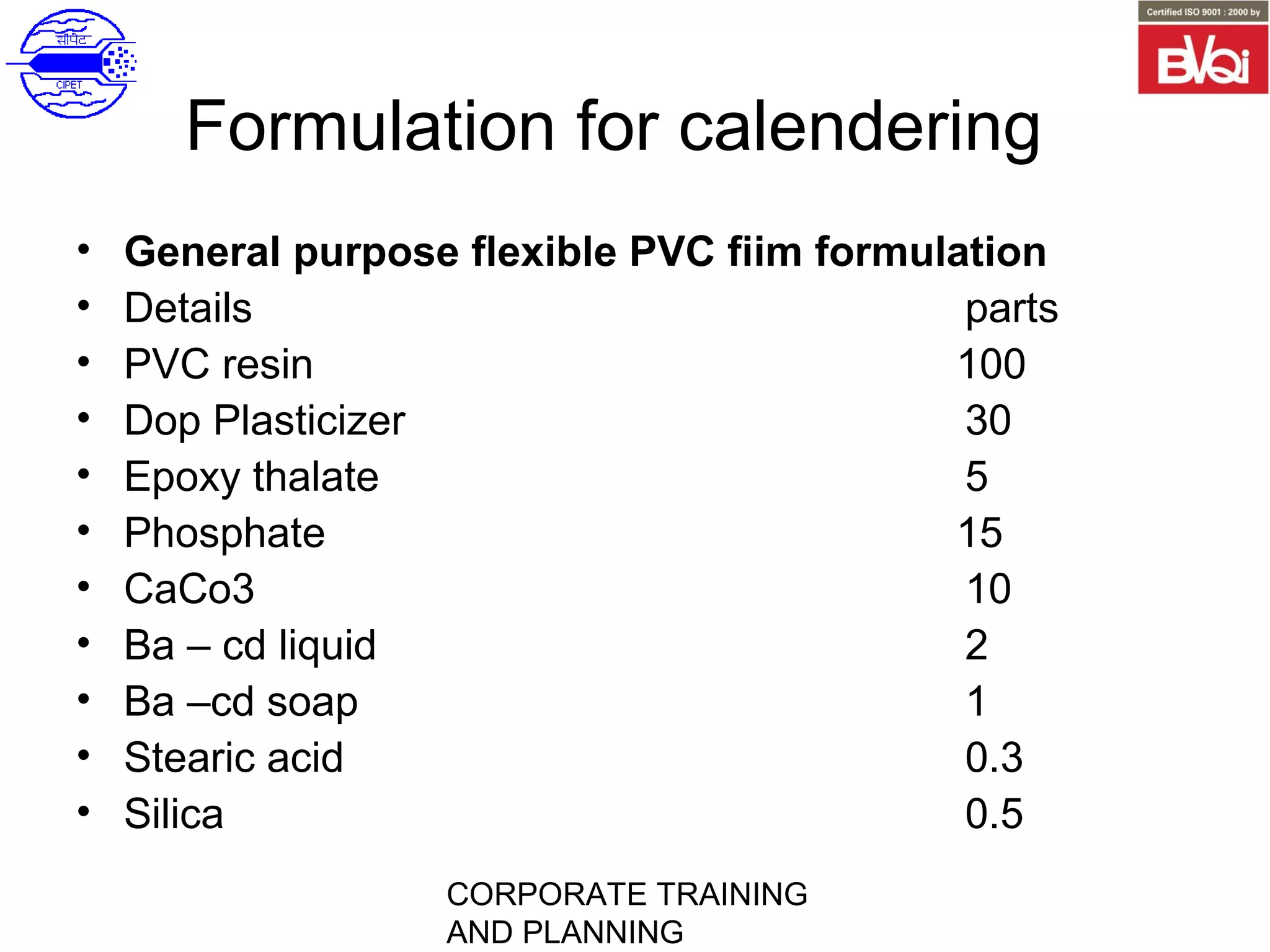

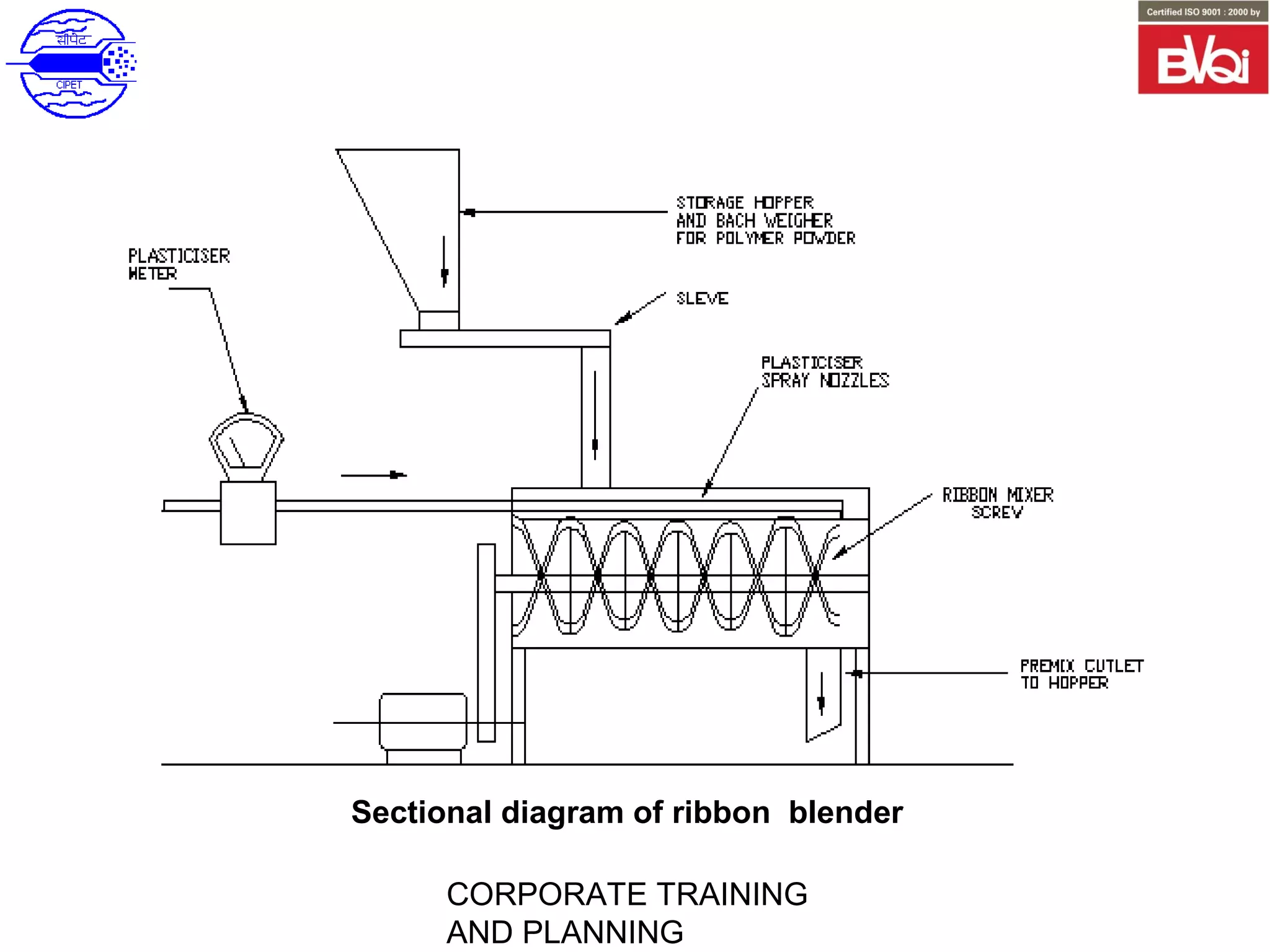

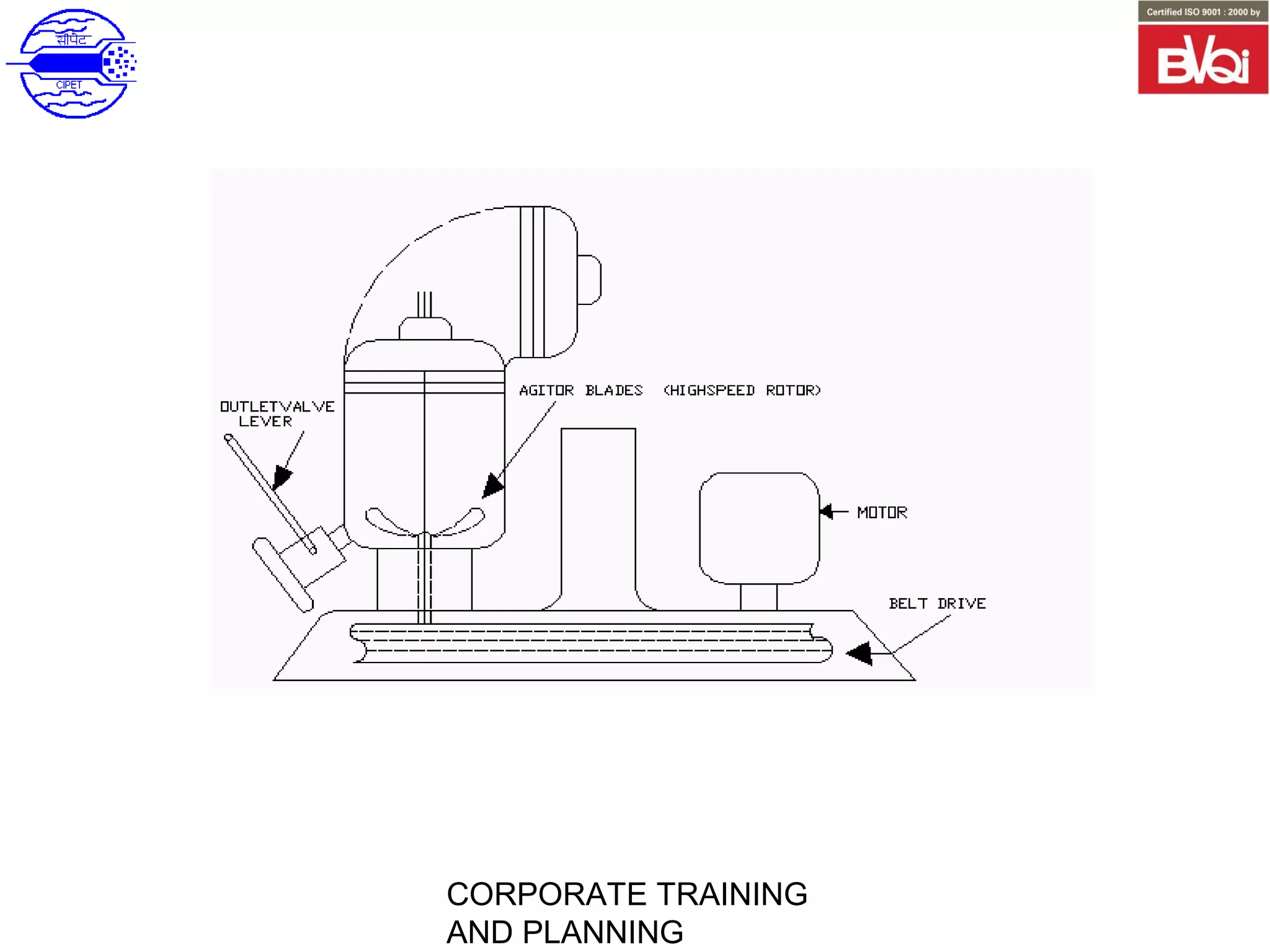

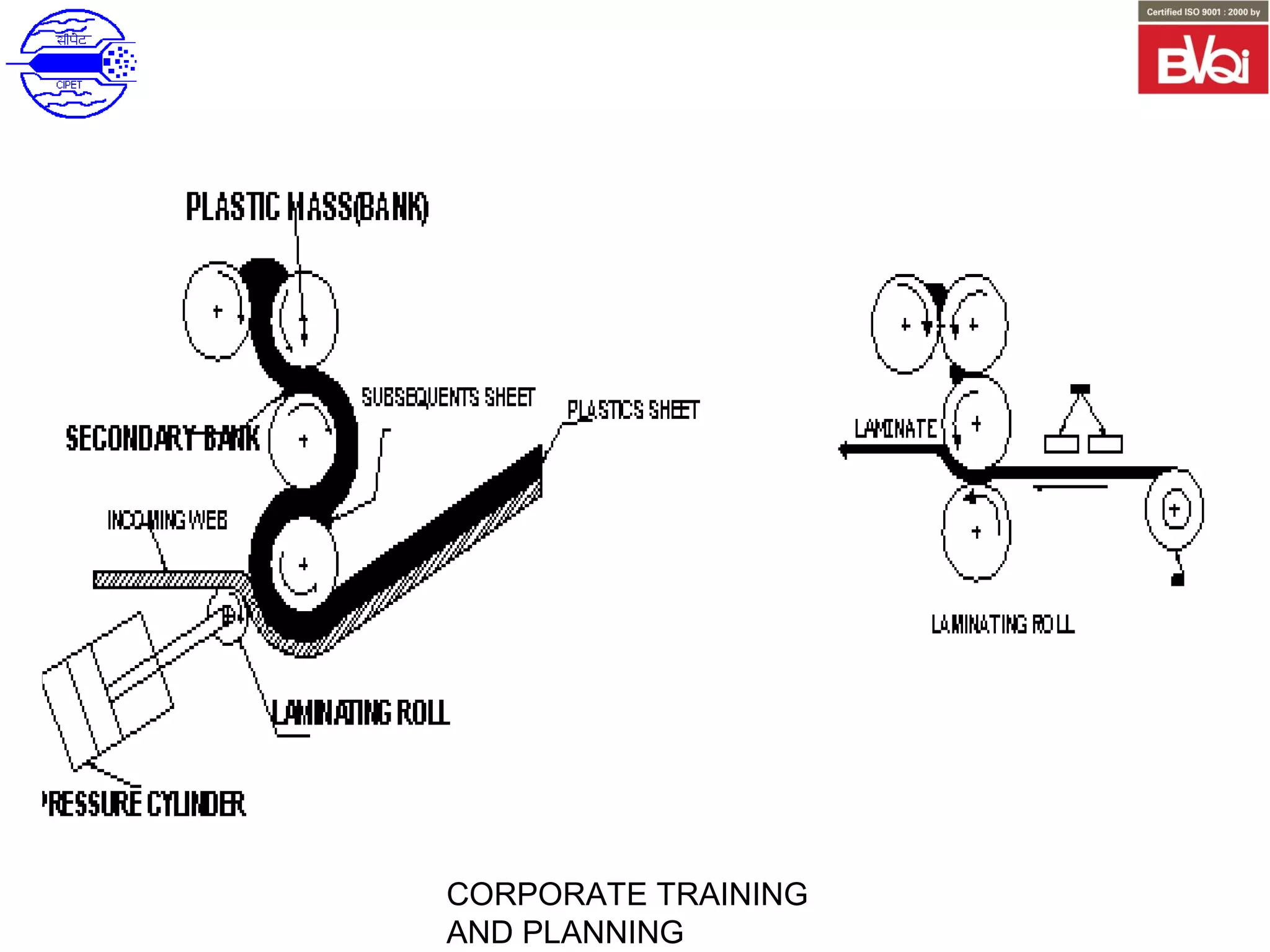

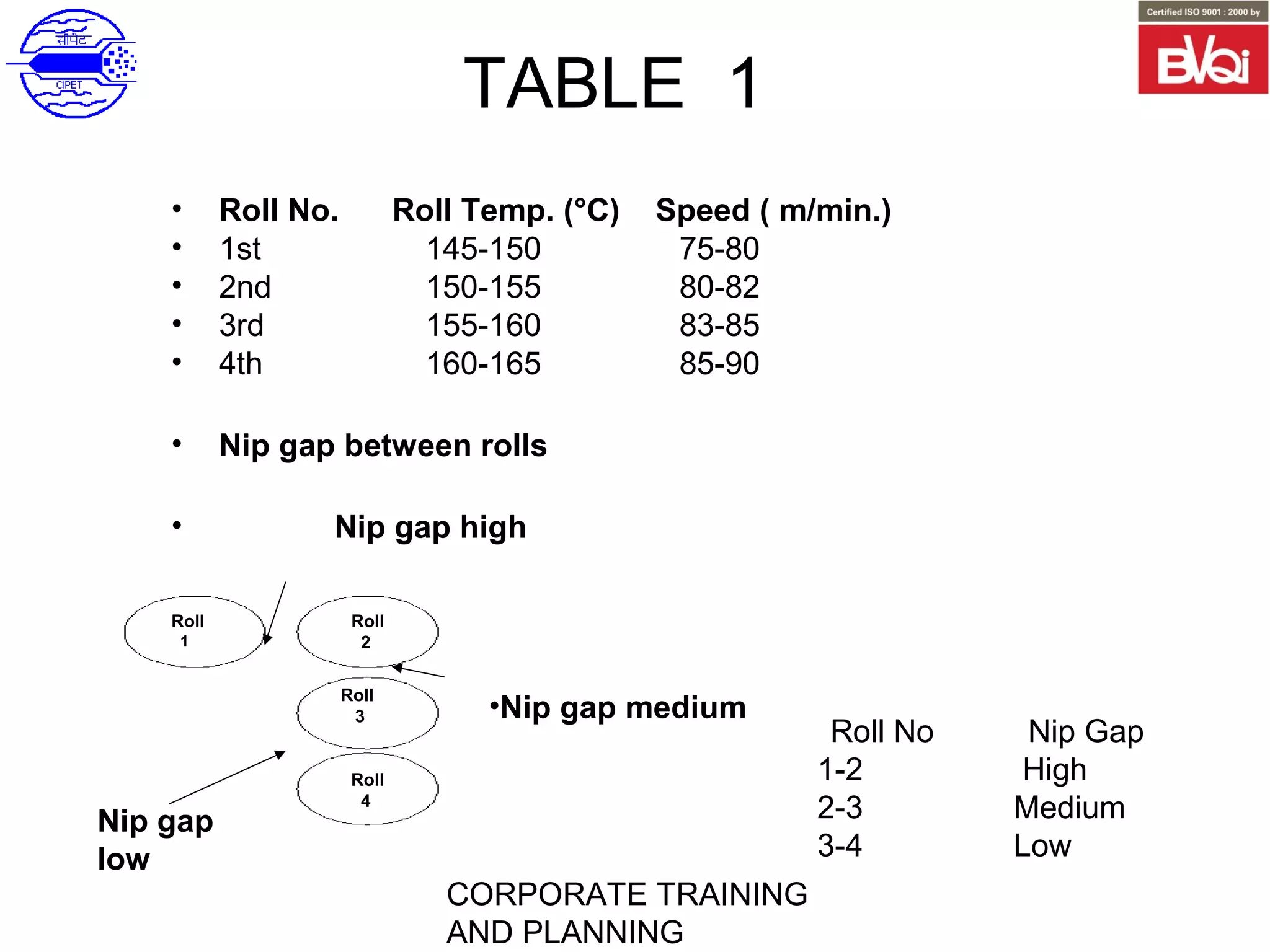

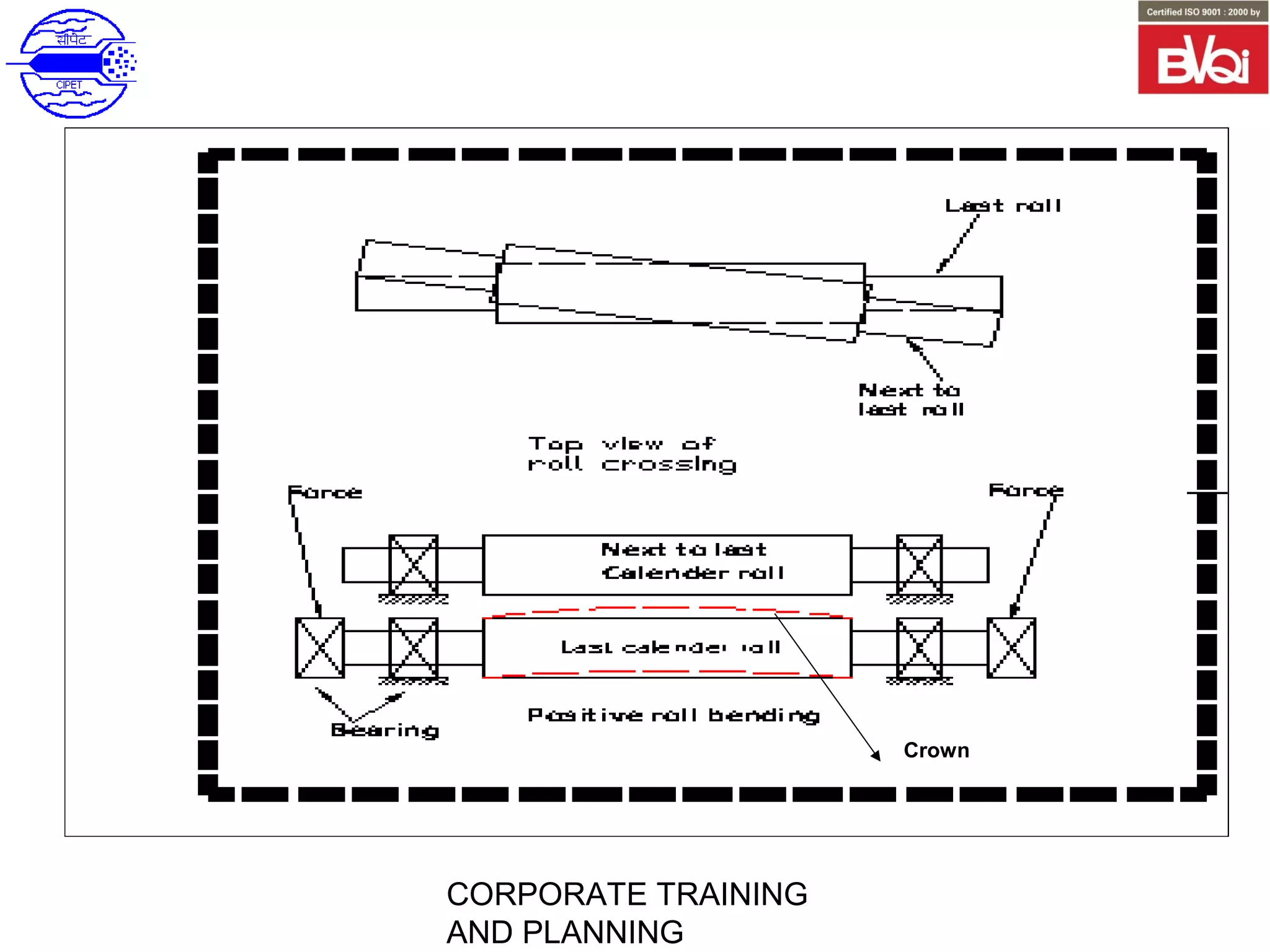

The document discusses the calendaring process for producing plastic sheets. It involves passing a plastic melt between heated counter-rotating rolls to form a continuous film or sheet. Key steps include compounding the plastic with additives, fluxing the compound, feeding it to heated calendar rolls, and winding the cooled sheet. Parameters like roll temperature, speed, and nip gap are controlled. Common applications of calendared sheets include packaging, medical products, flooring, and automotive parts.