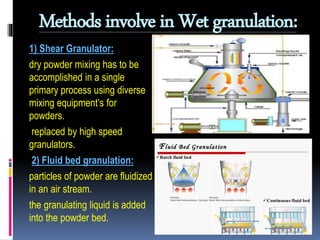

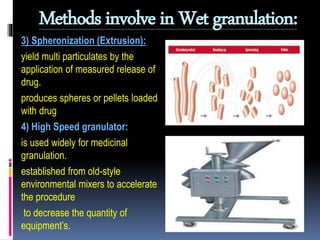

Wet granulation is a process that uses a granulating liquid like ethanol or water to mix powder particles. It involves mixing powders and a binder solution, sieving the wet mixture, drying the granules, and sieving the dry granules. Common methods are shear granulation, fluid bed granulation, and spheronization which forms spheres or pellets. Wet granulation produces granules that compress well and result in tablets with consistent properties, though it uses more energy than dry granulation and powders must be stable with water.