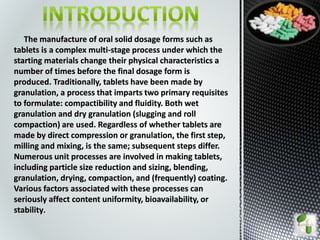

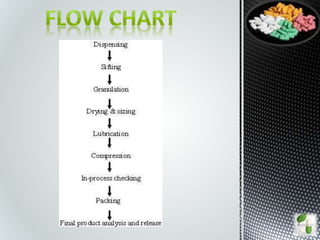

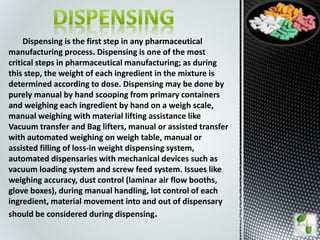

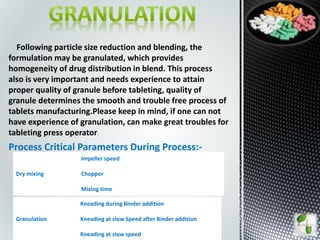

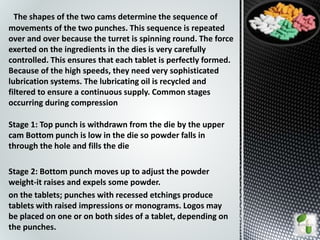

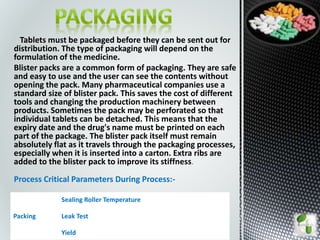

The document summarizes the key steps involved in manufacturing oral solid dosage forms like tablets. It involves size reduction of raw materials, blending, granulation, drying, lubrication, compression into tablets, coating if needed, and final packaging. Precise control of critical process parameters is required at each stage to ensure quality, bioavailability and stability of the final tablets. Granulation is an important step for uniform distribution of drugs in the blend and influences tableting process. Drying is also critical to control residual moisture. Compression forms the tablets and critical parameters like hardness and disintegration time need to be monitored.