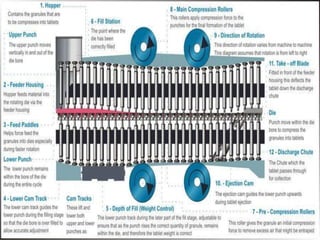

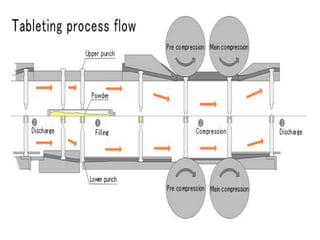

- Tablet compression machines use punches and dies to compress powder ingredients into tablets of precise shapes and sizes.

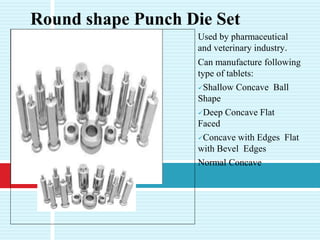

- They can produce tablets in round, oval, or other geometric shapes, and can imprint logos or text on the tablets.

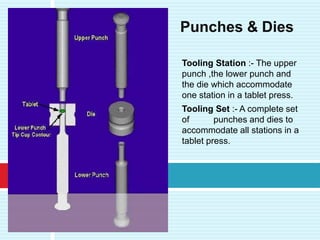

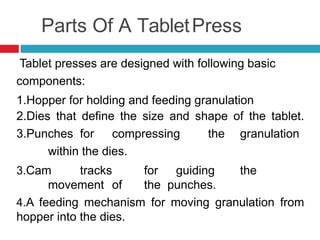

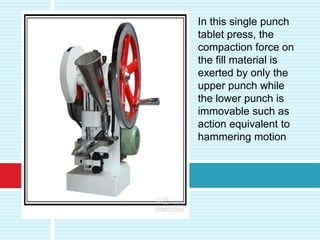

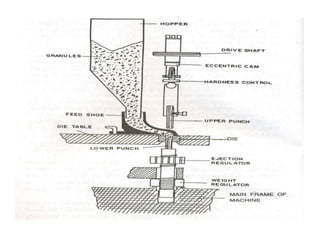

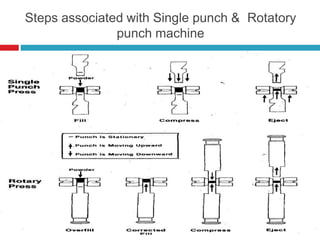

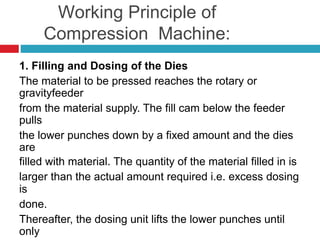

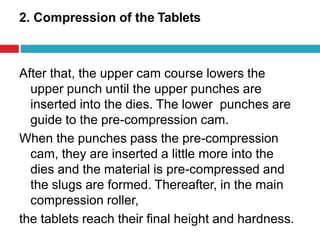

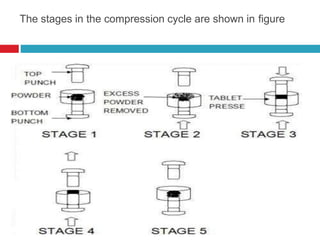

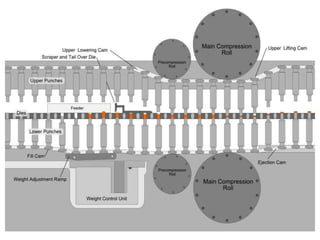

- Tablet presses work by filling powder into dies, then pressing the powder between an upper and lower punch to form tablets.

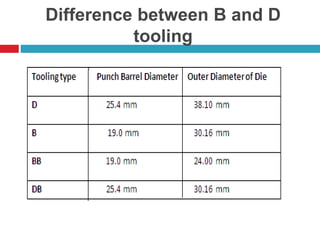

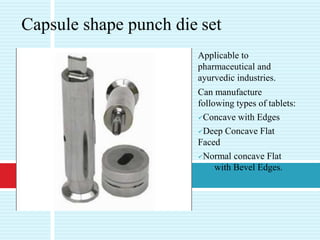

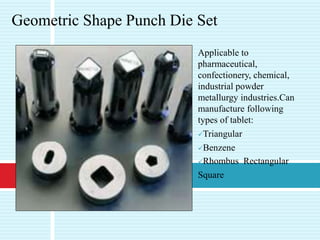

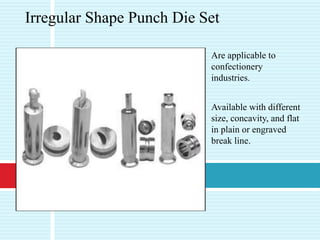

- Punches and dies come in different types depending on the tablet shape needed, such as round, oval, capsule, or irregular shapes.