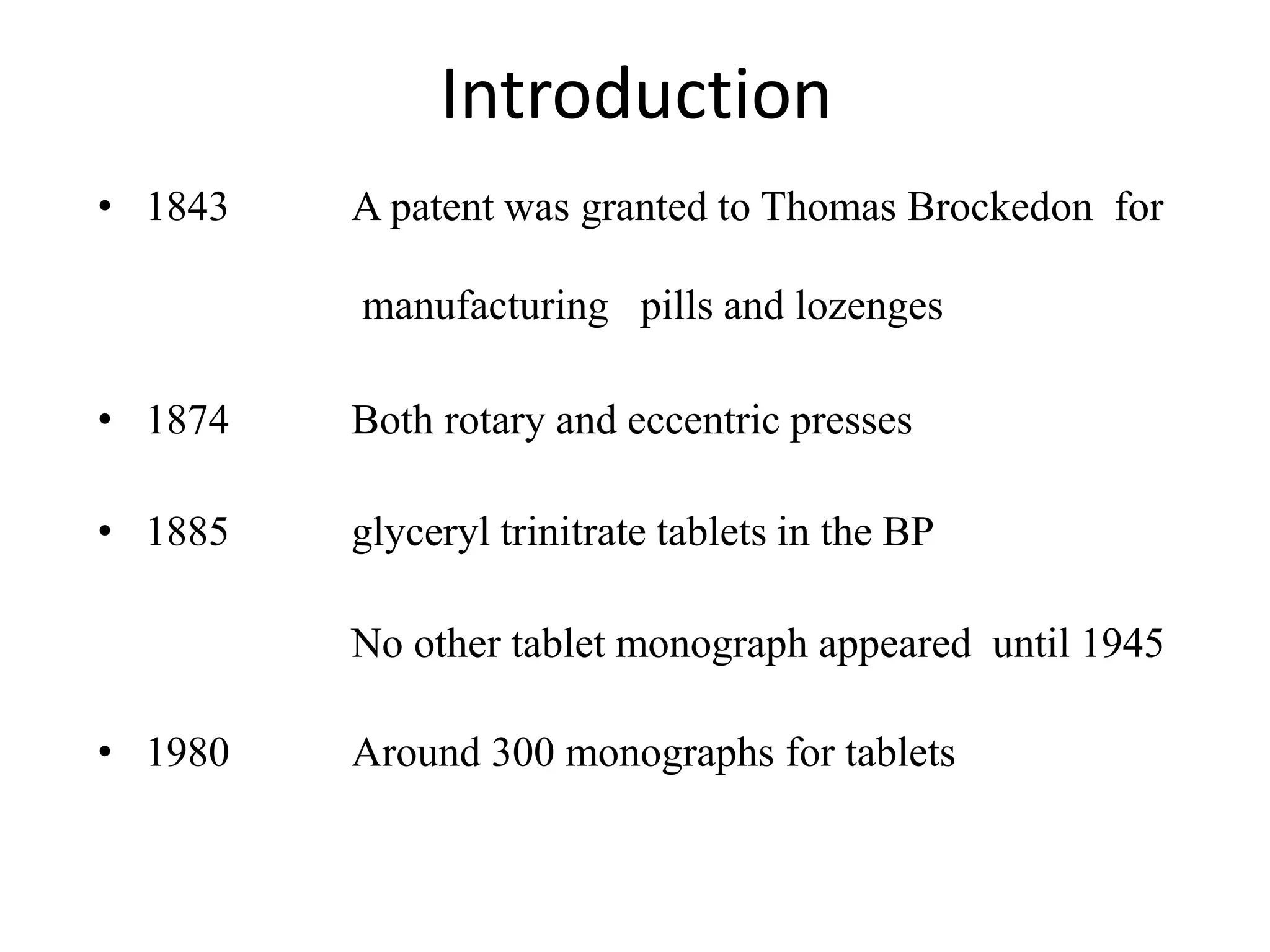

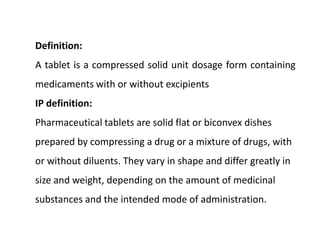

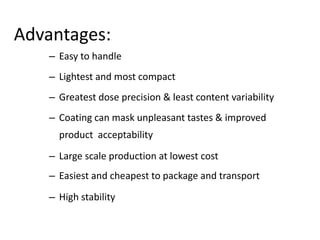

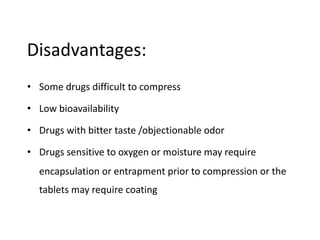

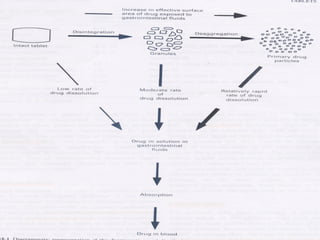

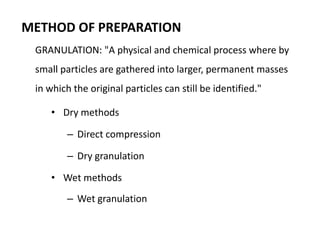

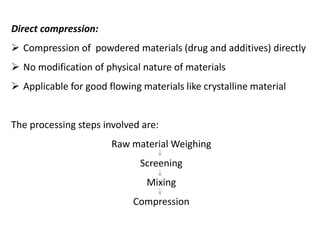

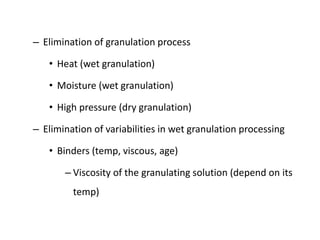

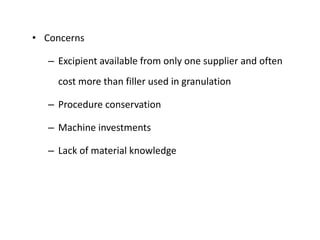

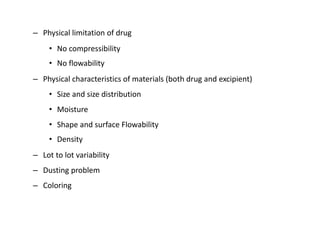

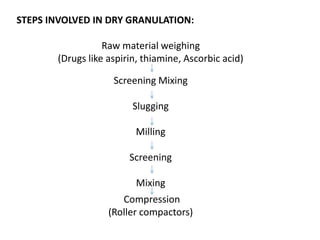

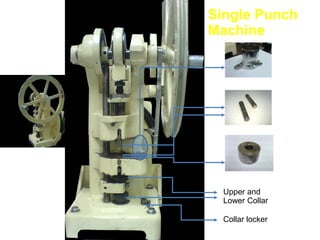

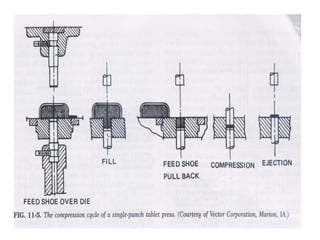

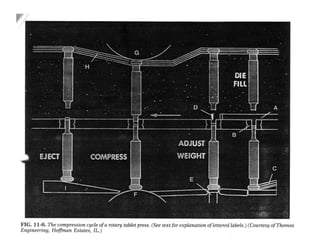

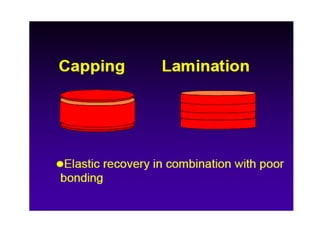

The document details the history and preparation methods of pharmaceutical tablets, including definitions, advantages, and disadvantages. It covers manufacturing techniques such as dry and wet granulation, as well as the components and functioning of tablet compression machines. Additionally, it addresses common processing problems in tablet production, providing insights into potential solutions.