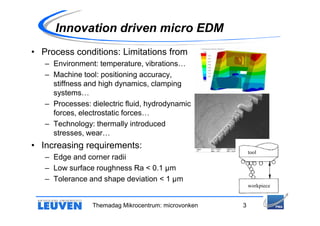

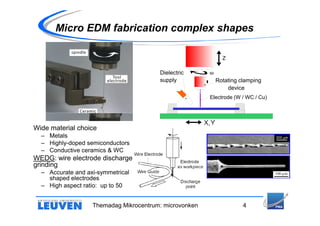

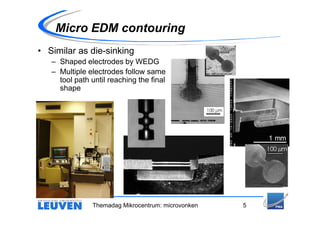

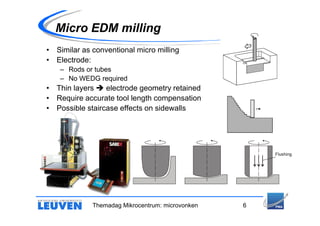

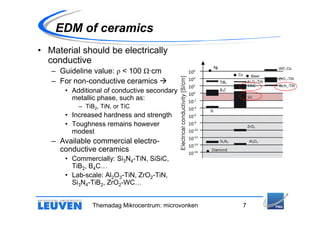

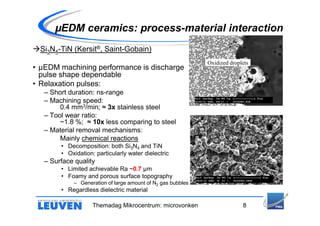

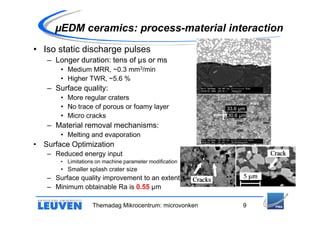

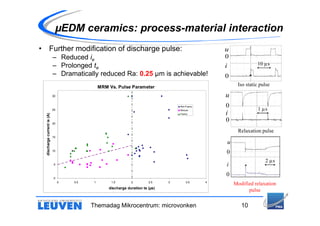

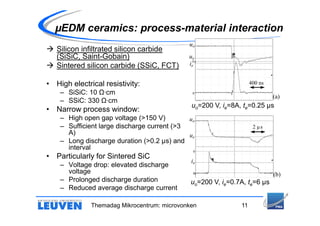

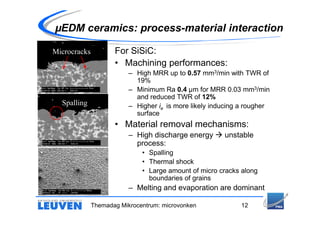

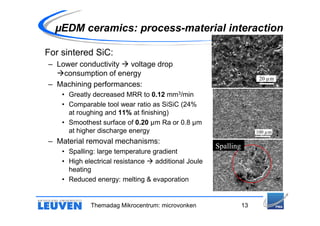

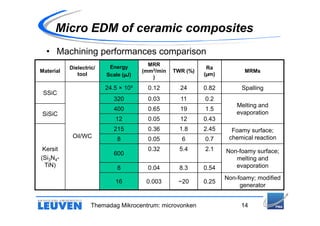

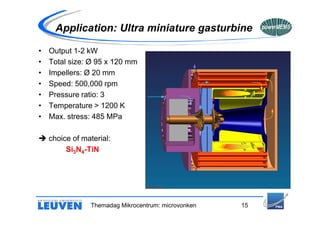

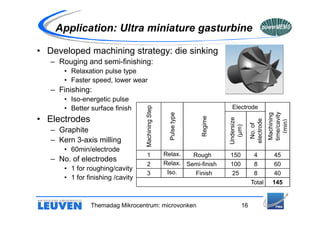

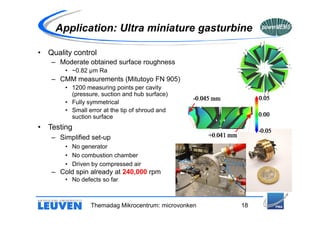

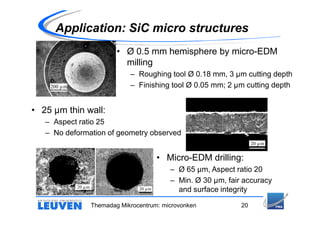

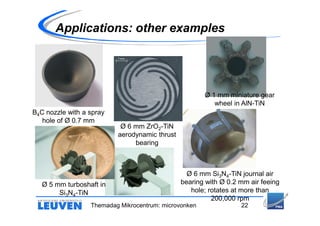

The document discusses micro electrical discharge machining (EDM) of ceramic materials, highlighting its advantages such as high accuracy and independence from mechanical properties. It elaborates on the interaction between process parameters and ceramic materials, detailing specific applications and performance metrics for ultra miniature turbine components. The necessity for tailored modifications in EDM machines to optimize machining outcomes is emphasized along with ongoing research directions.