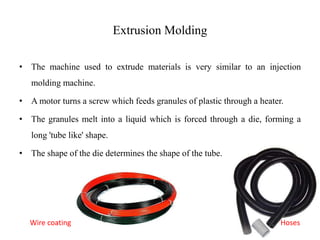

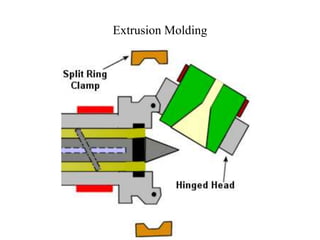

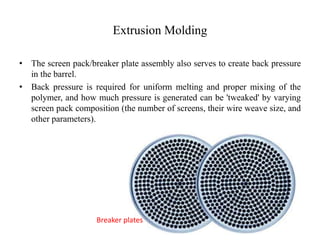

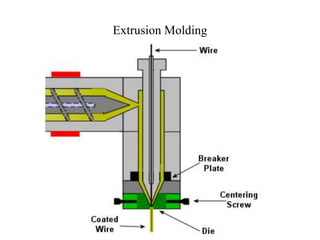

Extrusion molding is a process that uses heat and pressure to form plastic into continuous lengths with uniform cross-sections like pipes, rods, or sheets. The plastic is fed into an extruder which heats and melts it before forcing it through a die. The shape of the die determines the shape of the extruded plastic. Common products made through extrusion molding include pipes, hoses, siding, fencing, deck railings, and plastic bags.