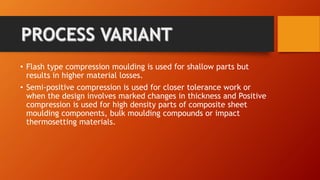

(1) Compression molding is a manufacturing process used to mold thermosetting materials under heat and pressure in a mold cavity.

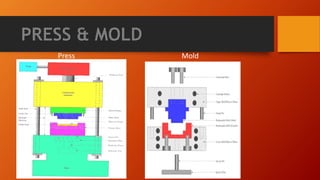

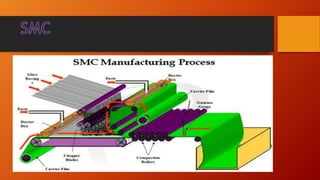

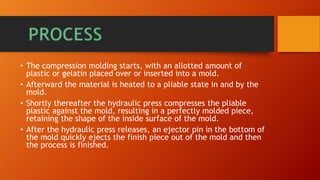

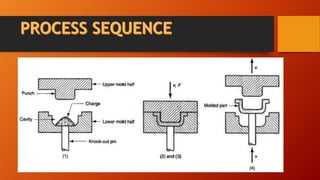

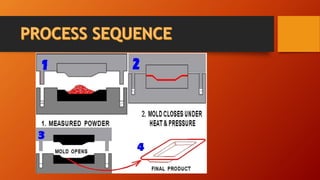

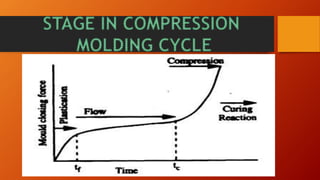

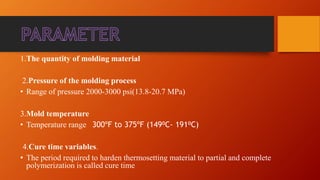

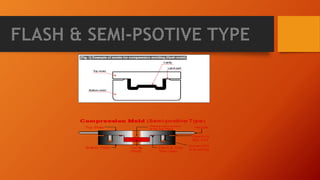

(2) The process involves preheating the molding material, placing it into the mold, applying pressure using a hydraulic press, and allowing the material to cure.

(3) Compression molding is commonly used to make electrical parts, dinnerware, gears, buttons, and automotive and medical components. It allows for high volume, low-cost production with minimal material waste.