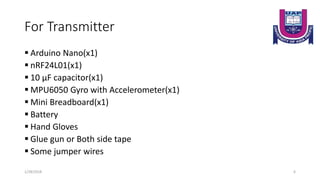

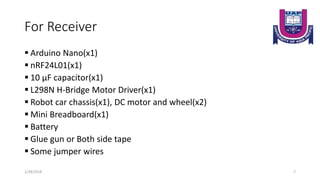

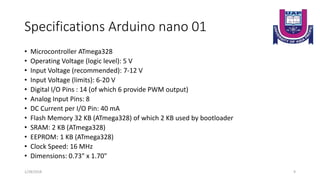

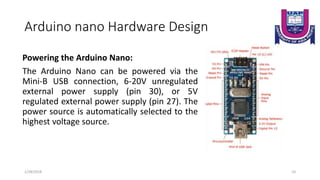

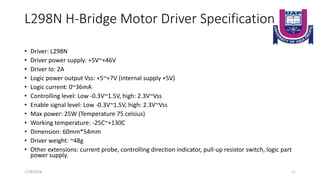

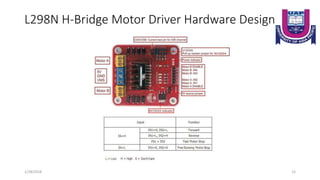

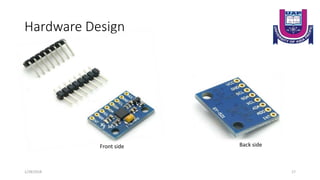

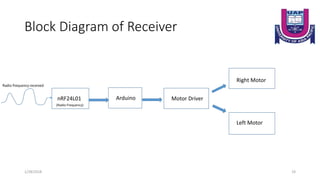

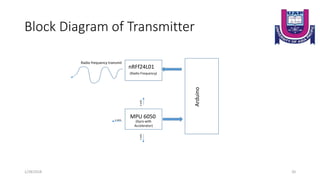

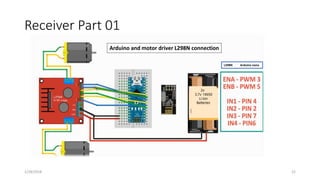

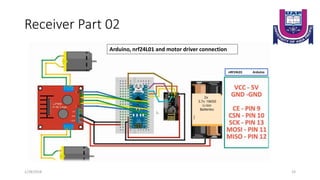

The document describes a hand gesture controlled robot that uses a hand glove with an MPU-6050 gyroscope/accelerometer sensor and Arduino board to wirelessly control a receiving robot car chassis. The transmitter sends gesture movement data via nRF24L01 modules to the receiver Arduino, which uses the data and an L298N motor driver to control the car's two DC motors. Potential applications include remote control of devices, industrial equipment, military robotics, medical procedures, and construction.