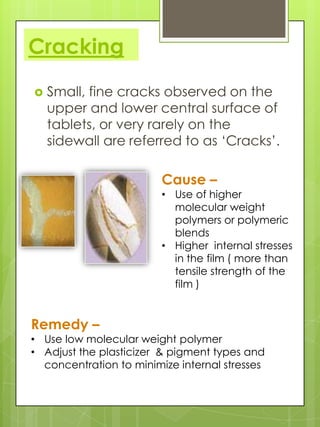

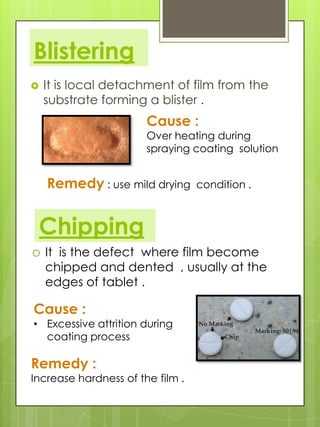

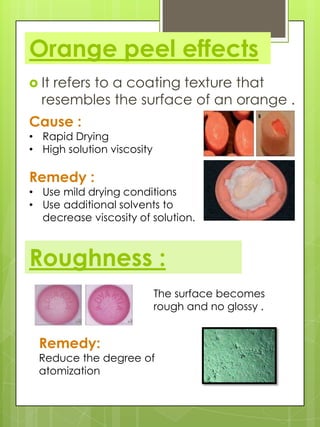

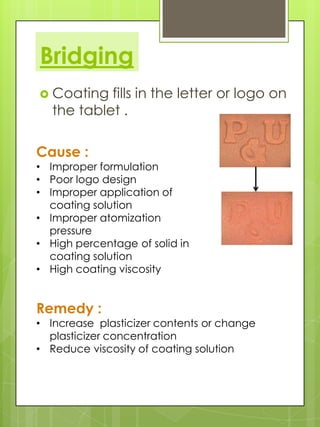

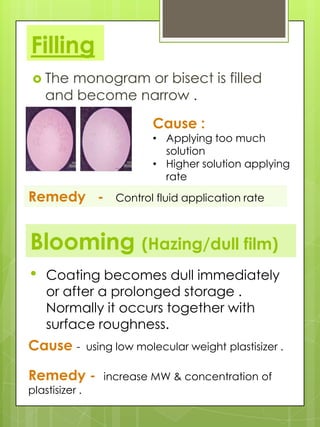

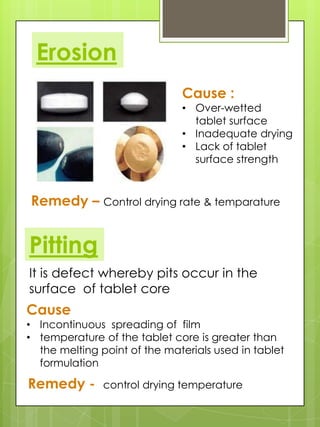

Tablet coating involves covering tablets with mixtures like resins, gums, and sugars to improve properties like taste, stability, and effectiveness. Common coating defects include twinning where tablets stick together, cracking or roughness of the film, and variations in color. The document outlines several specific coating defects like orange peel, bridging, chipping, and lists possible causes like inefficient drying, high viscosity, or improper application and remedies like reducing spray rates or changing plasticizer.