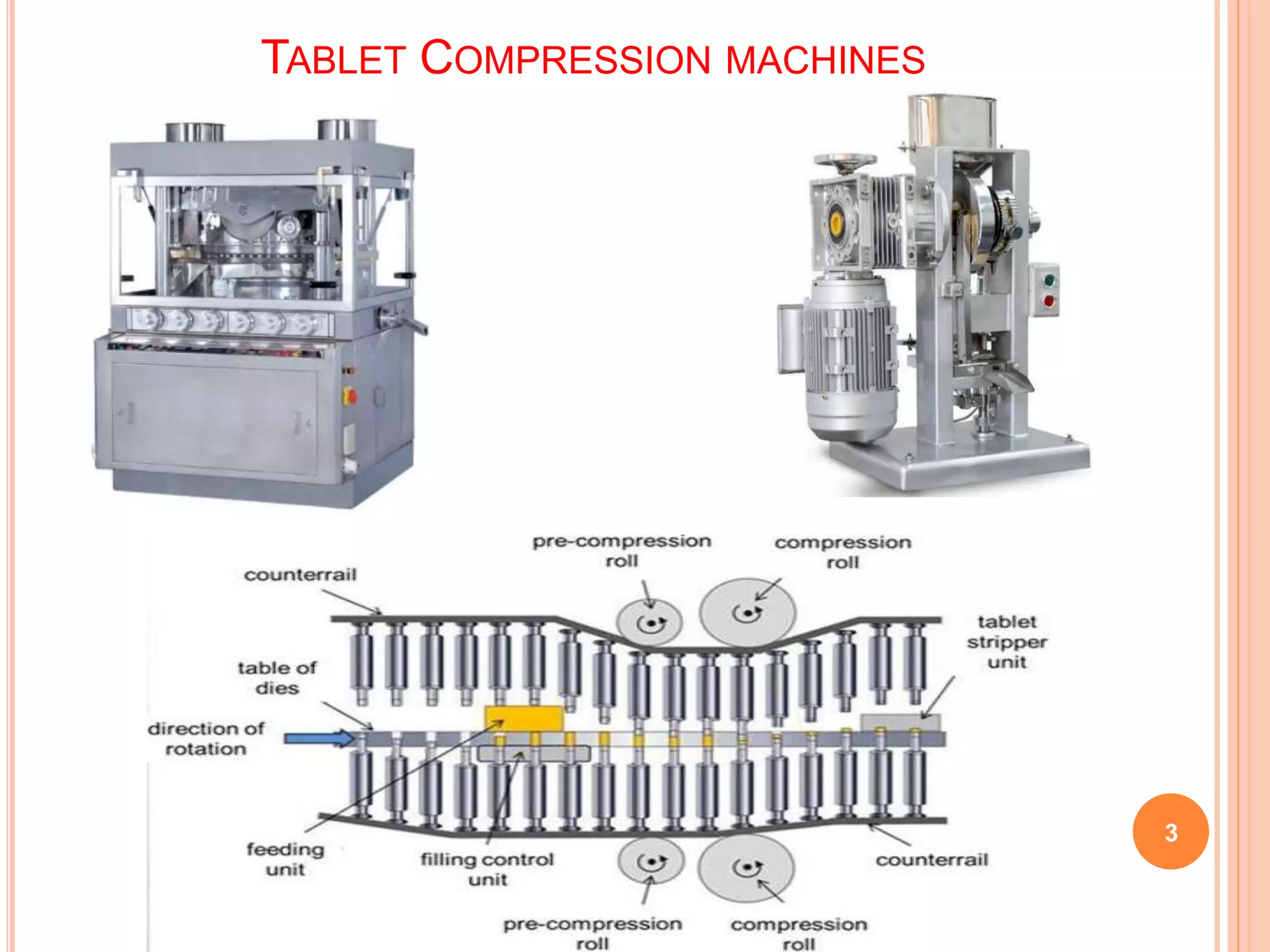

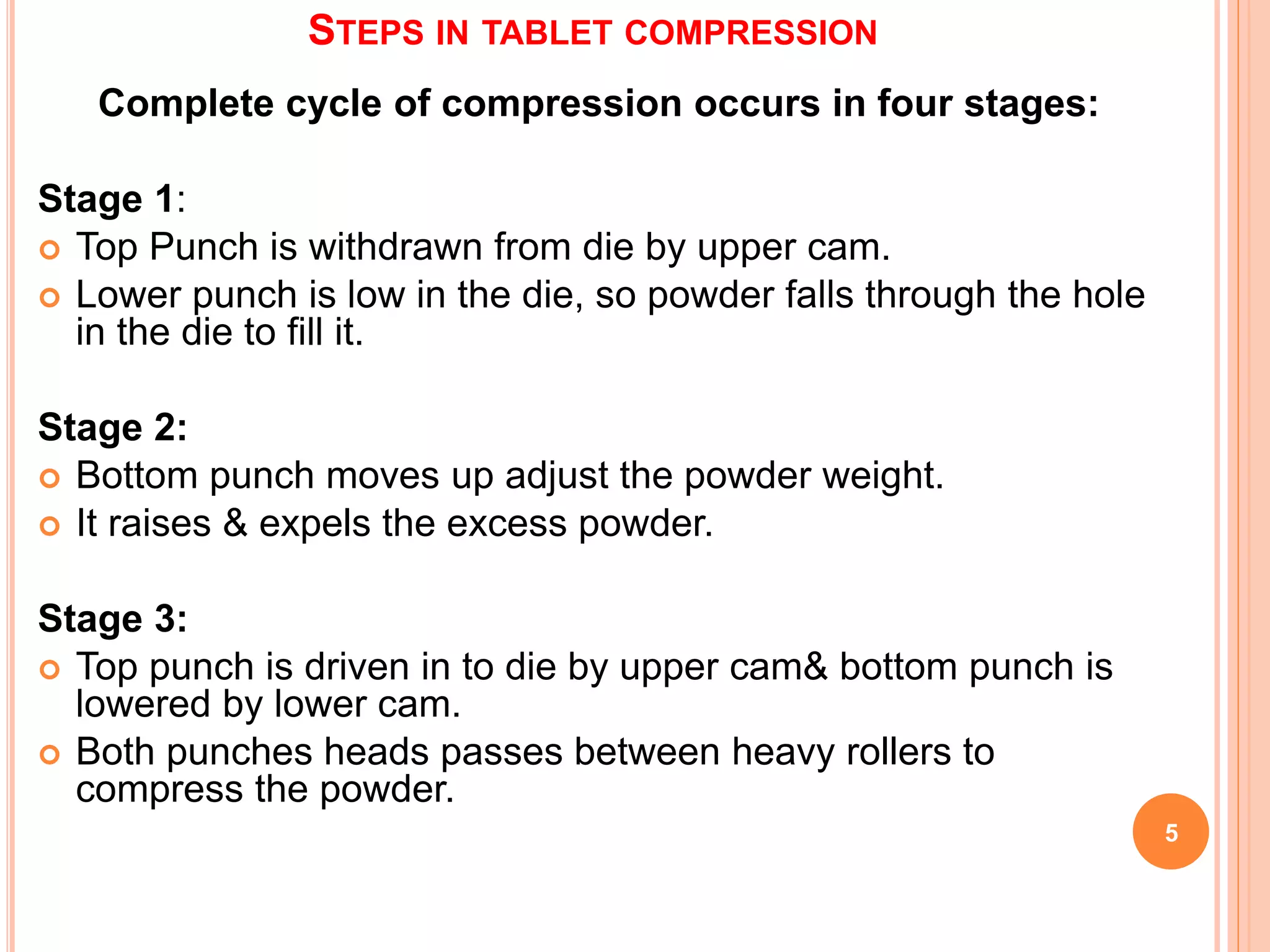

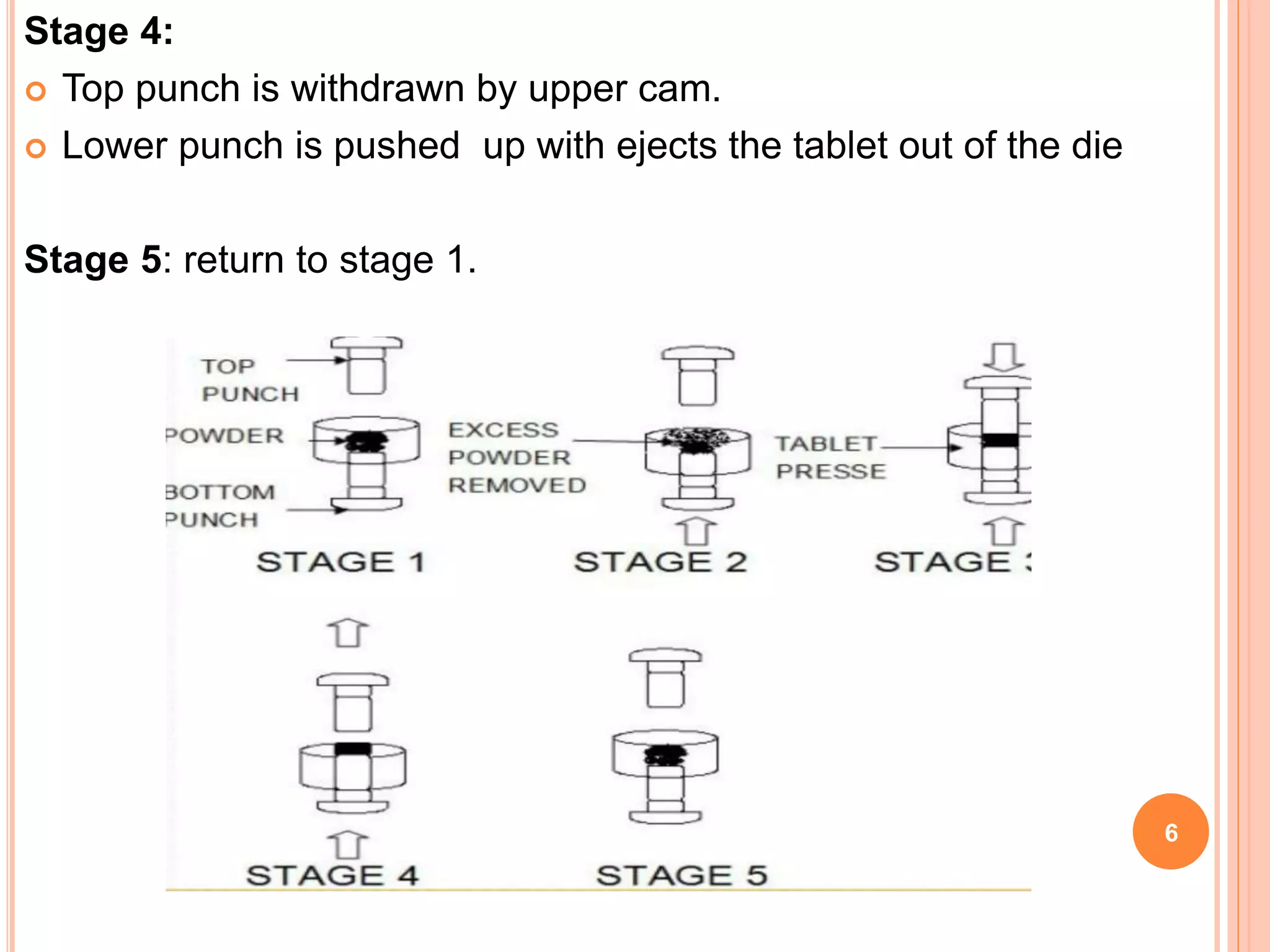

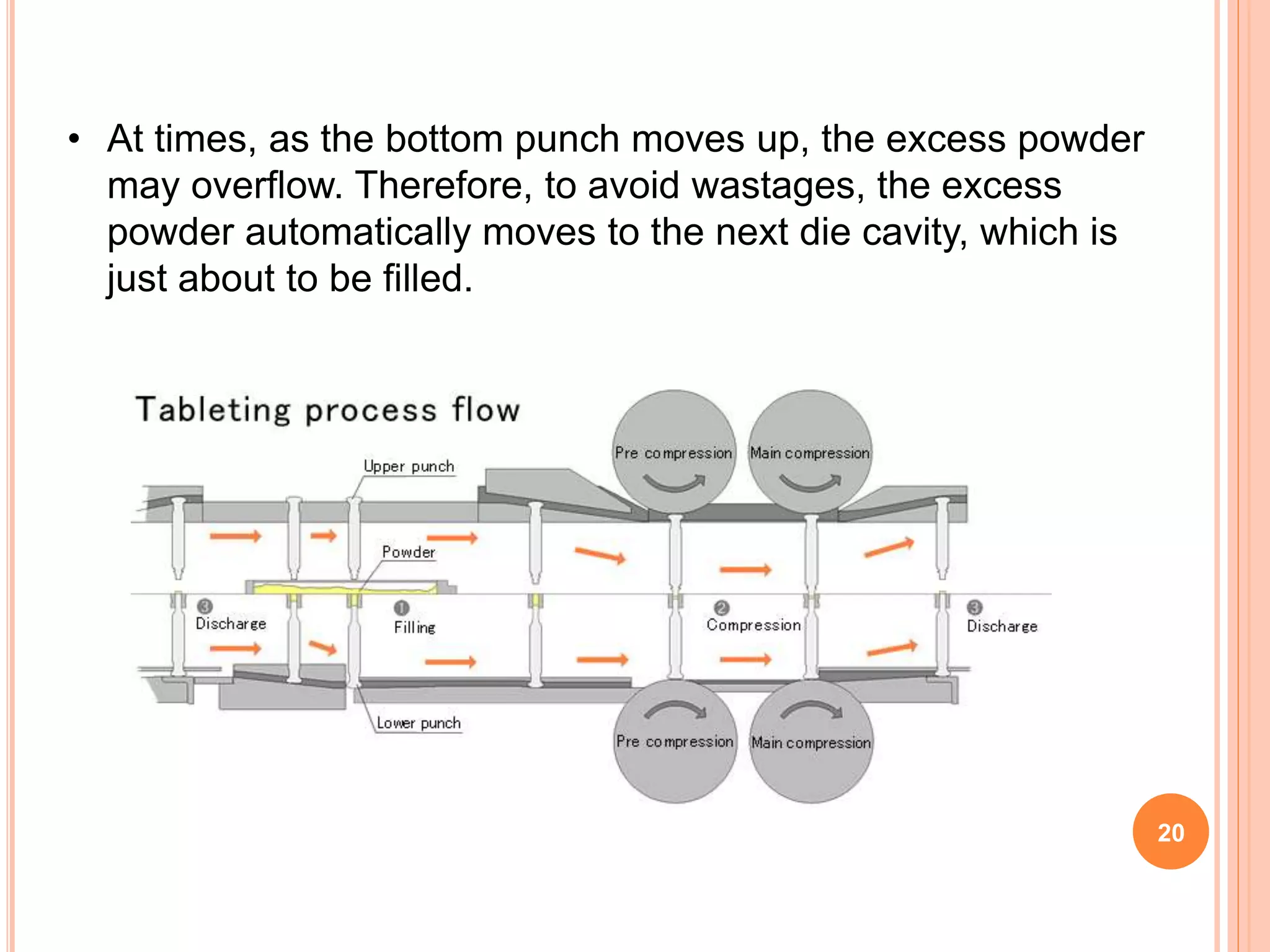

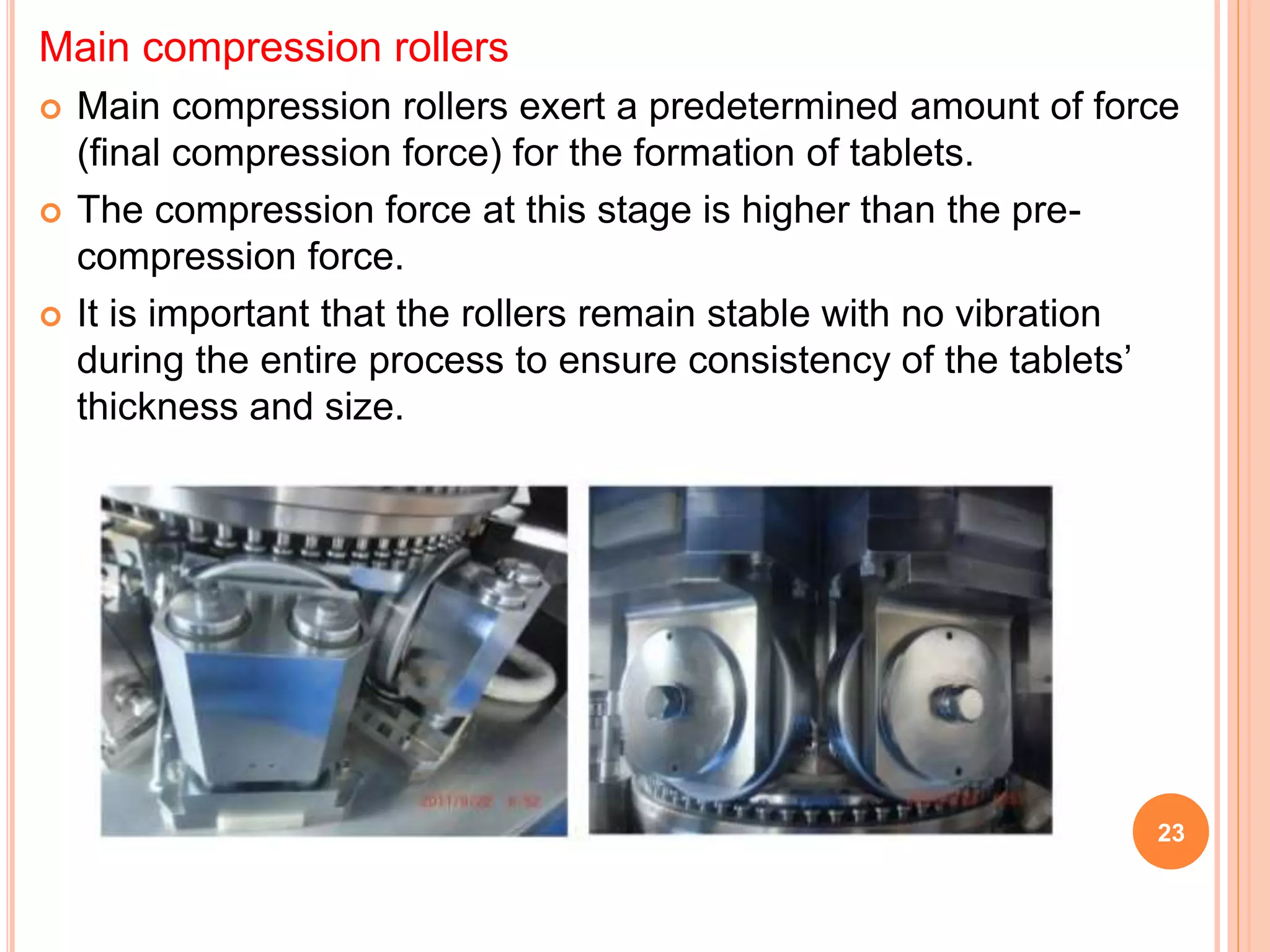

The document describes the process and key components of a tablet compression machine. The machine uses punches and dies to compress powder or granules into tablets. It has several stations that rotate to precisely fill the dies, compress the powder under high pressure, and eject the finished tablets. The main stages are filling the die cavity, adjusting the powder weight, compressing the powder between the punches, and ejecting the tablet. Critical parts include the hopper, feeder system, punches, dies, turret, cam tracks, and rollers which work together to automate tablet production.