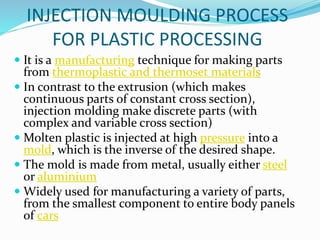

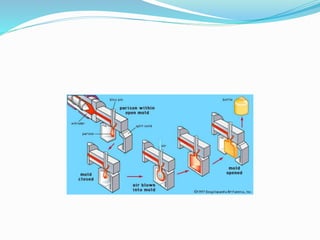

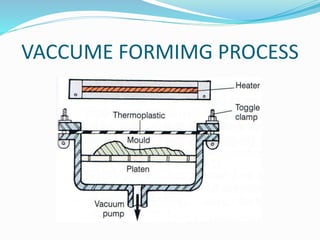

The document is a PowerPoint presentation on plastic molding processes, detailing injection molding, blow molding, and thermoforming techniques. It describes the injection molding process for creating complex parts from thermoplastic materials, the blow molding technique for producing hollow parts using parison, and the thermoforming process that forms plastic sheets under temperature and pressure. The presentation also covers machine components, materials used, and various applications for these plastic processing methods.