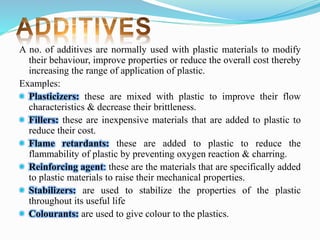

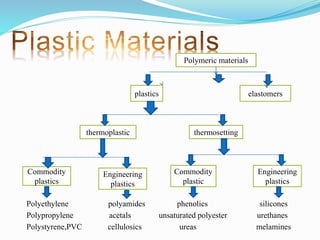

Plastics are polymers formed through polymerization reactions that join small organic molecules into long chains. Monomers are the basic building blocks that undergo polymerization to create polymers. There are two main types of polymerization: addition polymerization and condensation polymerization. Addition polymerization involves breaking carbon double bonds in monomers to form chains, producing thermoplastics. Condensation polymerization reacts two different organic molecules to form plastic molecules and byproducts. A variety of additives can be mixed with plastics to modify properties, improve performance, or reduce costs.