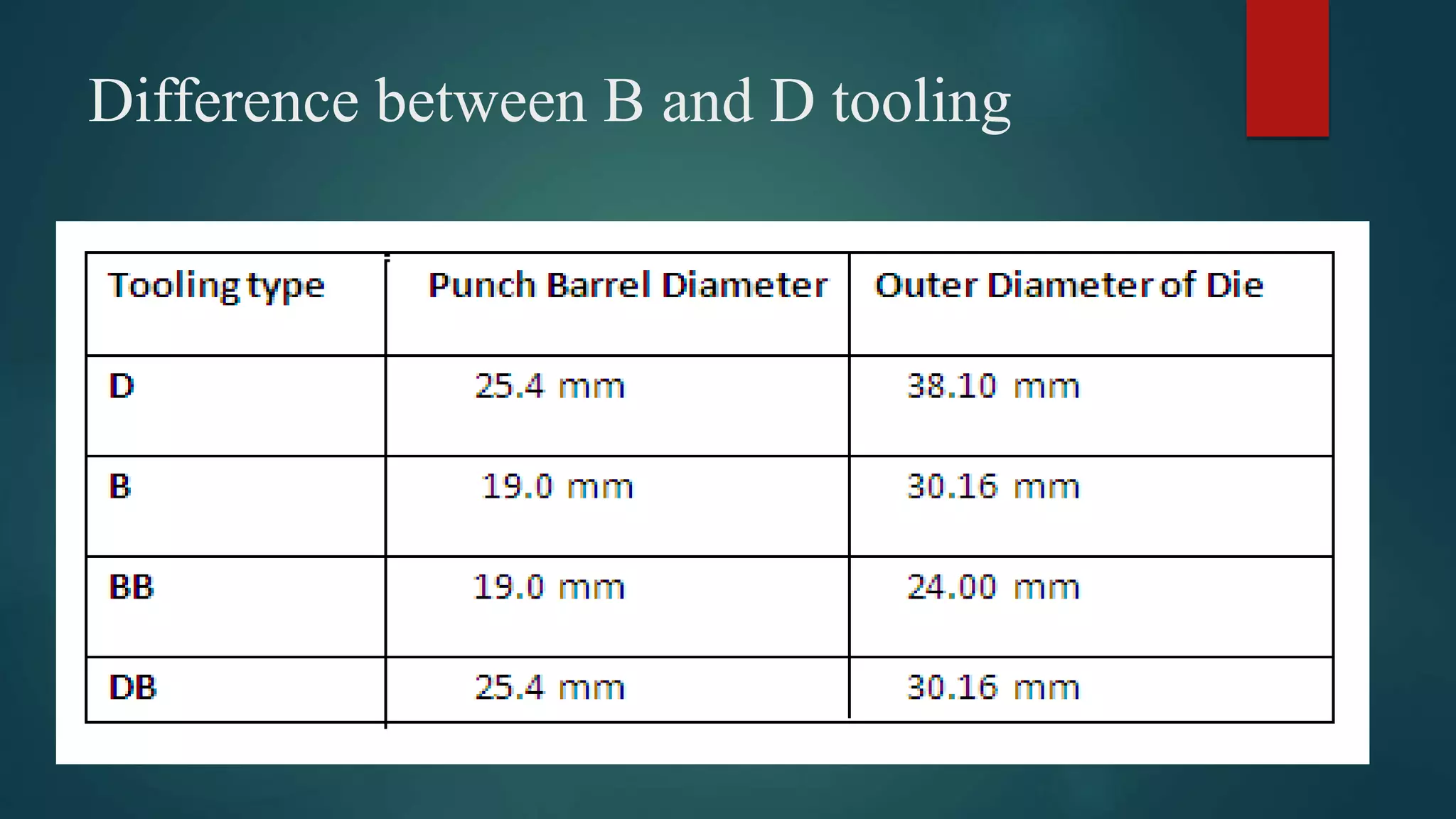

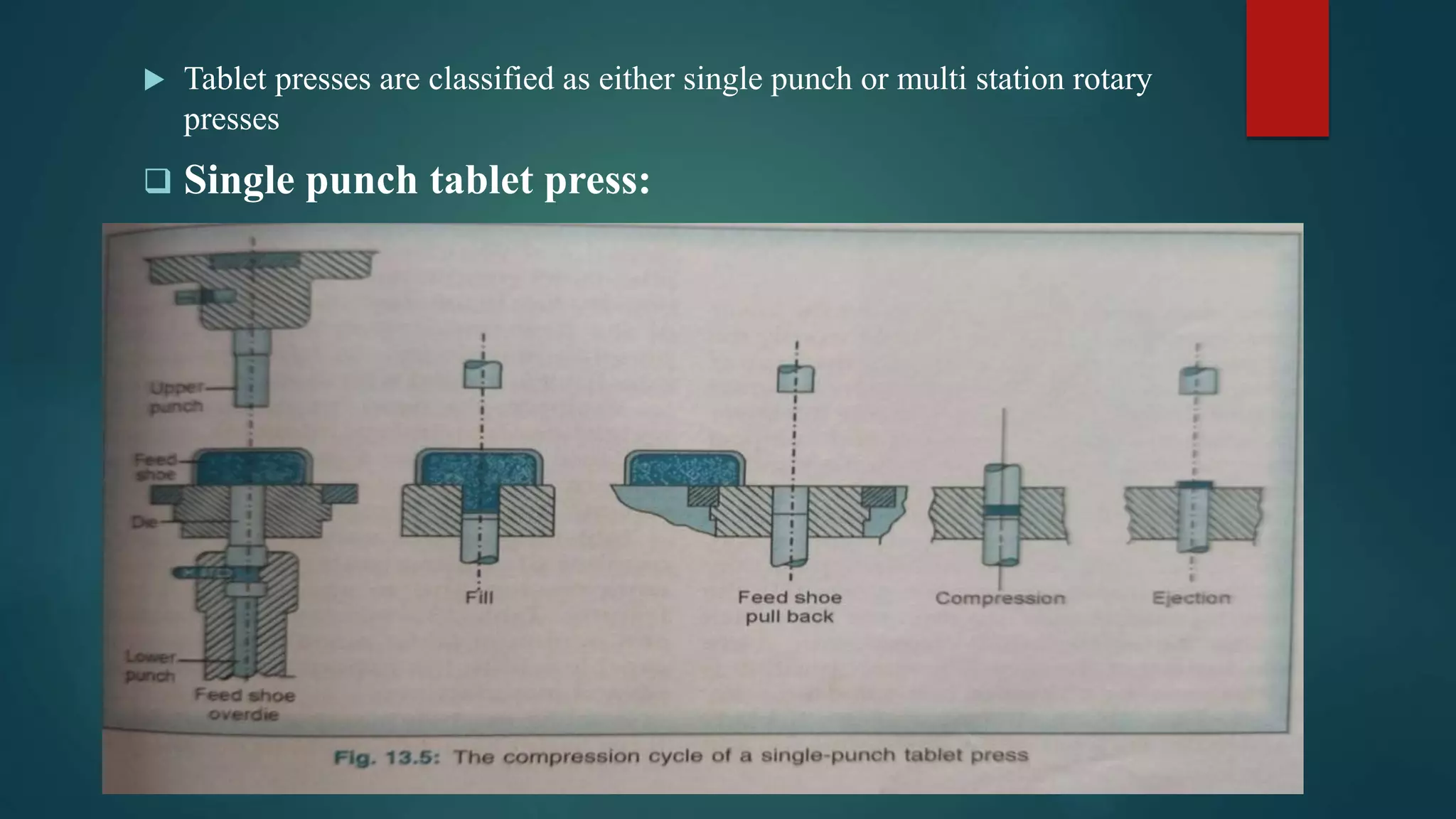

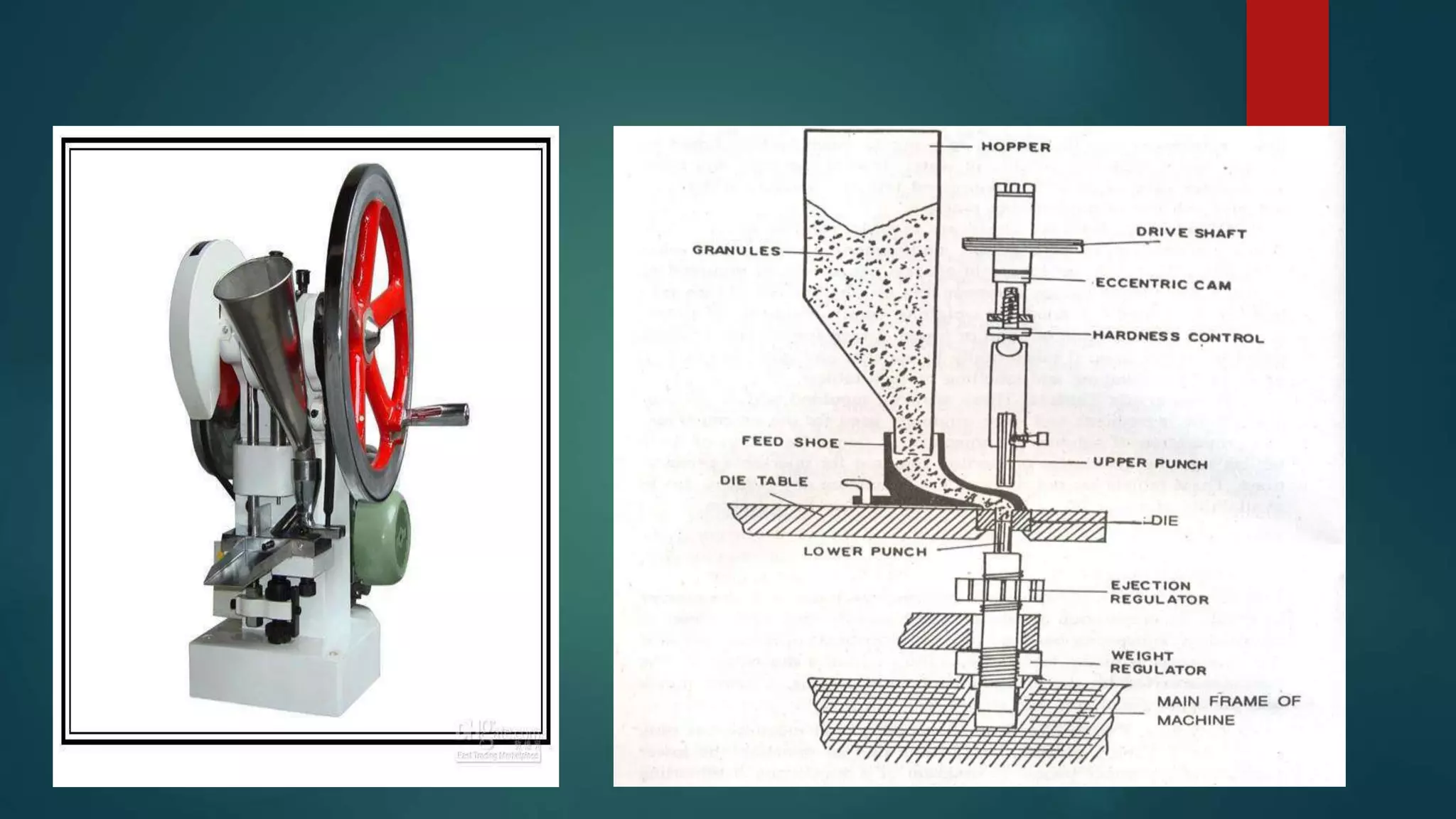

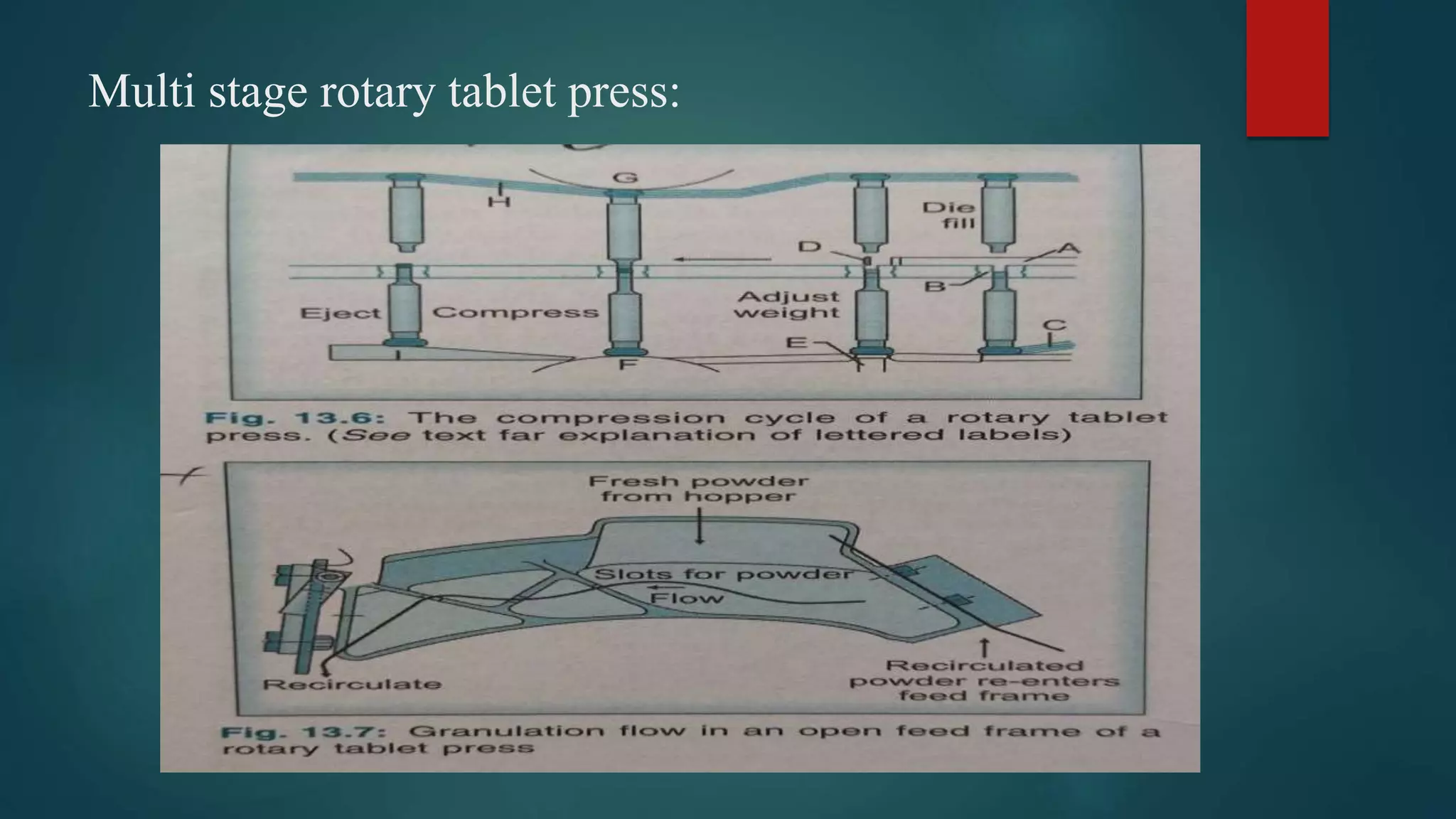

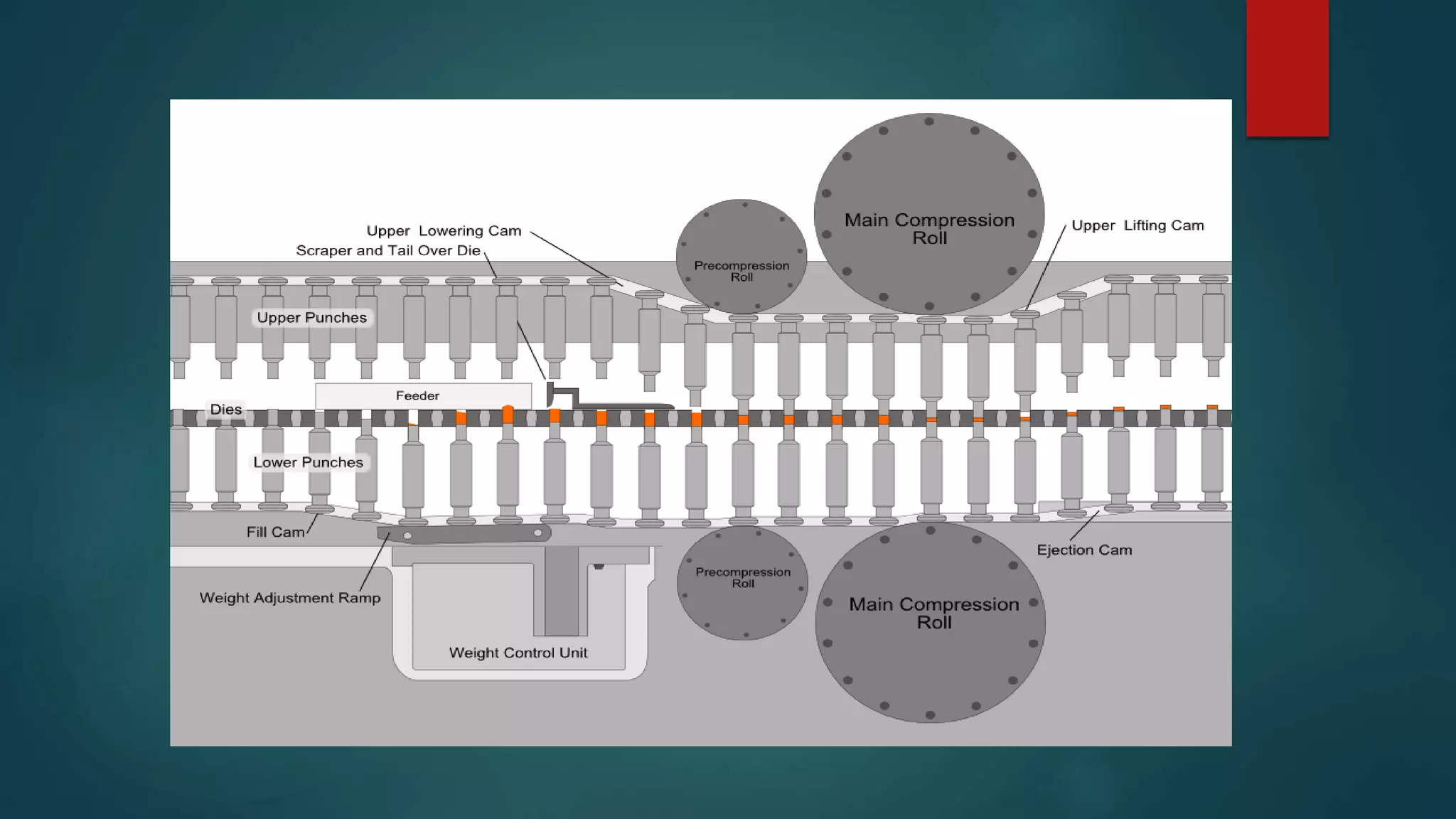

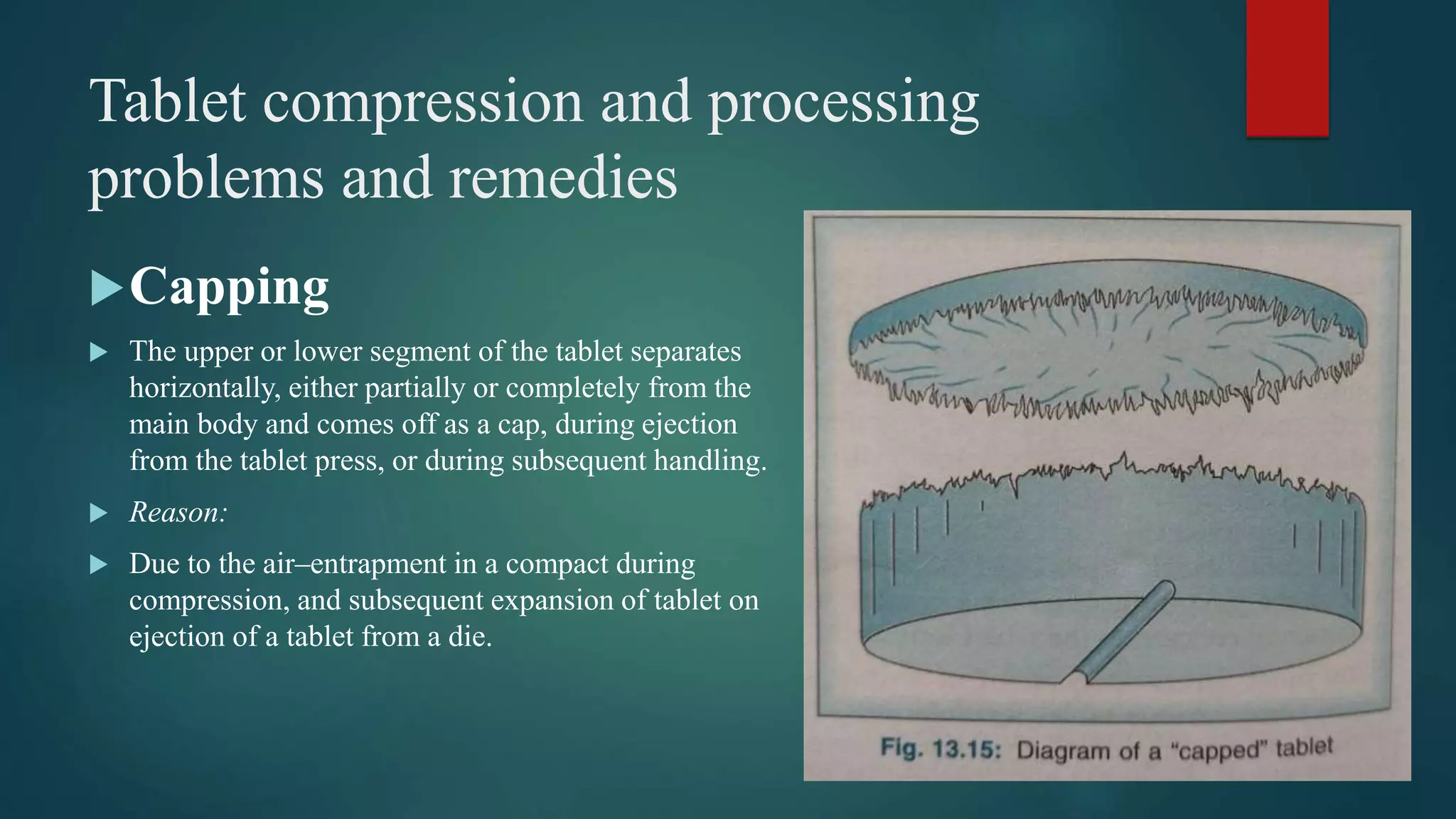

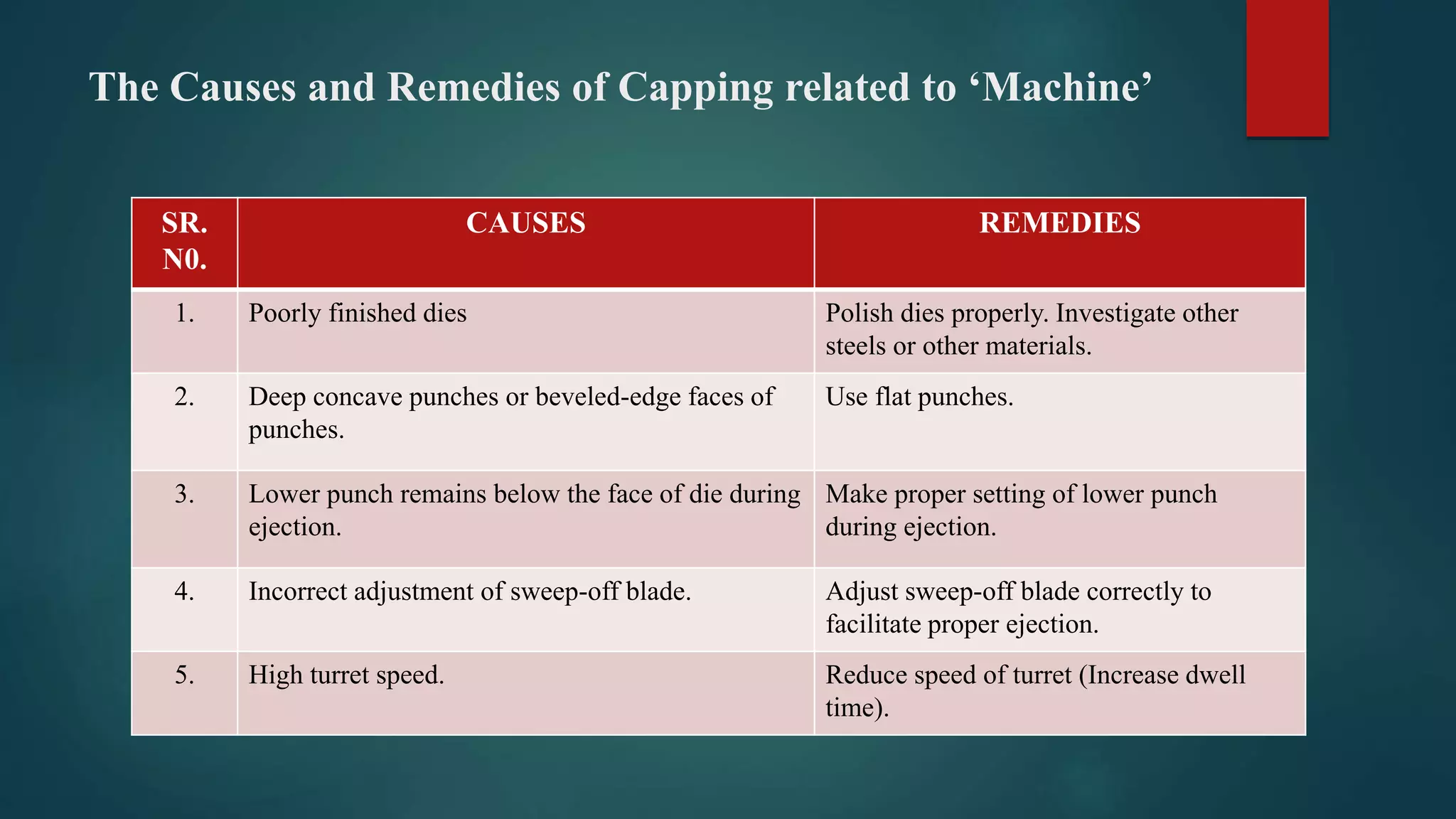

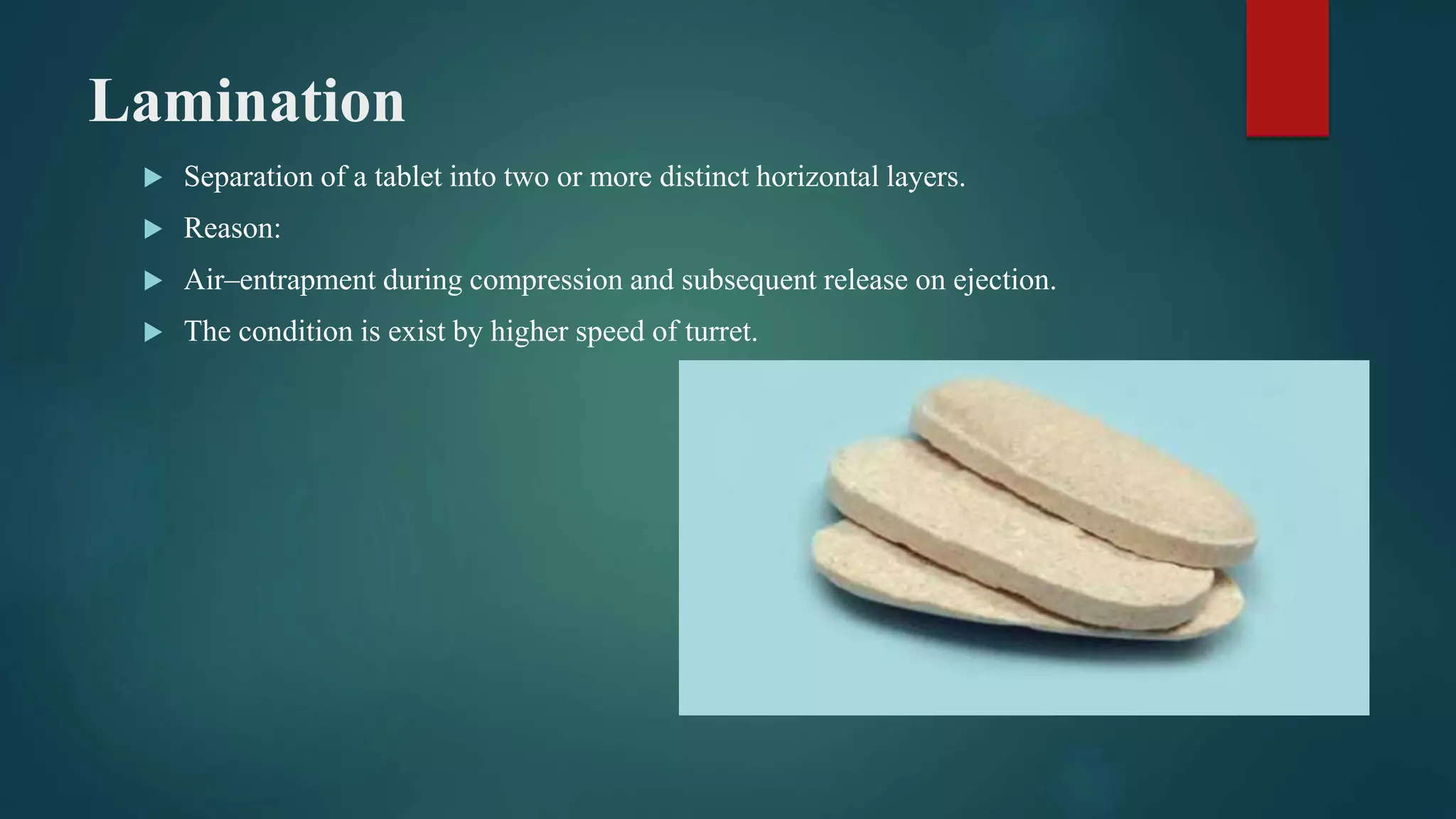

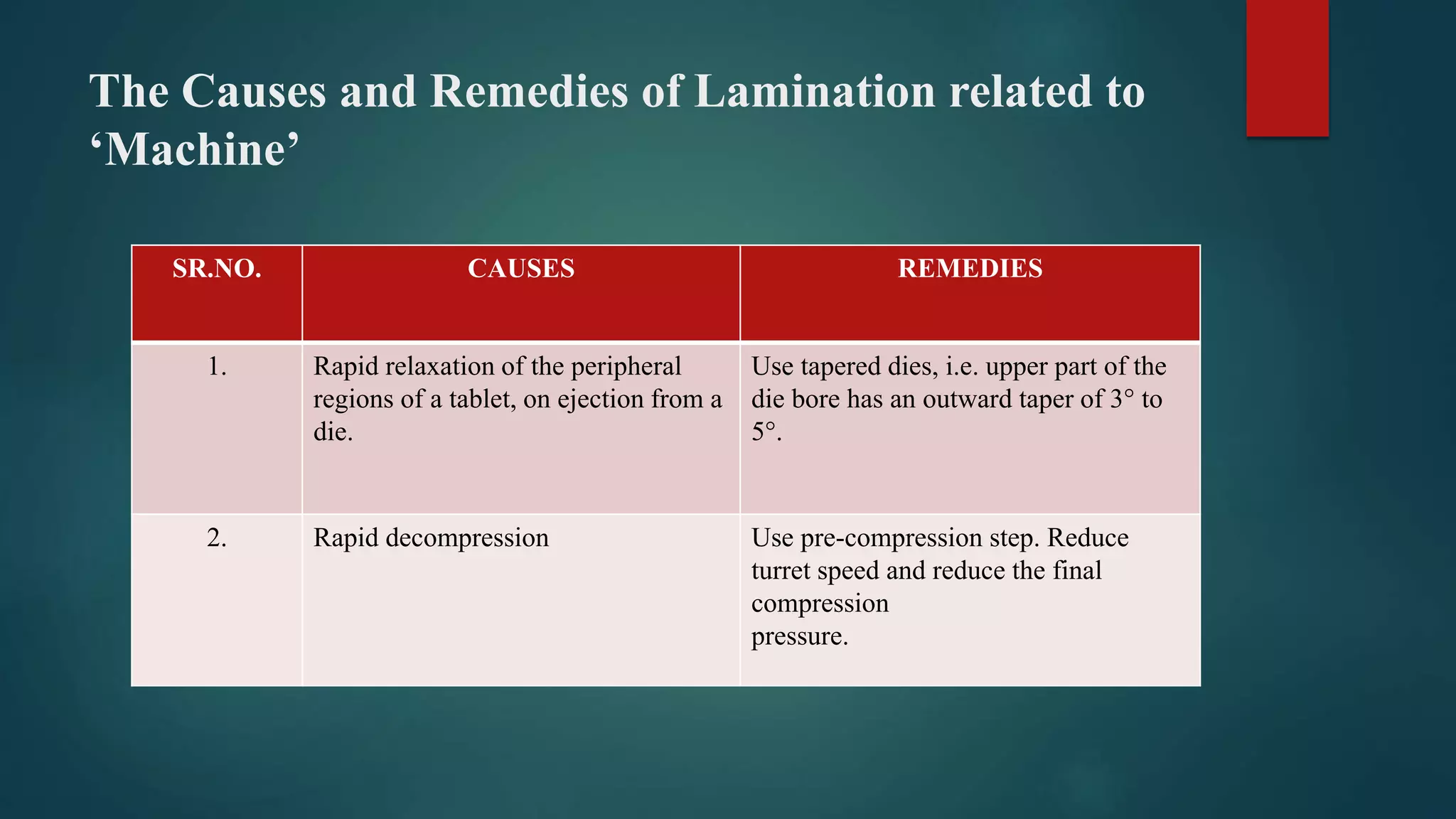

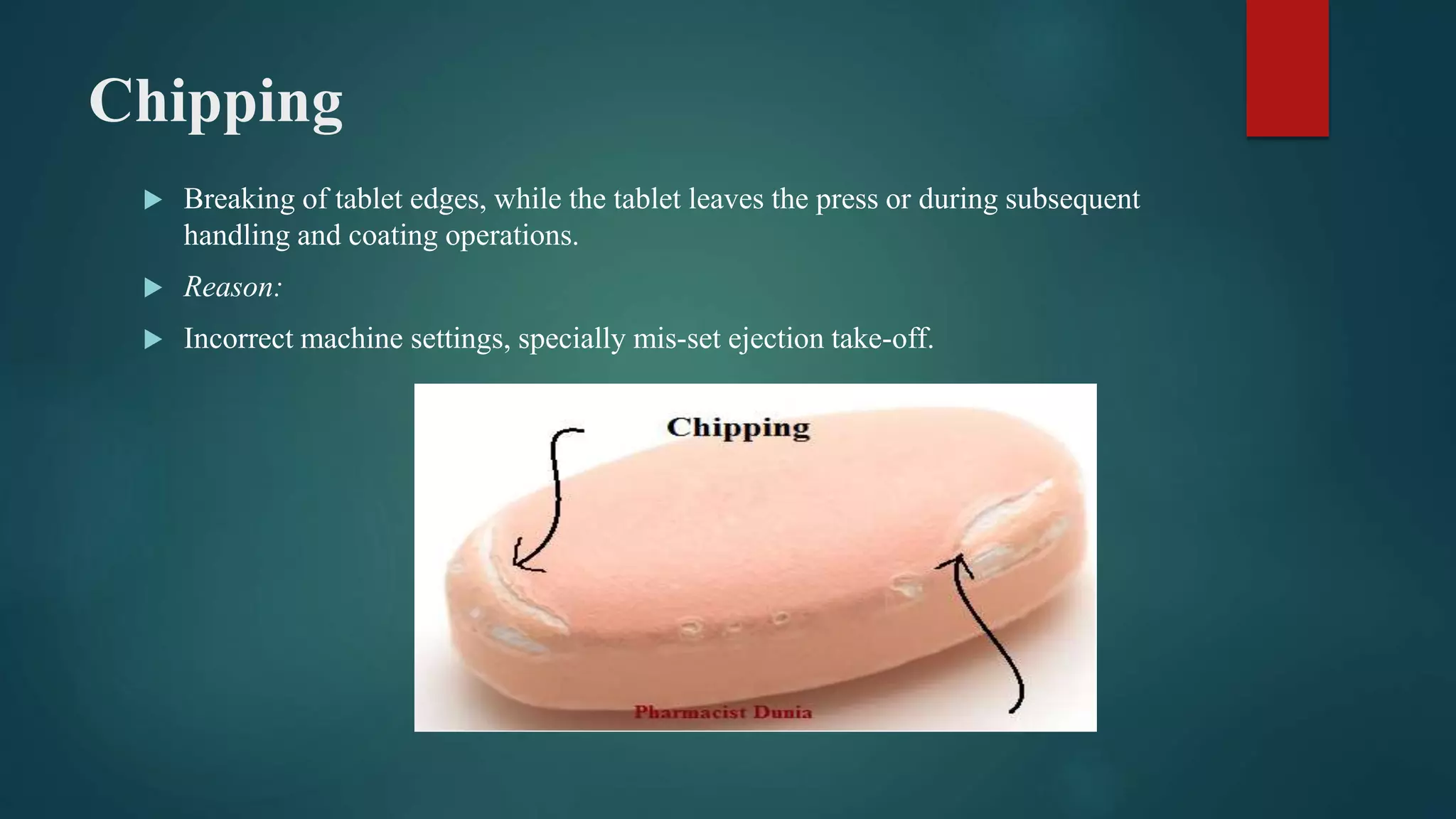

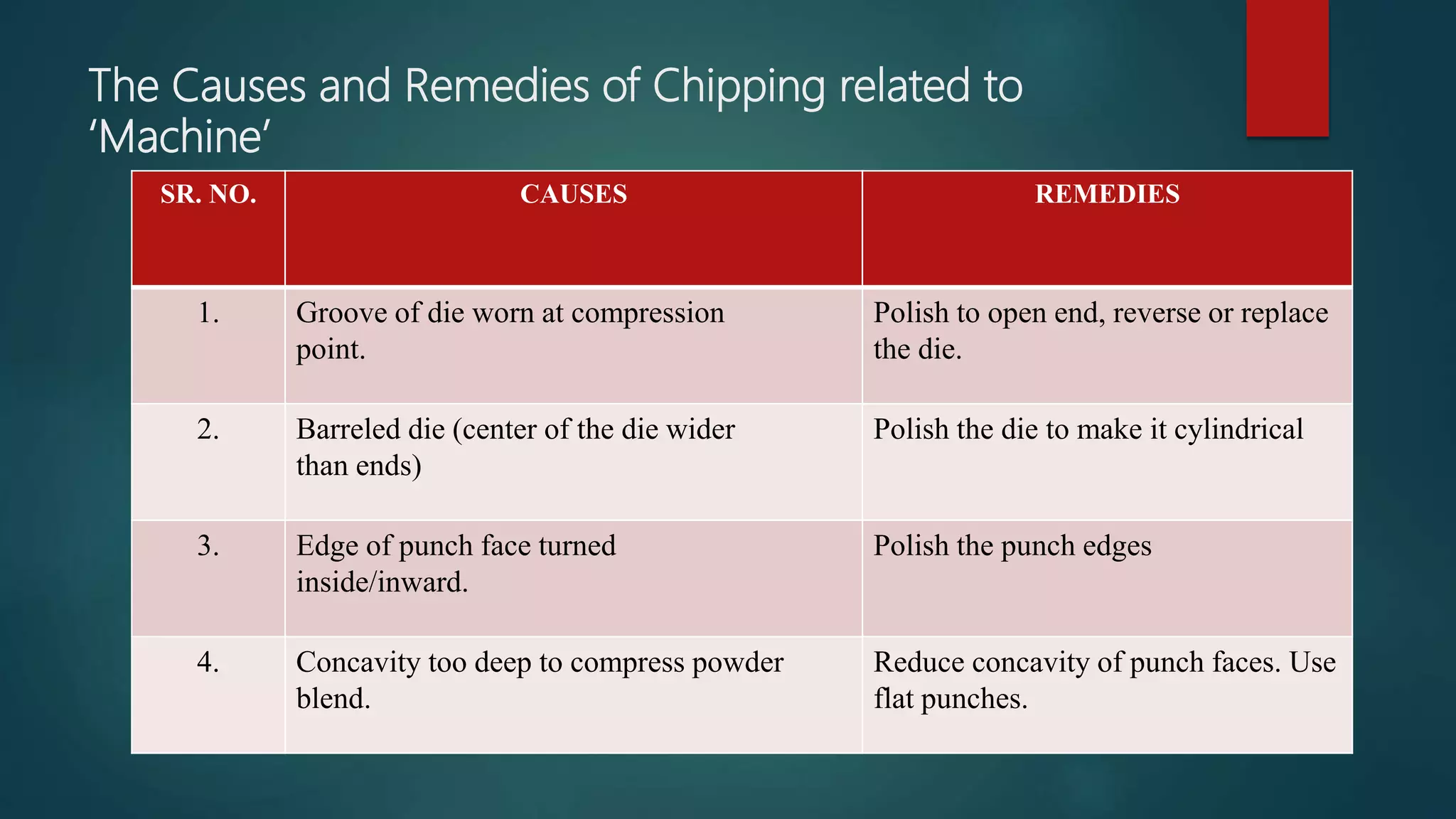

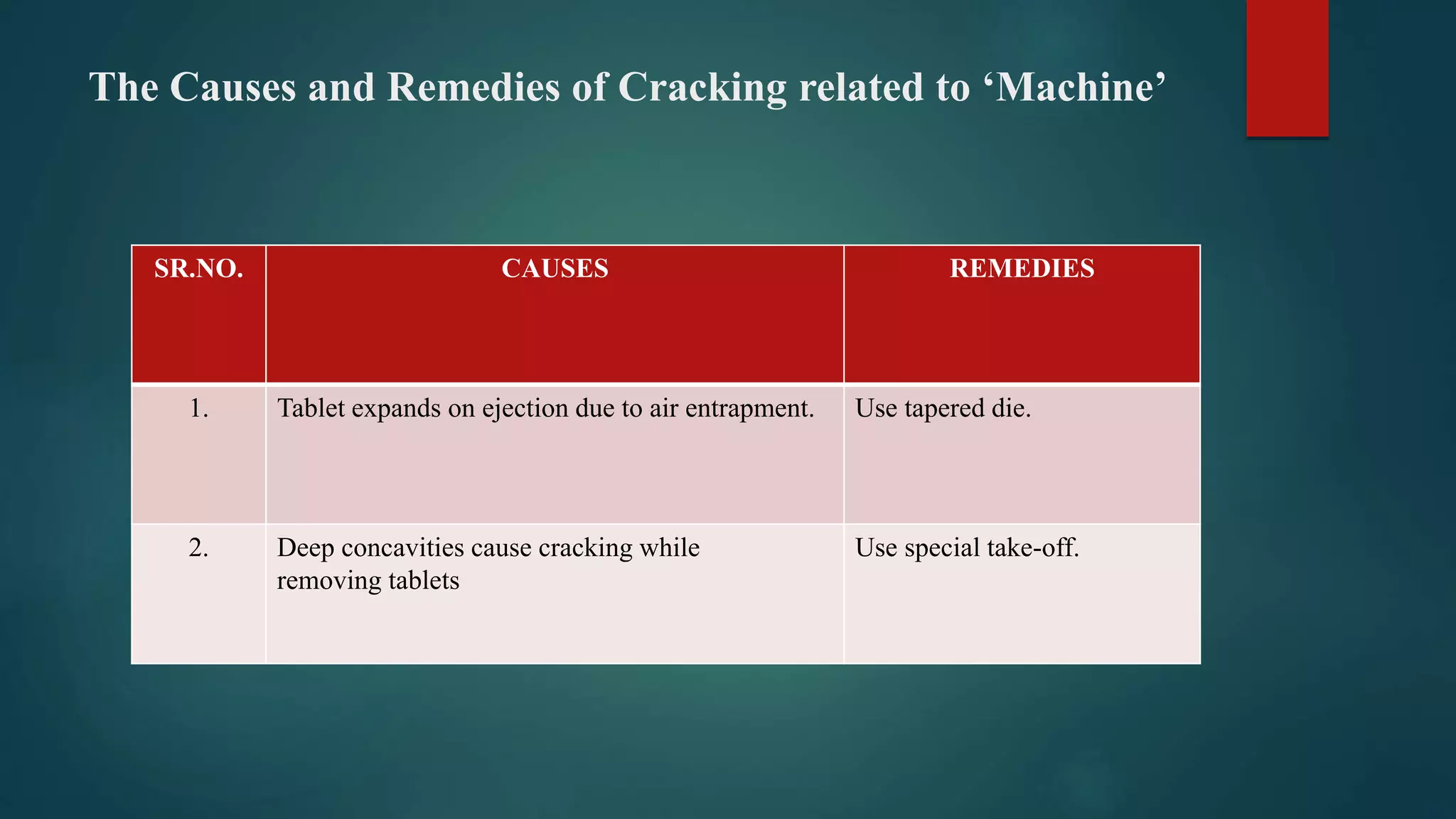

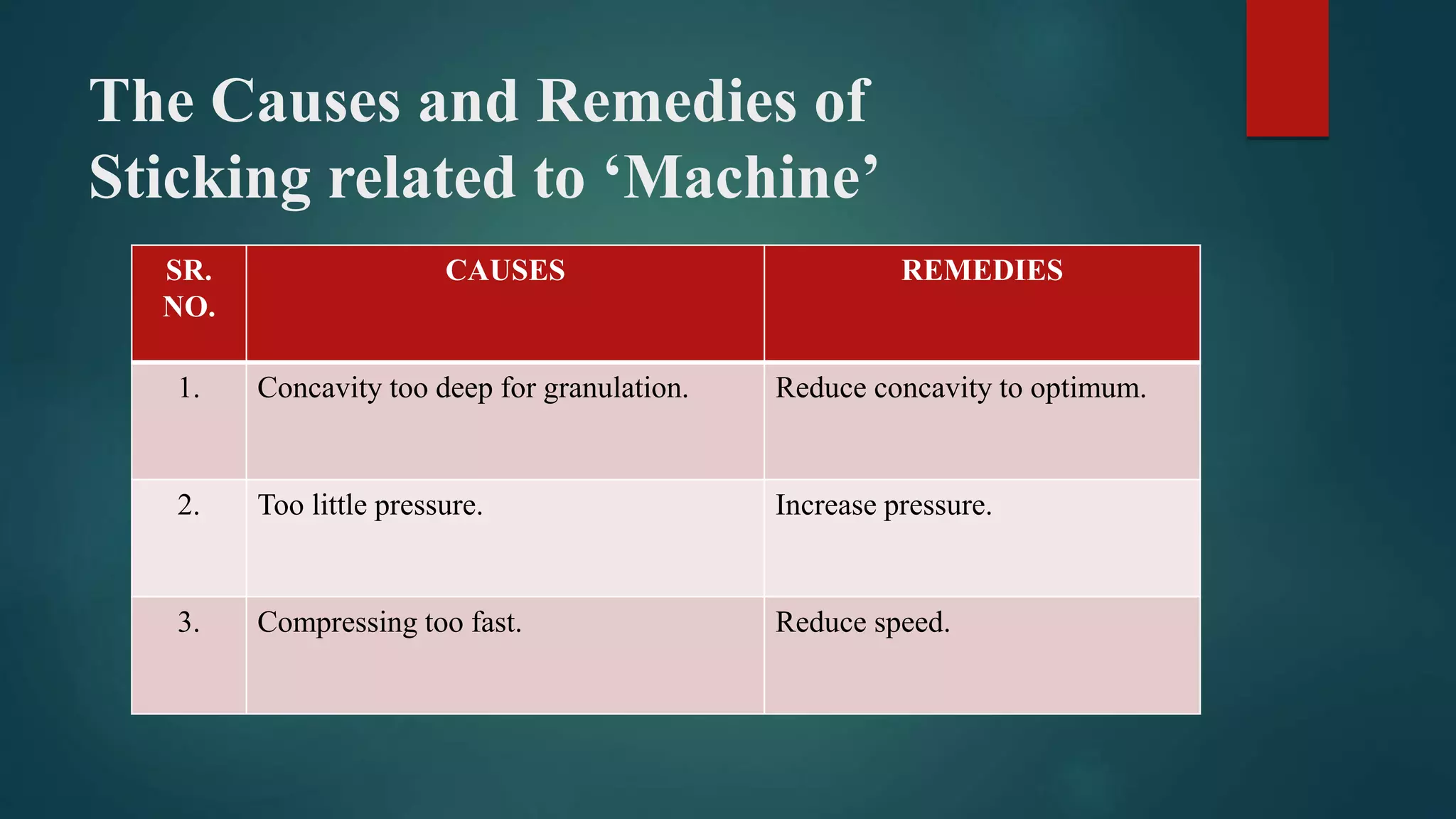

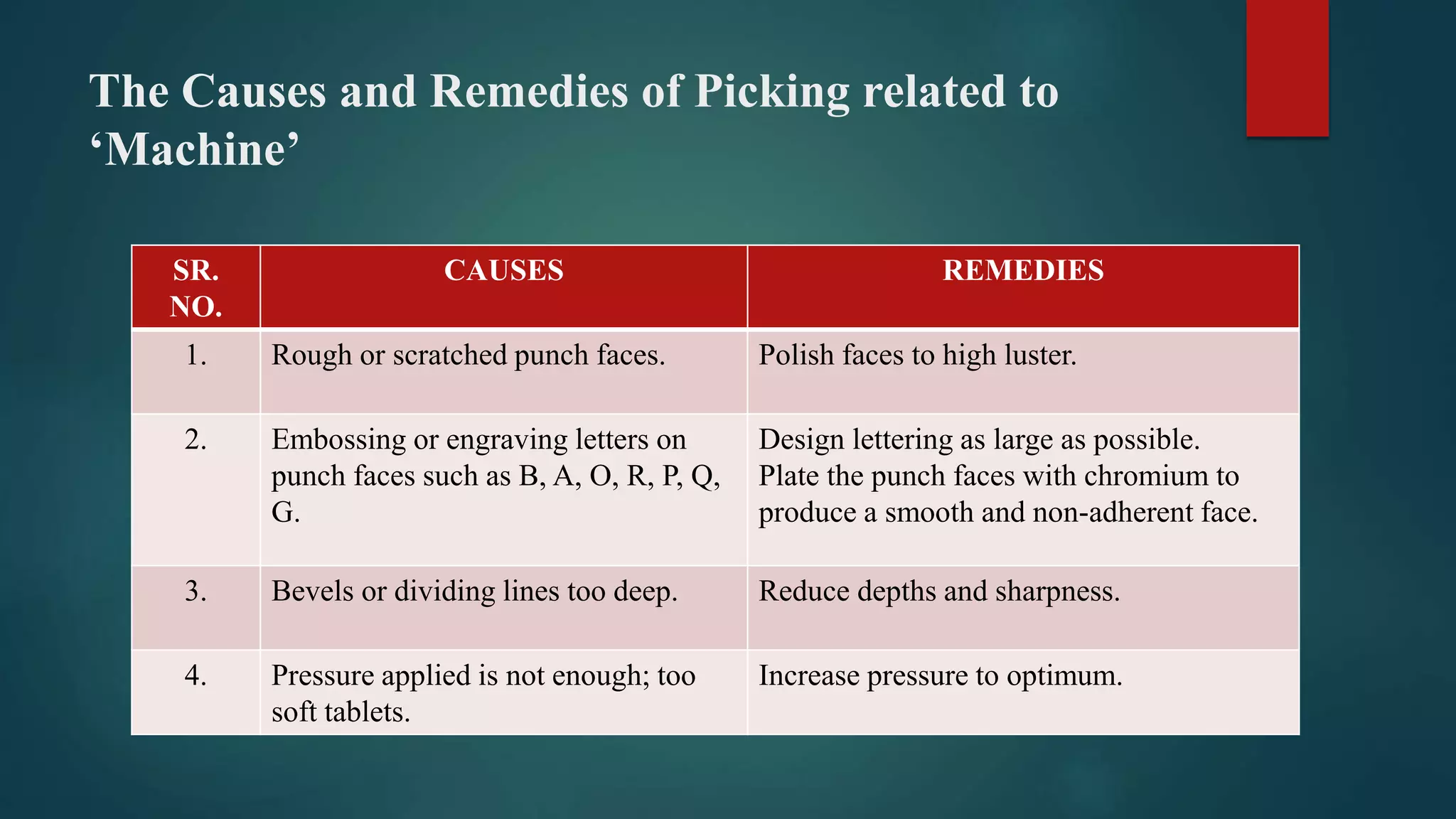

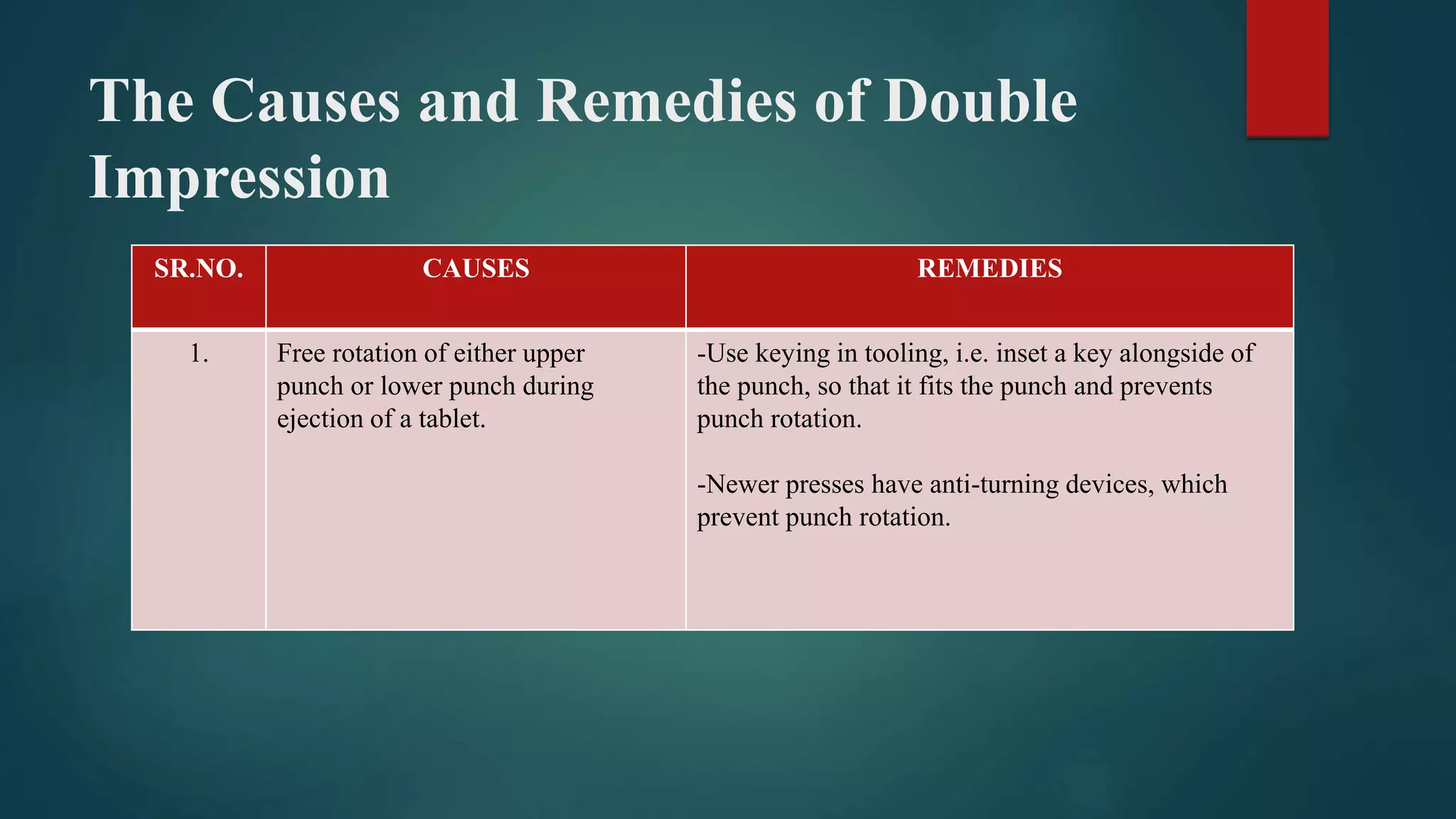

Tablet compression machines compress granules into tablets using dies and punches. There are single punch and multi-station rotary presses. Compression problems include capping, lamination, chipping, cracking, sticking, picking, and double impressions. Capping is caused by air entrapment during compression. Lamination occurs from air entrapment and high turret speeds. Machine settings and worn tools can cause chipping. Rapid tablet expansion from deep concave punches causes cracking. Improperly dried granules can cause sticking and picking. Punches rotating during ejection can cause double impressions. Solutions involve adjusting machine settings, tooling design, and processing parameters.