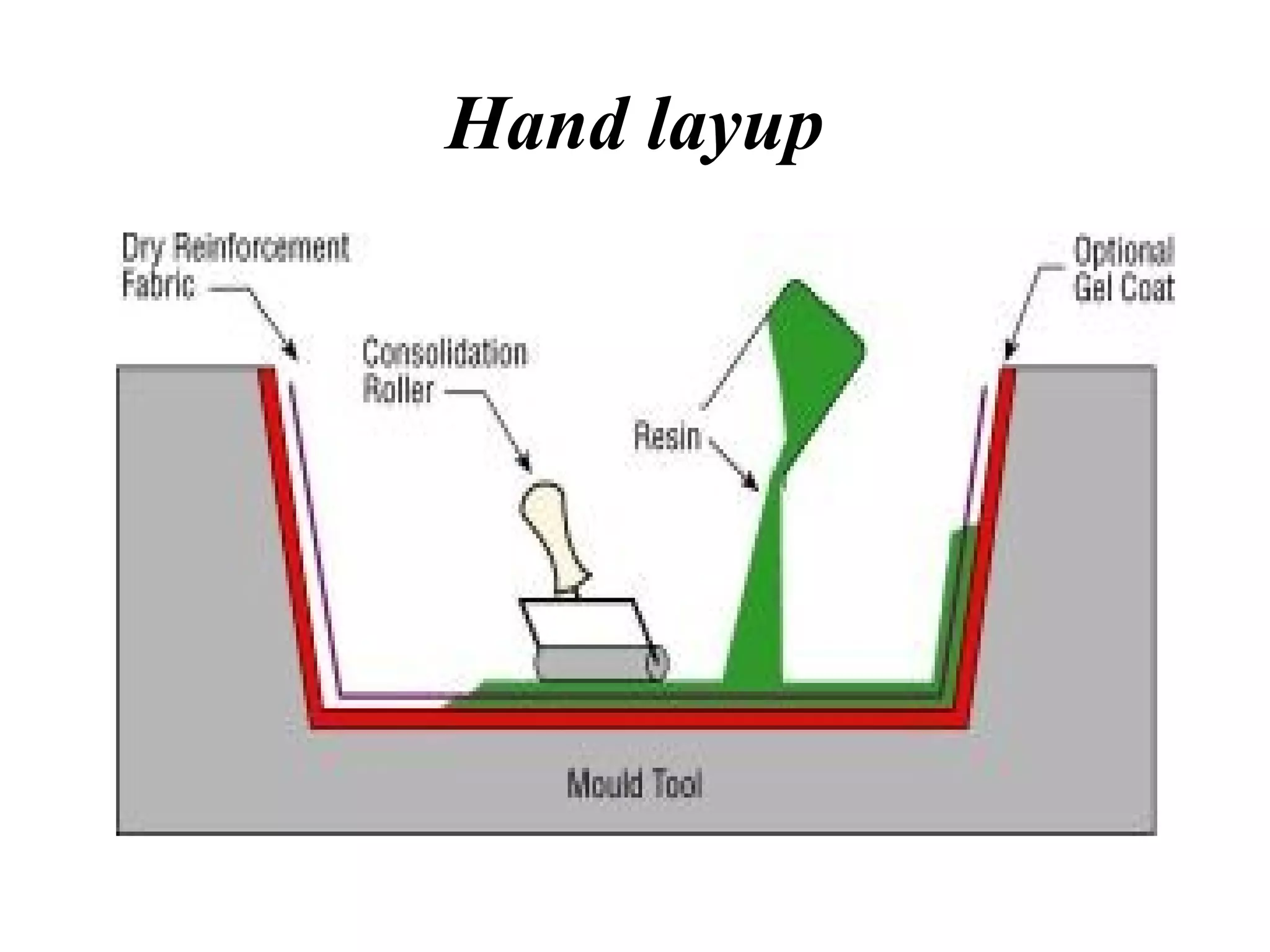

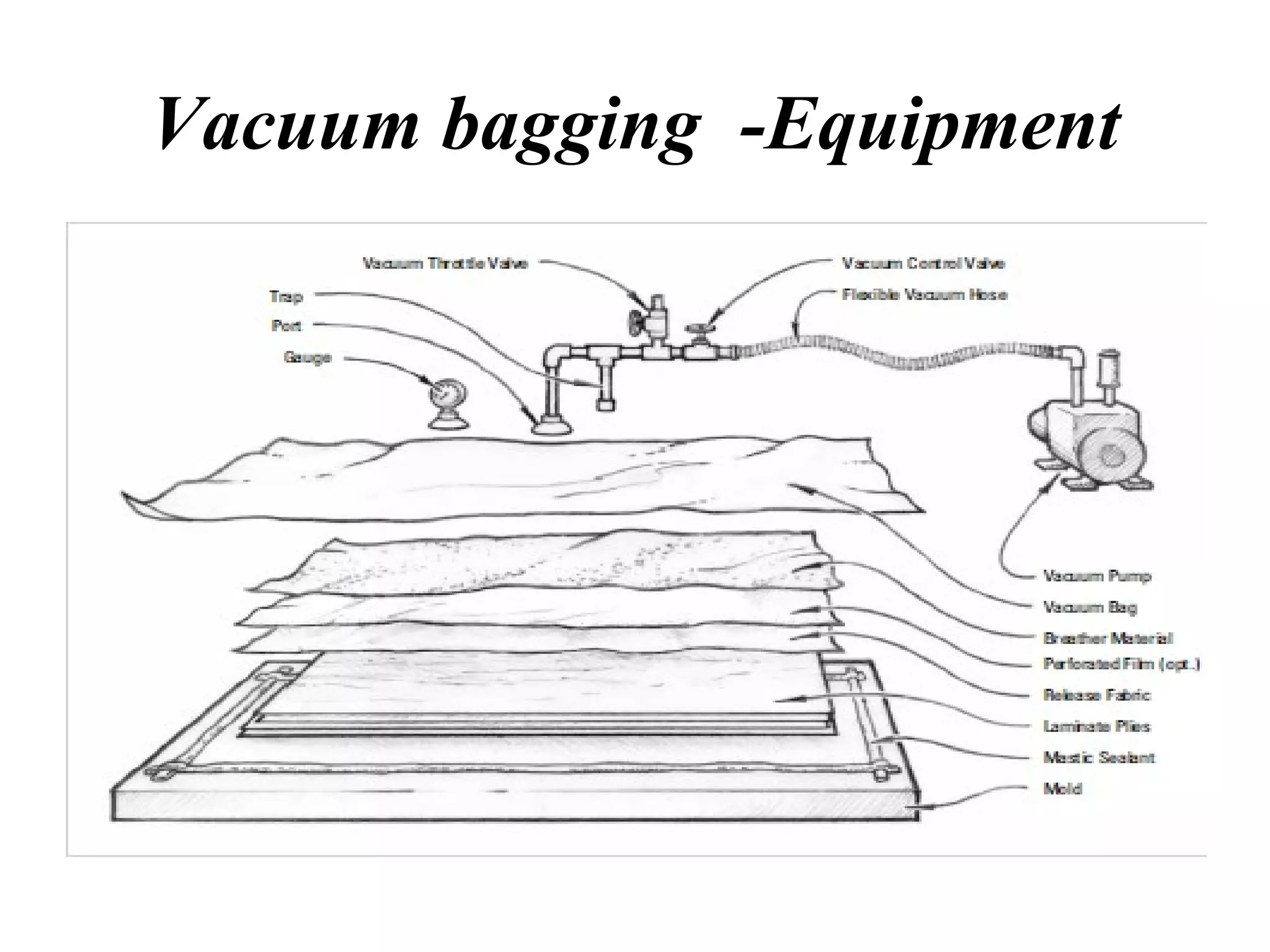

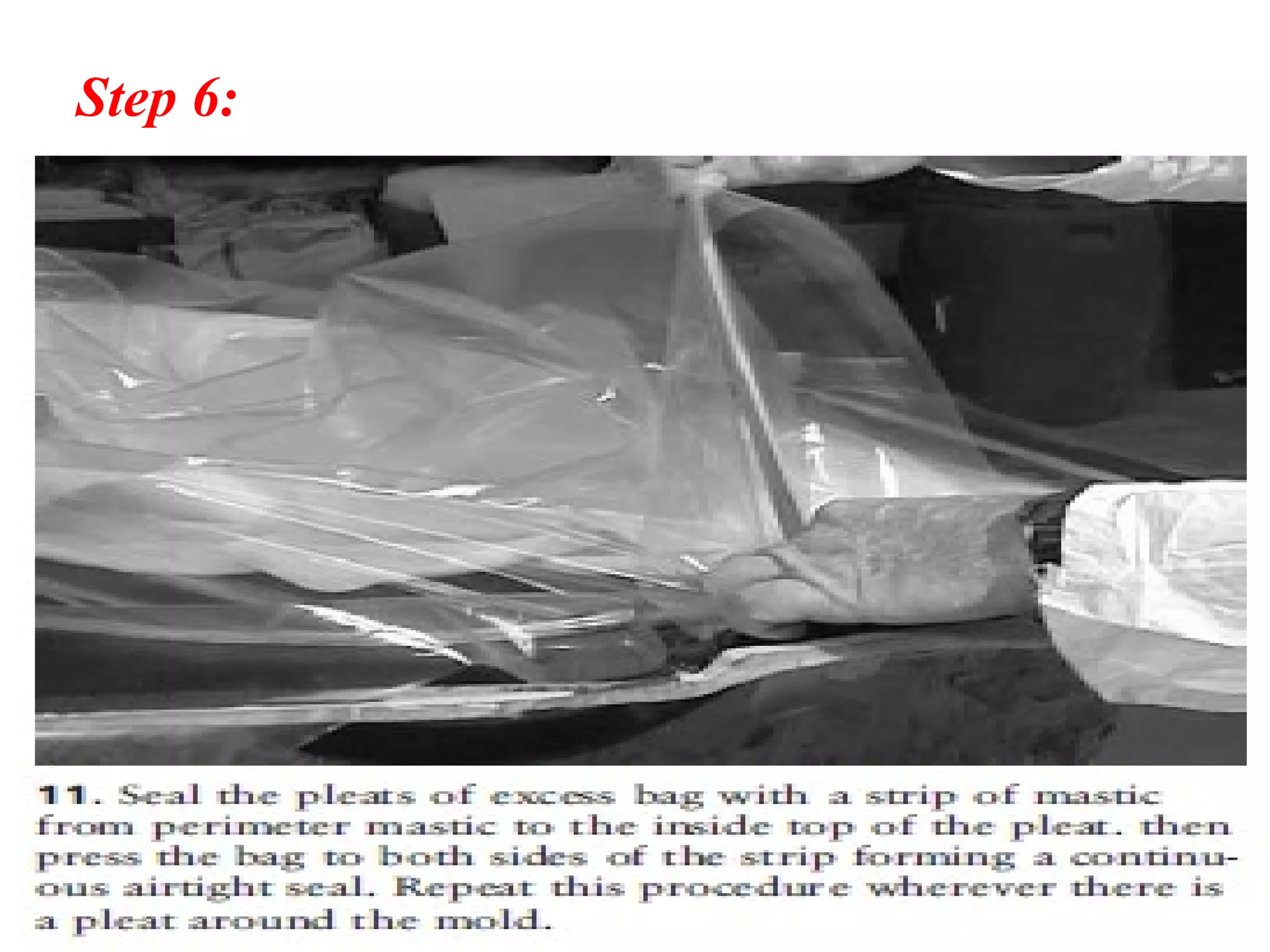

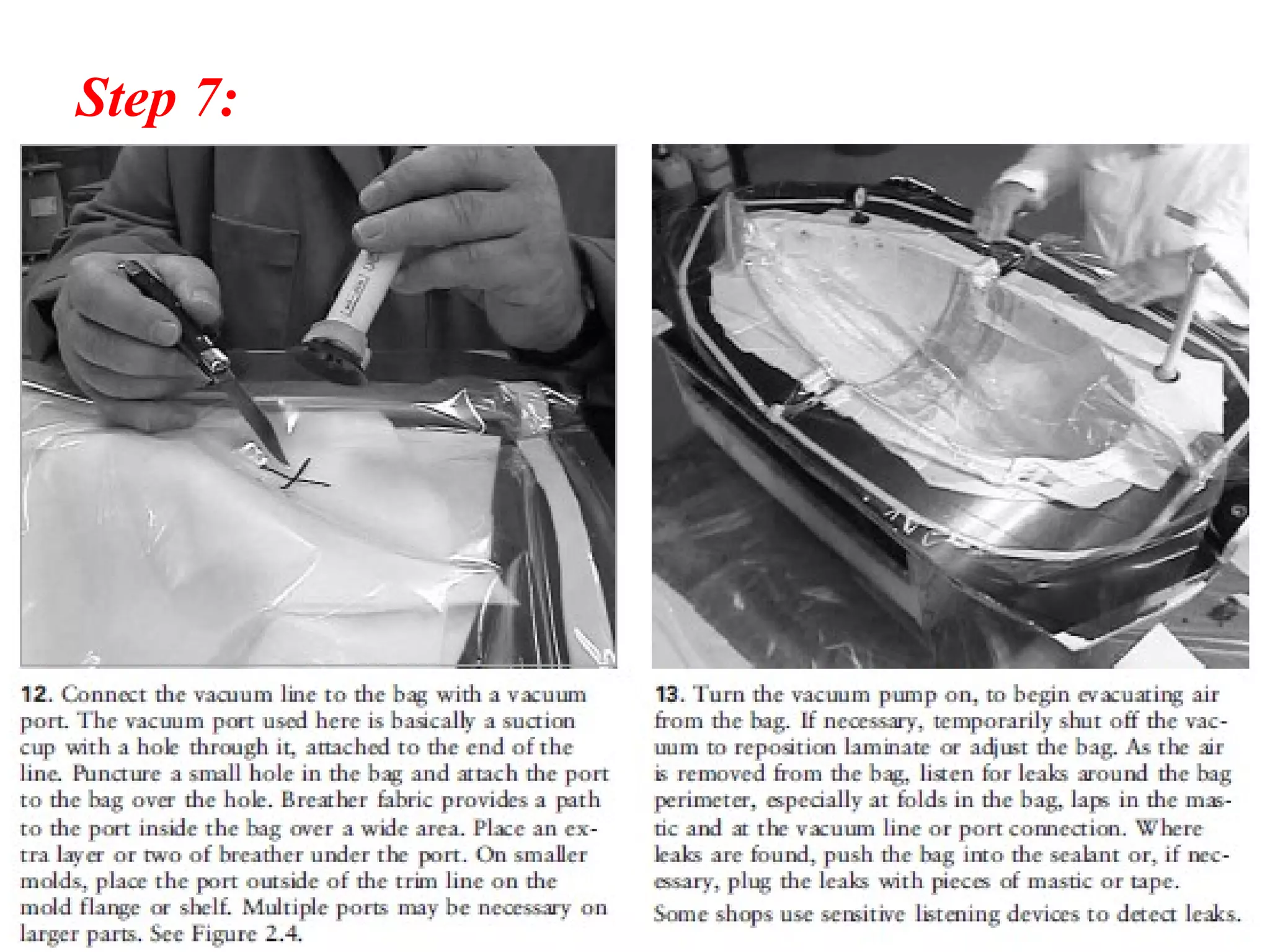

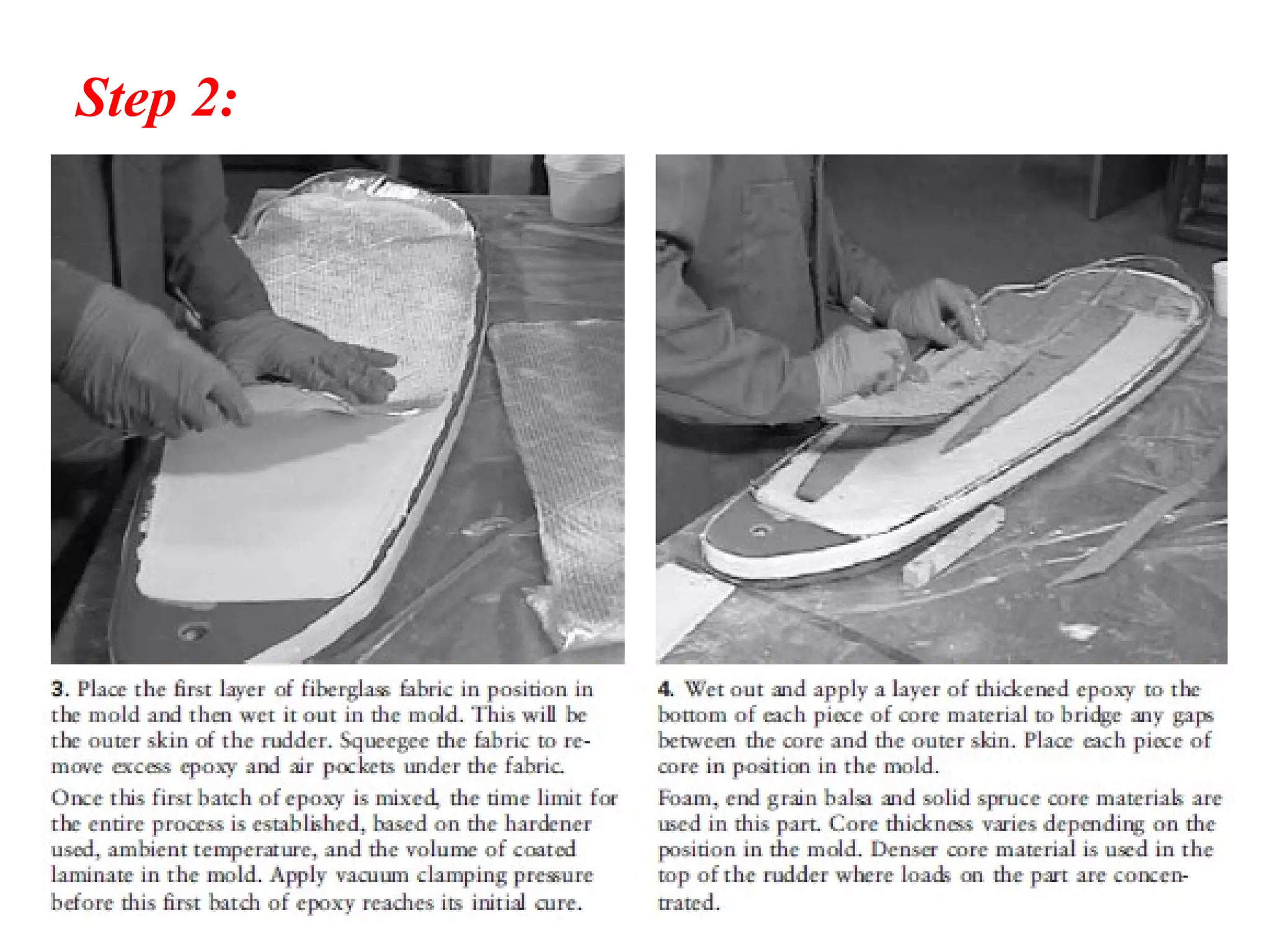

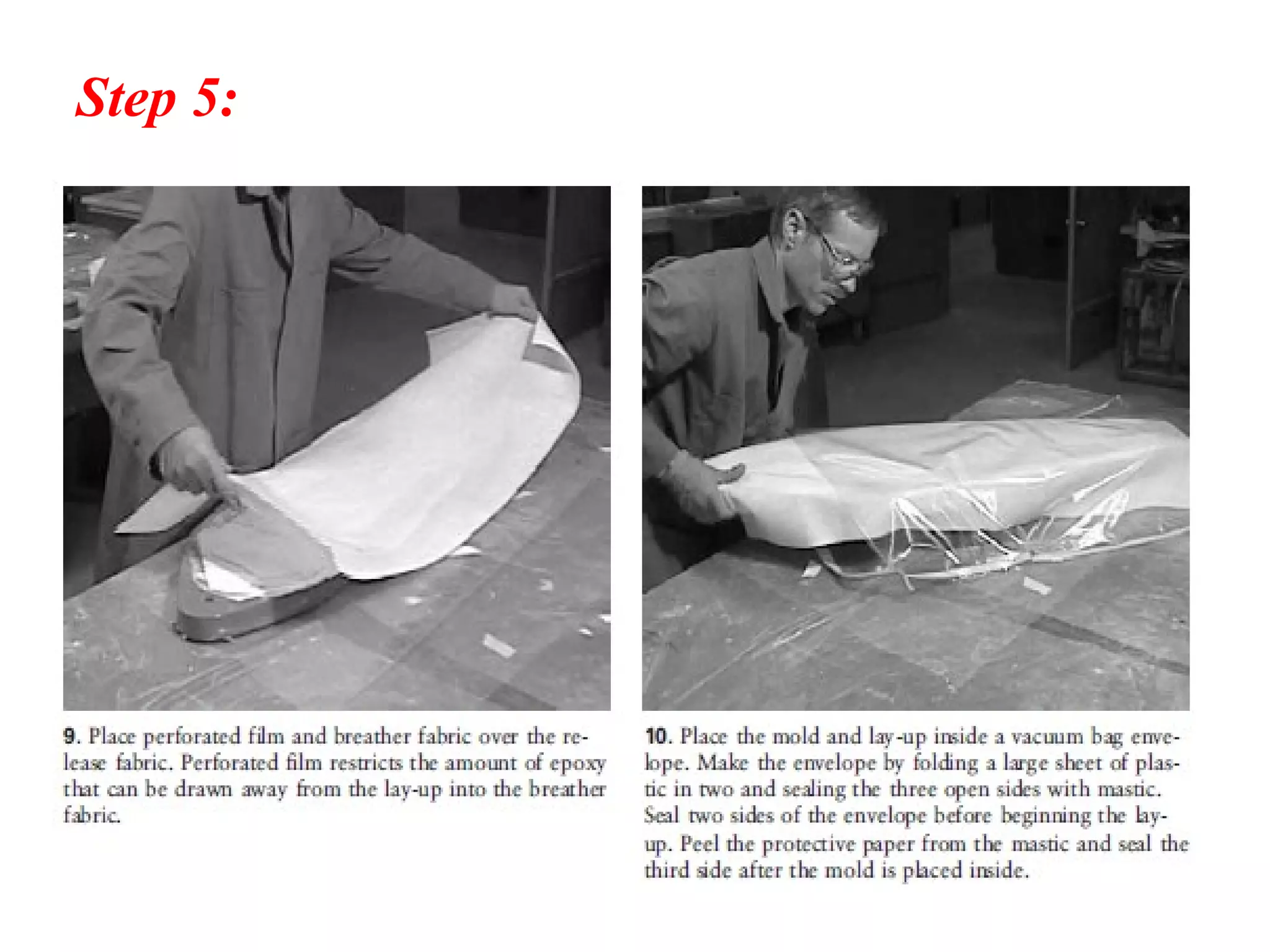

Vacuum bag molding is an open mold technique used for thermoset composites involving hand layup and vacuum bagging. Vacuum bagging uses a vacuum bag to apply even pressure over composite materials to consolidate them. It involves placing release fabrics, breather materials, and vacuum bags over molds with resin-coated components. Applying vacuum pressure draws air out and uses atmospheric pressure to hold components in place until the resin cures.