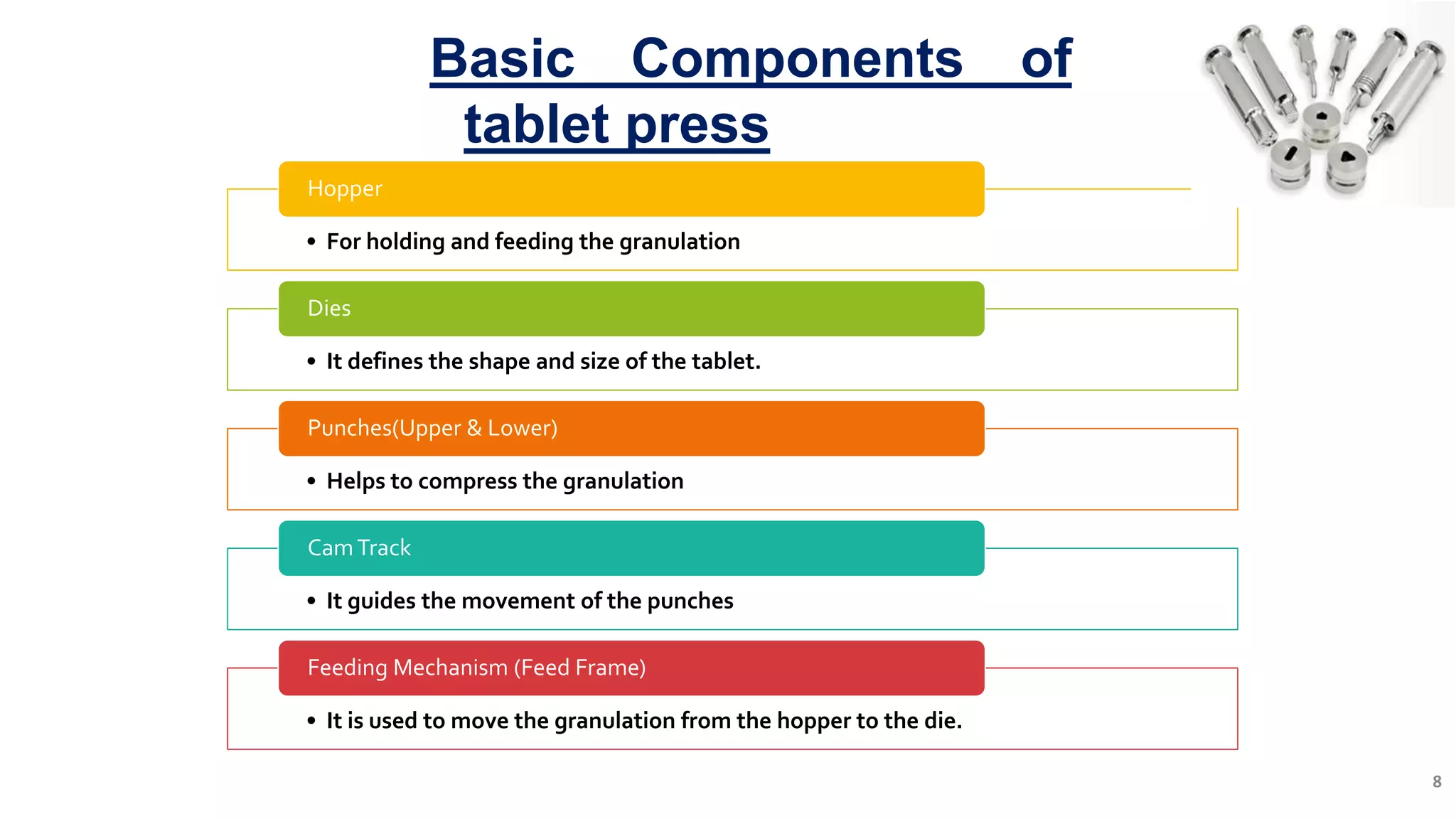

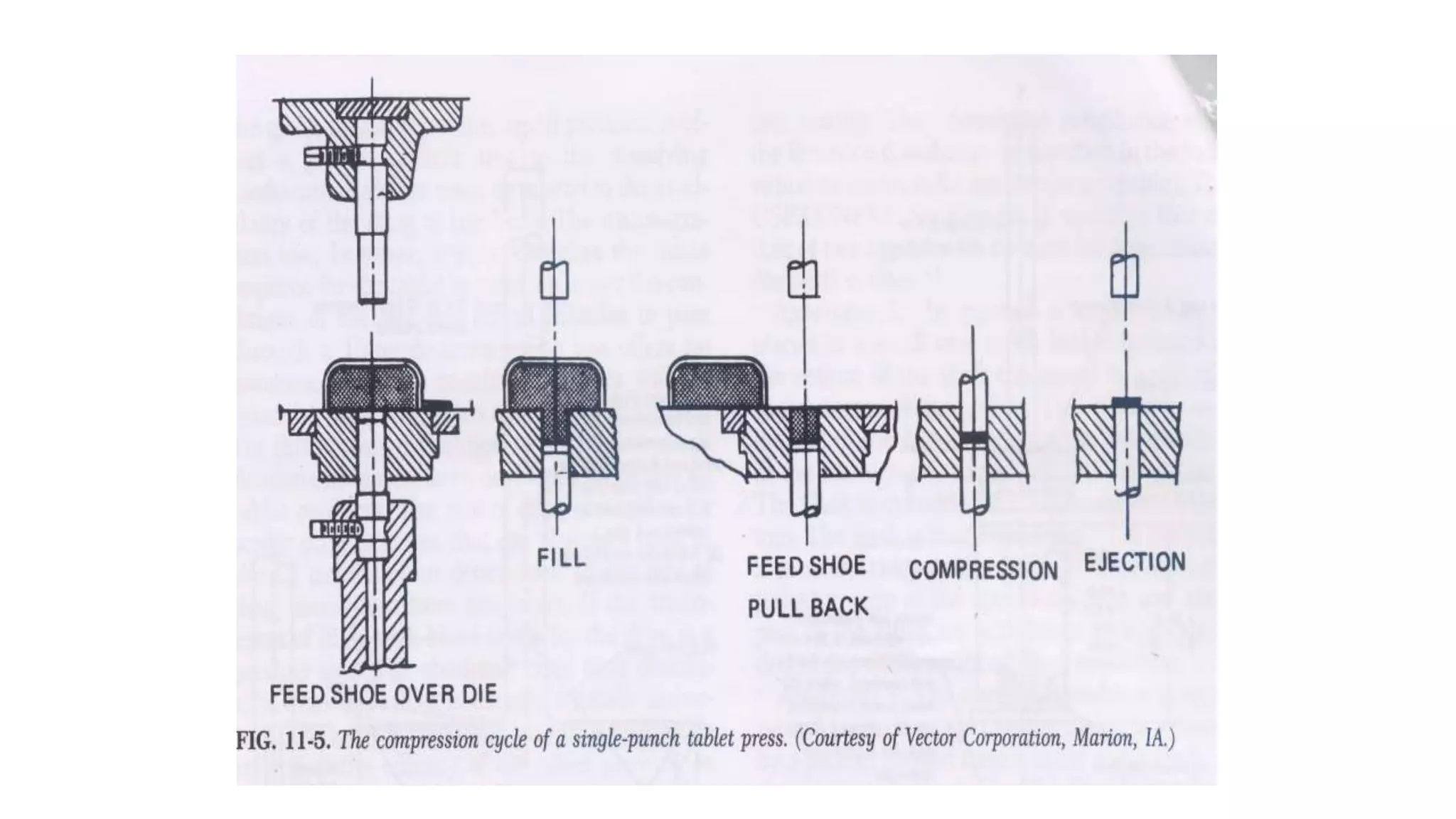

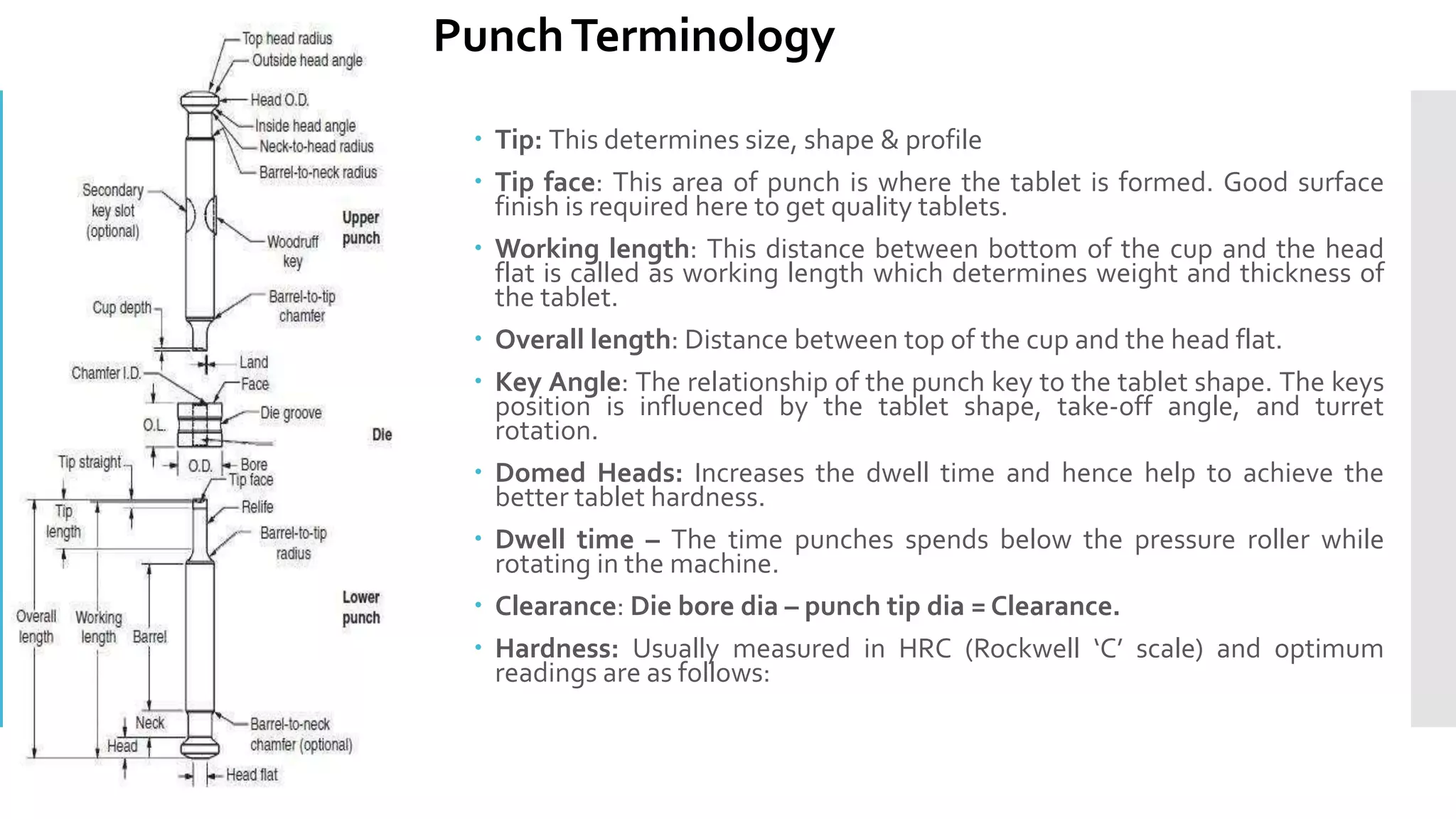

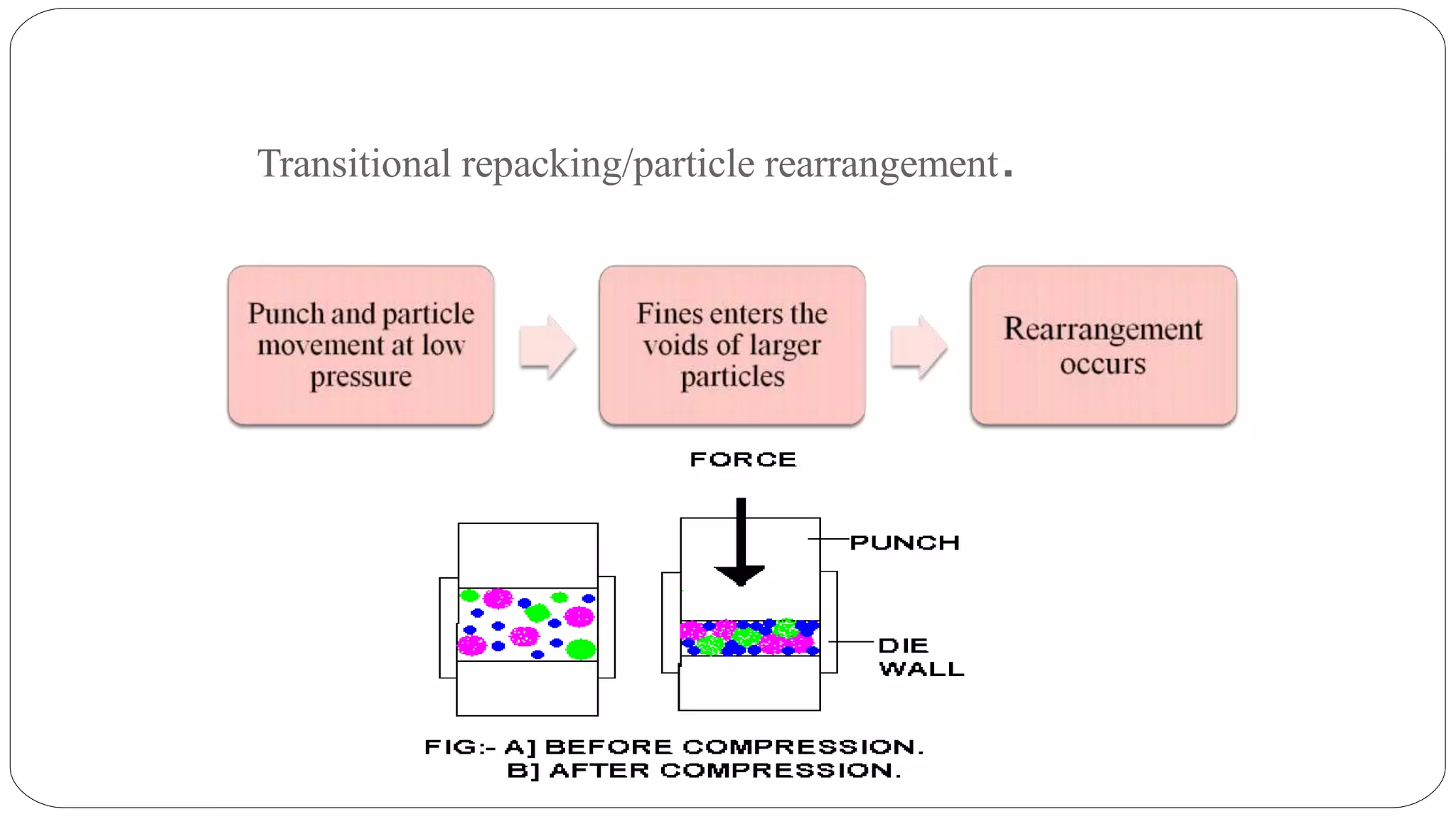

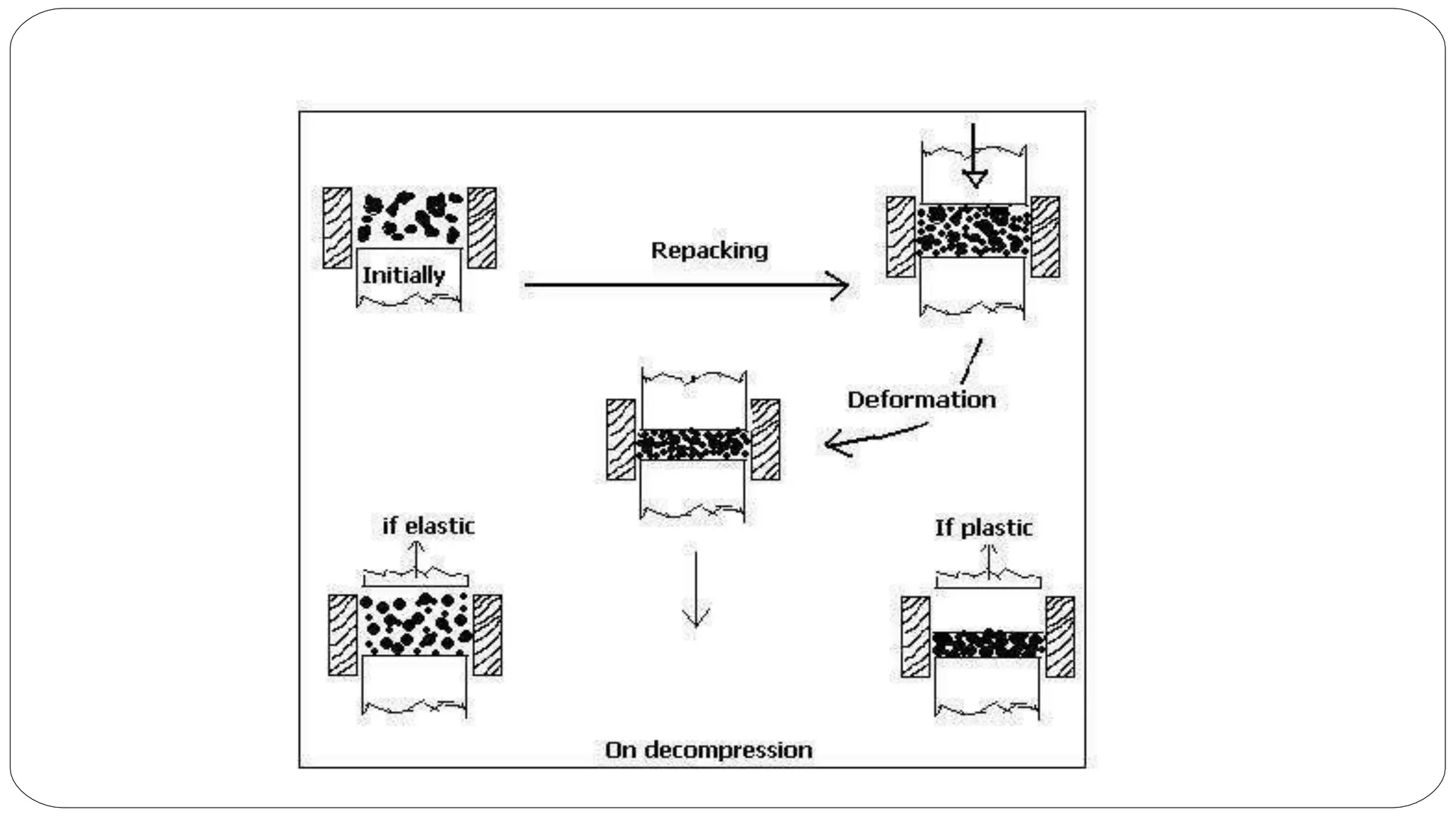

The document discusses various aspects of tablet compression. It begins by describing the basic components of a tablet press including the hopper, dies, punches, cam track, and feeding mechanism. It then covers different types of tablet presses and factors that affect the output. The document also discusses tooling configurations, terminology related to punches and dies, types of steel used, and classifications of tooling. Finally, it explains the stages of tablet compression including filling, metering, compression, and ejection as well as related post-compression equipment and the physics and forces involved in the compression process.

![Heckal’s plot

In heckel equation the decrease in porosity of powder bed as the

compression force increases is assumed to follow the following

equation:

Where, D= ρave / ρtrue

ρave = the average density of the powder bed.

ρtrue = true density of the powder.

(1-D) = porosity.

K = constant.

Upon integration:

In heckel plot we draw ln[1/1-D] as a function of compression

pressure P.](https://image.slidesharecdn.com/tabletcompressionbyvdr-200109101016/75/Tablet-compression-Compression-Consolidation-Compaction-61-2048.jpg)