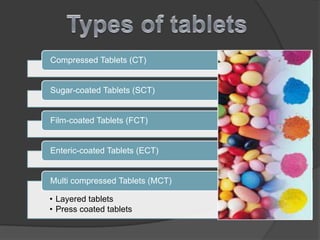

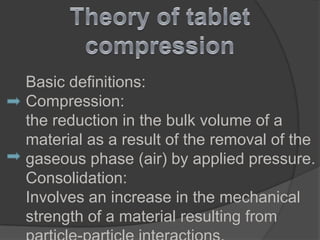

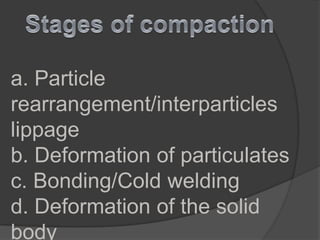

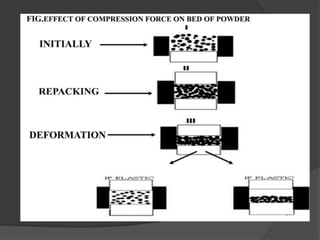

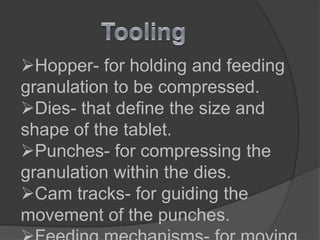

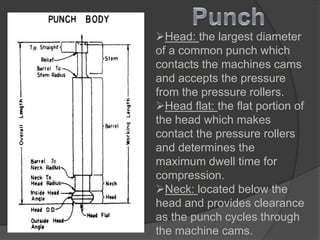

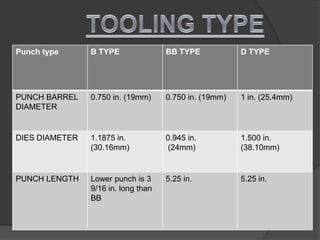

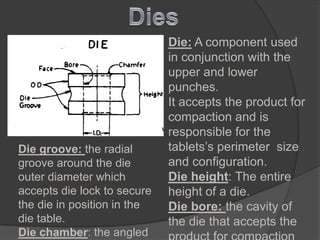

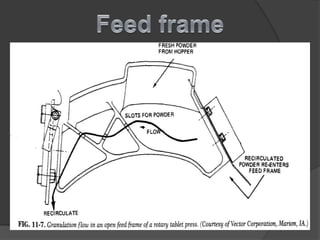

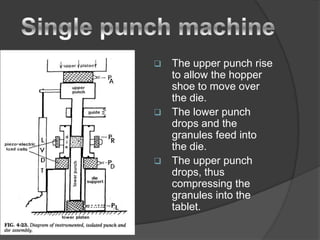

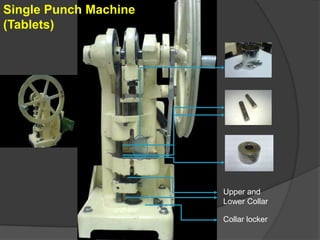

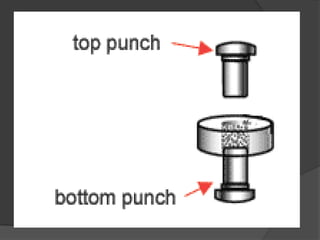

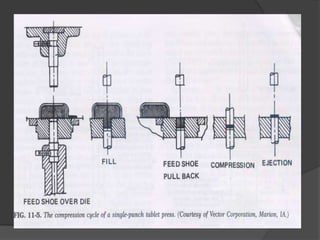

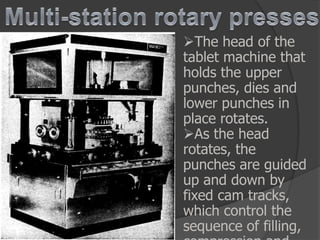

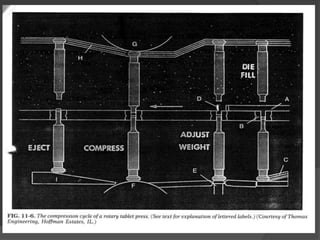

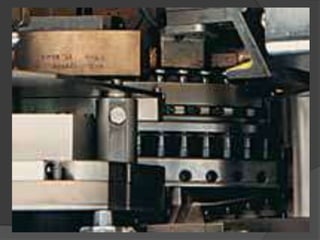

The document summarizes the history and development of tablet manufacturing technology from the 19th century to modern times. It describes key innovations like the rotary tablet press in 1874 and new coating methods in the late 19th century. It also provides definitions and explanations of important compression and compaction concepts. Finally, it discusses the components and functioning of both single punch and rotary tablet presses.