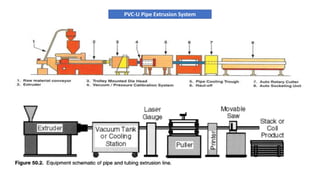

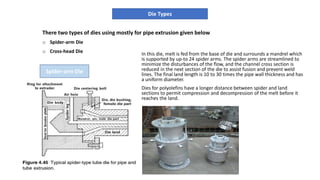

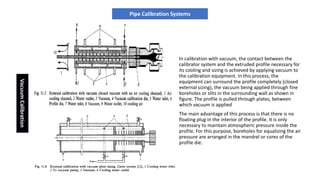

The document summarizes the key components and processes involved in pipe extrusion lines. Molten plastic is extruded through a die into the shape of a pipe. It is then calibrated to finalize dimensions before cooling. There are different types of dies, including spider-arm and cross-head dies, as well as calibration methods like using water-cooled mandrels, vacuum, or pressure to control the pipe thickness and dimensions. After calibration and cooling, haul-off units pull the pipe for cutting to final lengths.