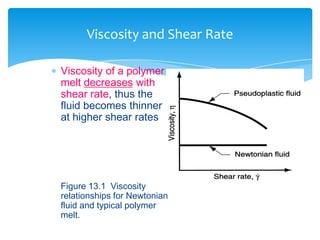

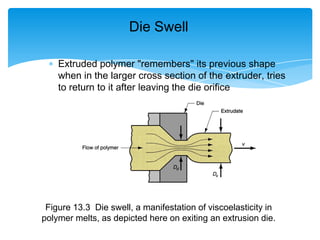

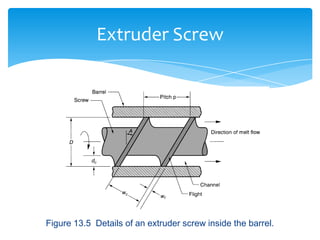

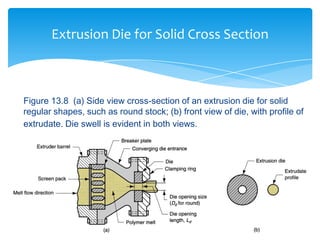

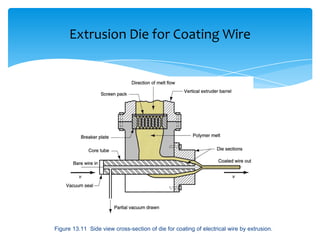

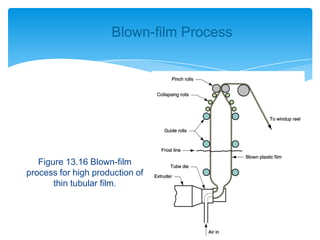

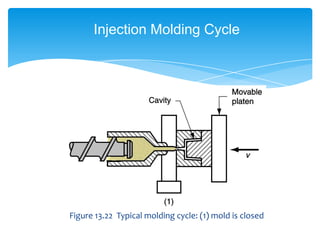

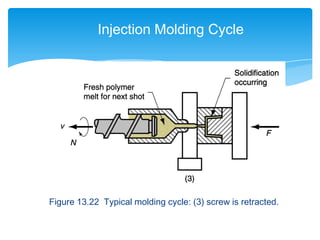

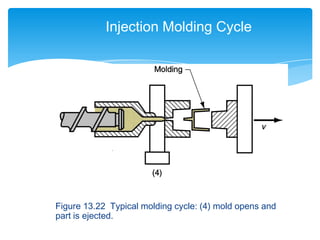

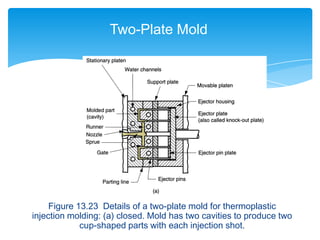

This document discusses various plastic shaping processes. It begins by describing extrusion, which uses compression to force polymer melts through a die to produce continuous profiles. Extruders consist of a barrel and screw. Sheet and film can be produced via slit-die or blown film extrusion. Injection molding injects molten plastic into a mold cavity at high pressure to form discrete parts. It involves an injection unit and clamping unit. The mold contains the cavity and features to distribute plastic and eject parts.