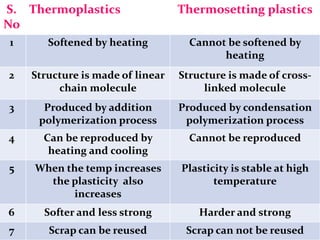

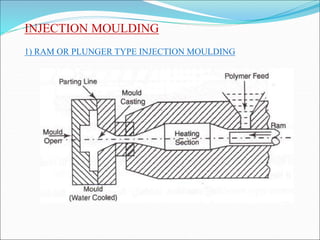

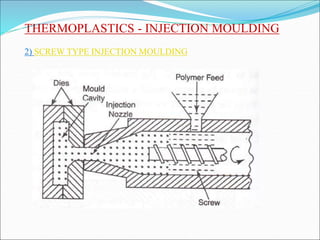

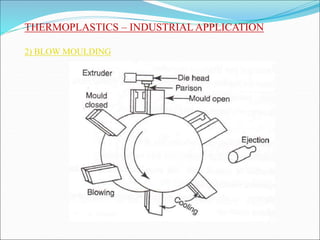

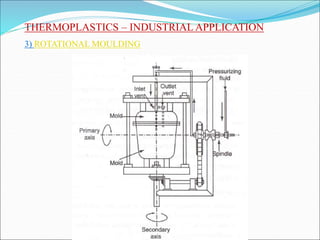

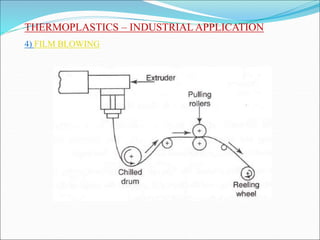

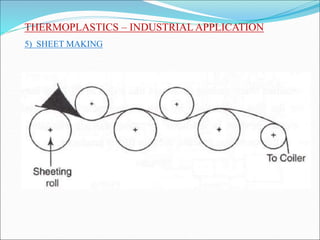

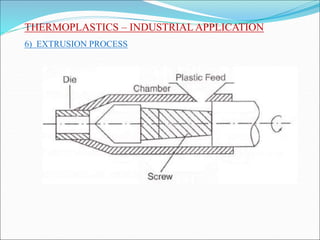

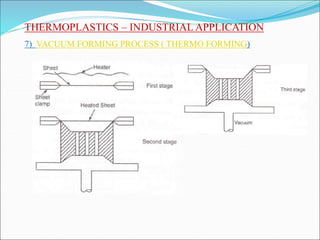

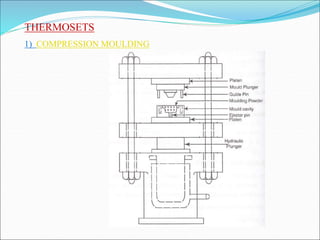

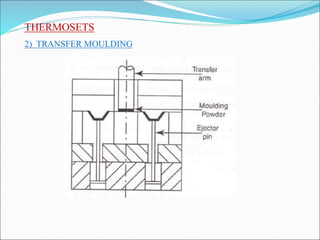

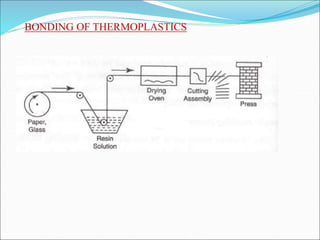

The document discusses various topics related to plastics manufacturing including types of plastics, polymerization processes, properties of thermoplastics and thermosets, and common shaping processes. It describes how thermoplastics can be softened by heat and reshaped, while thermosets undergo a chemical change and maintain their shape after heating. Common industrial manufacturing techniques for plastics are also summarized, such as injection molding, blow molding, rotational molding, extrusion, and thermoforming.