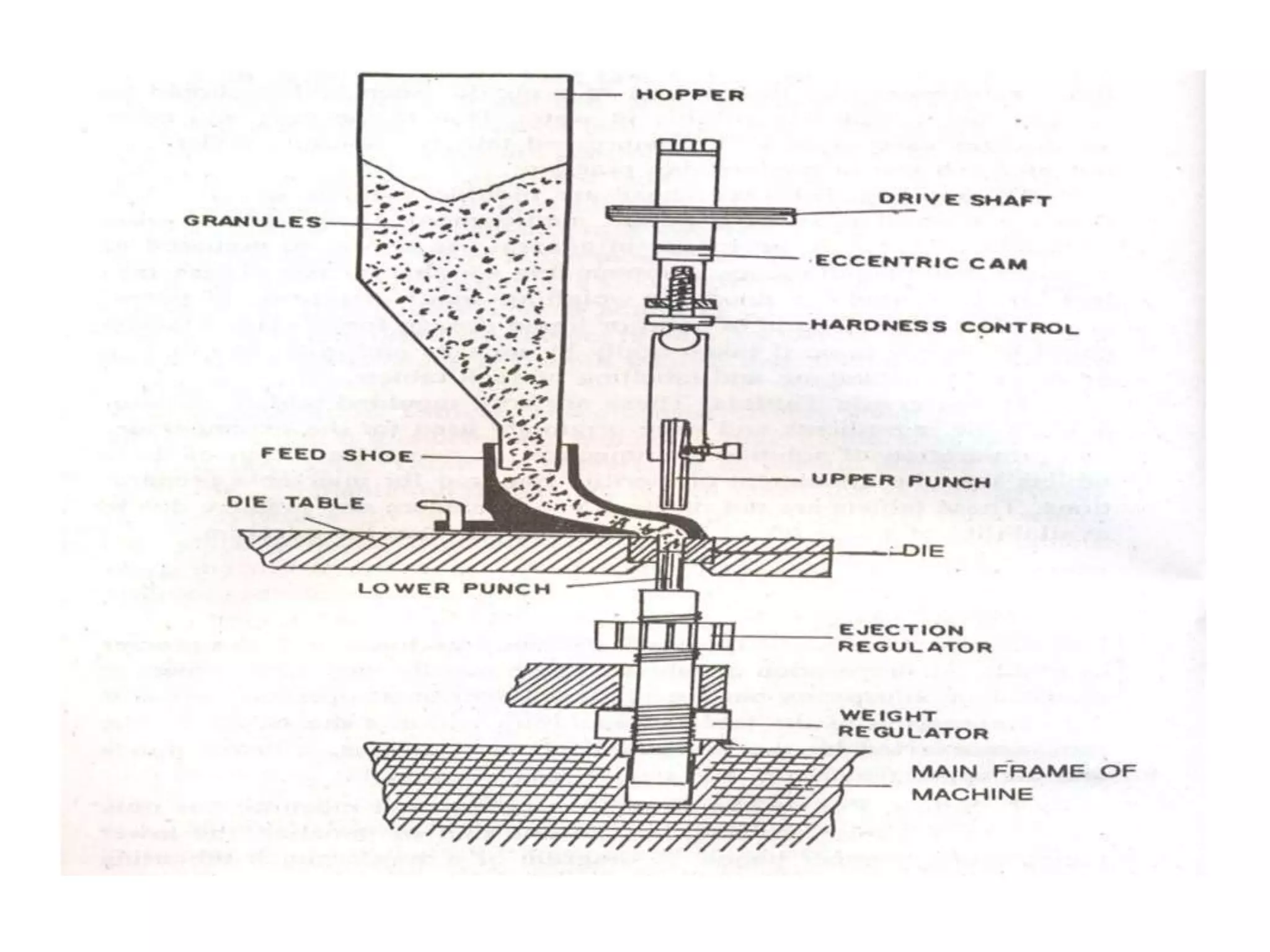

This document summarizes the working of tablet punching machines. It discusses how tablets are formed through the combined pressing action of upper and lower punches in a die. It describes the different types of punches and dies used to form tablets of various shapes. The document also explains the basic parts and working principles of single punch and rotary tablet pressing machines, including the filling, compression, and ejection stages of the tablet formation process. Common problems like capping, lamination, chipping, cracking, sticking, picking and double impressions that can occur during tablet compression are also summarized along with their causes and remedies.