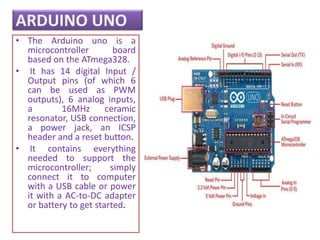

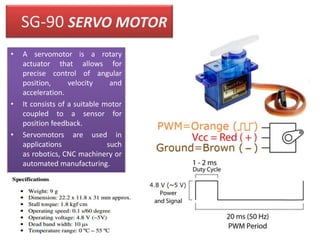

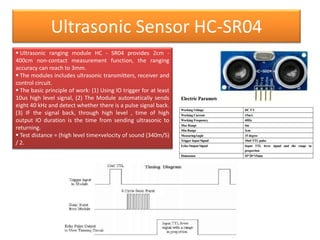

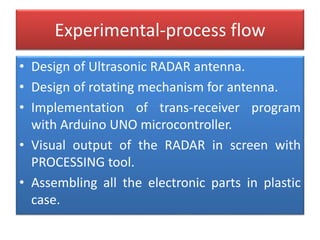

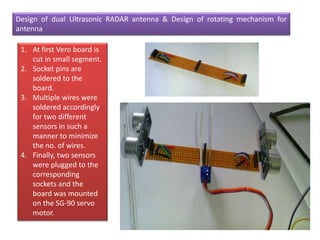

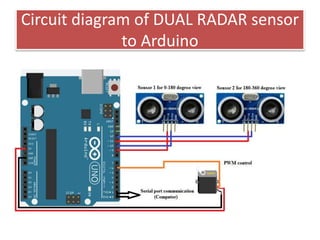

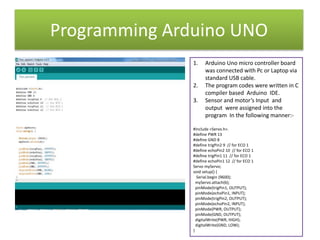

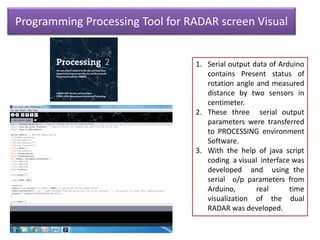

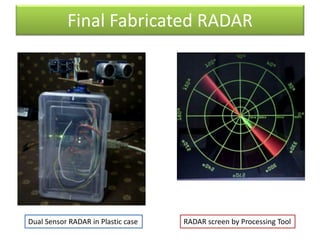

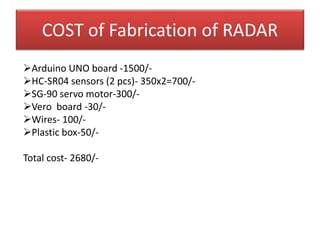

This document describes the design and fabrication of a dual ultrasound-based pulse wave radar system with 360-degree vision. Key components include an Arduino Uno microcontroller, two HC-SR04 ultrasonic sensors, an SG-90 servo motor, and a Processing software interface. The system was designed to rotate the ultrasonic sensors using the servo motor to enable 360-degree distance measurement. Programming was done to control the sensors, motor and process sensor data for visual output on the Processing interface. The total cost of components for fabricating the prototype radar system was approximately 2680 Indian rupees.