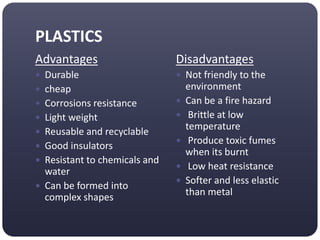

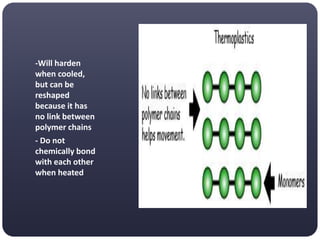

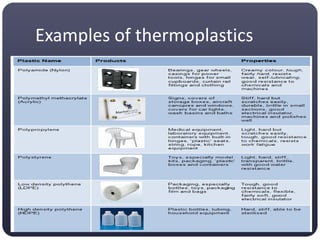

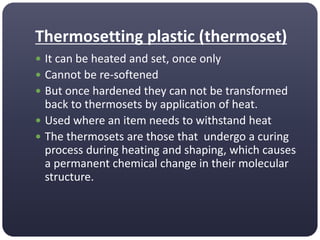

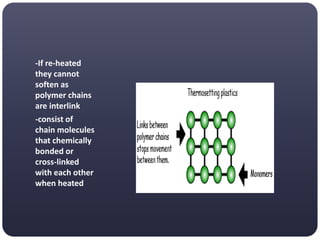

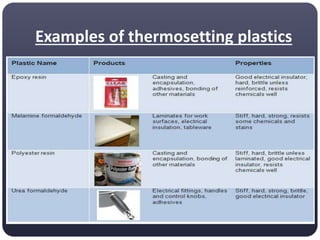

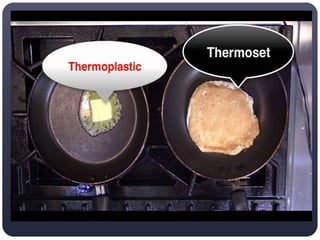

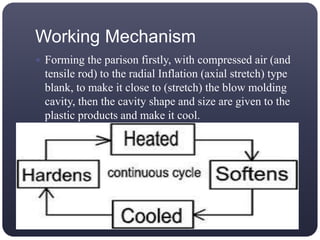

Plastics are synthetic organic materials that can be molded under heat and pressure into shapes that are retained when the heat and pressure are removed. There are two main types of plastics: thermoplastics, which can be softened and reshaped by reheating, and thermosetting plastics, which undergo a chemical change when heated and hardened that prevents them from being re-softened. Plastic forming involves shaping plastics using molds or frames, with common processes including injection molding, extrusion molding, blow molding, vacuum forming, compression molding, and rotational molding.