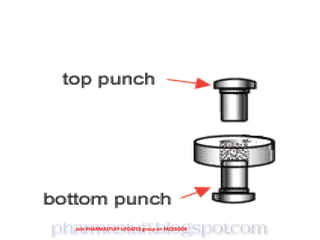

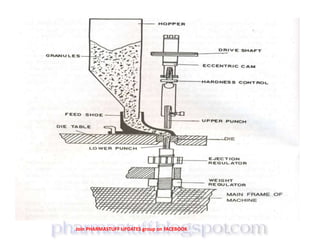

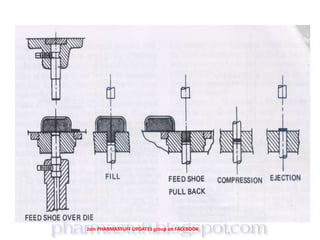

The document explains the operation of a single punch tablet press, which is a simple machine used for tablet manufacturing that involves a die and a pair of upper and lower punches. It outlines the key components, such as the hopper and feeding mechanism, as well as the stages of tablet compression: filling, compression, and ejection. The tablet press offers several advantages, including ease of operation, high utilization, and effective control over raw material loading and tablet thickness.