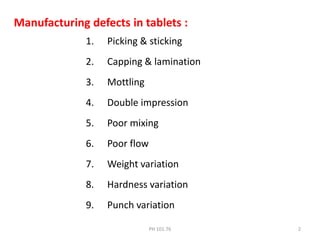

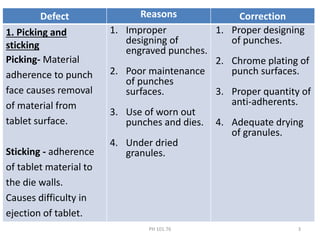

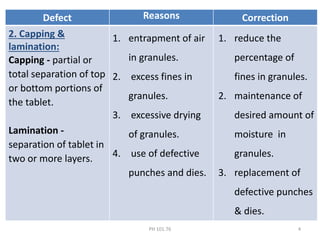

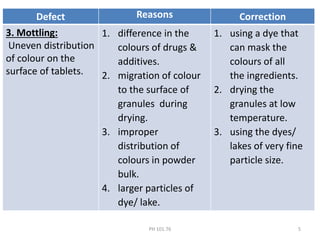

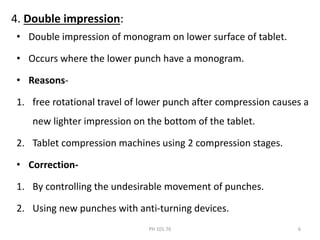

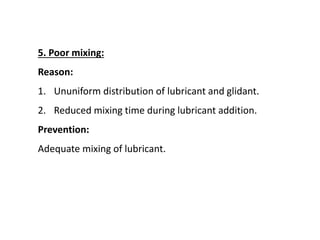

This document discusses common manufacturing defects that can occur during tablet production such as picking and sticking, capping and lamination, mottling, double impression, poor mixing, poor flow, weight variation, and hardness variation. For each defect, the document provides the reason for why the defect occurs and recommendations for how to correct the issue, such as using properly designed punches, adequate drying, uniform granule size distribution, and controlling punch movement. The overall goal of the document is to outline typical tablet defects, their causes, and methods for prevention.