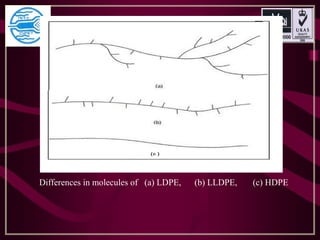

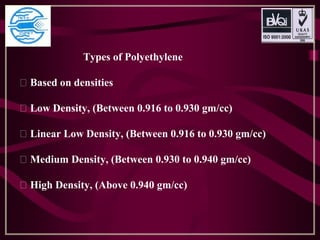

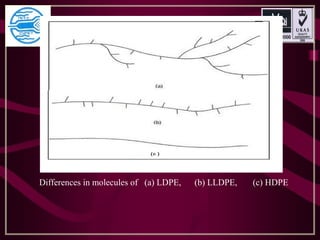

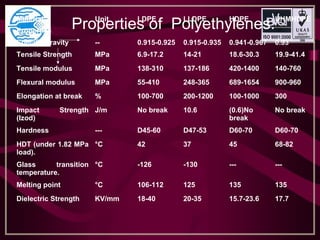

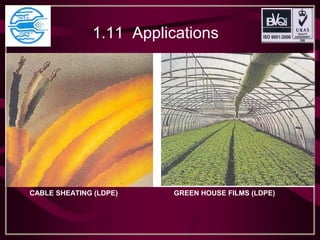

The document discusses the properties, structure, processing, and applications of polyethylene. It describes the different types and grades of polyethylene based on density, including low density polyethylene, linear low density polyethylene, medium density polyethylene, and high density polyethylene. It covers basic properties like melt flow index and density. It also discusses additives, processing techniques like injection molding and blow molding, and common applications like blow molded containers, pipes, films, and sheeting.