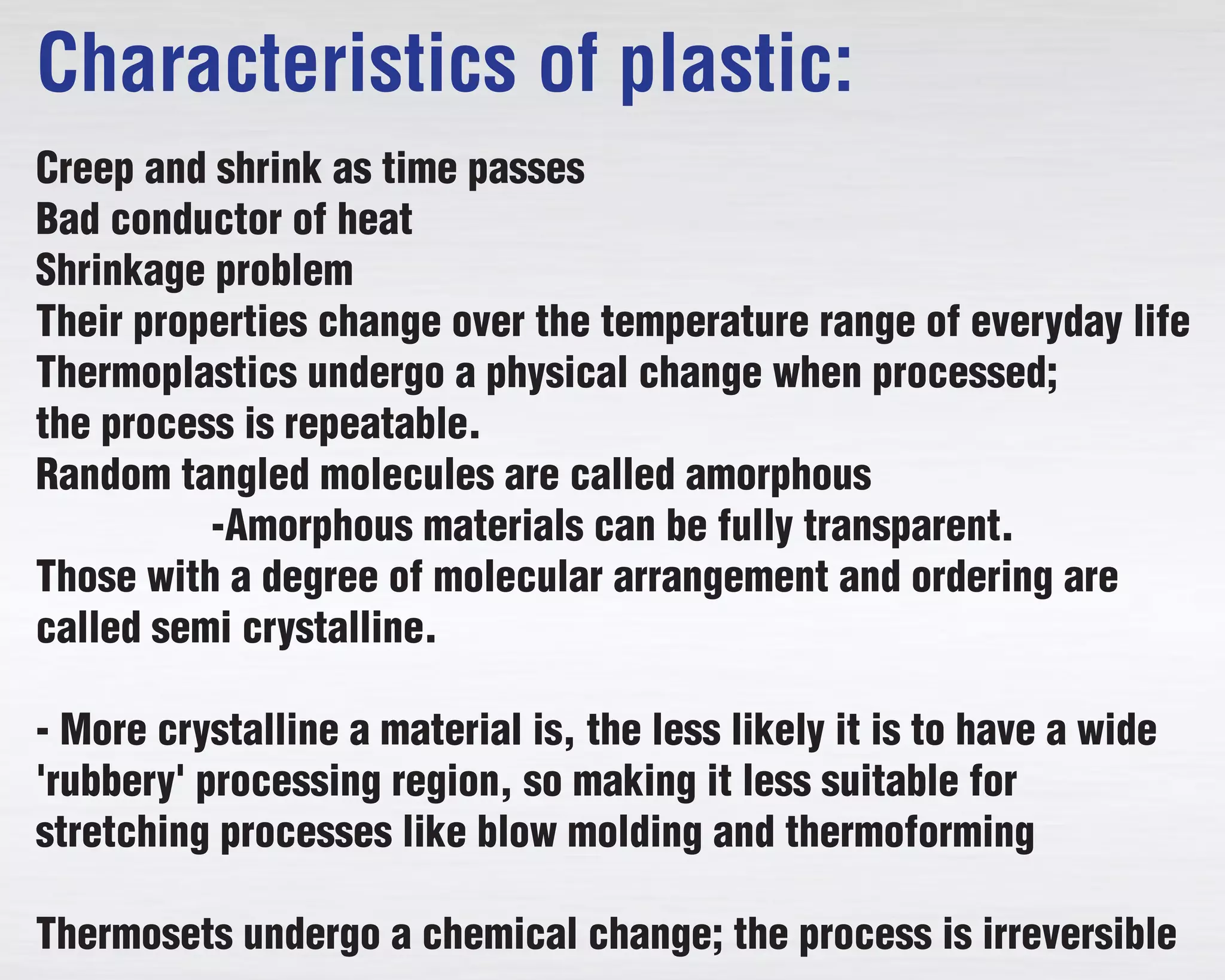

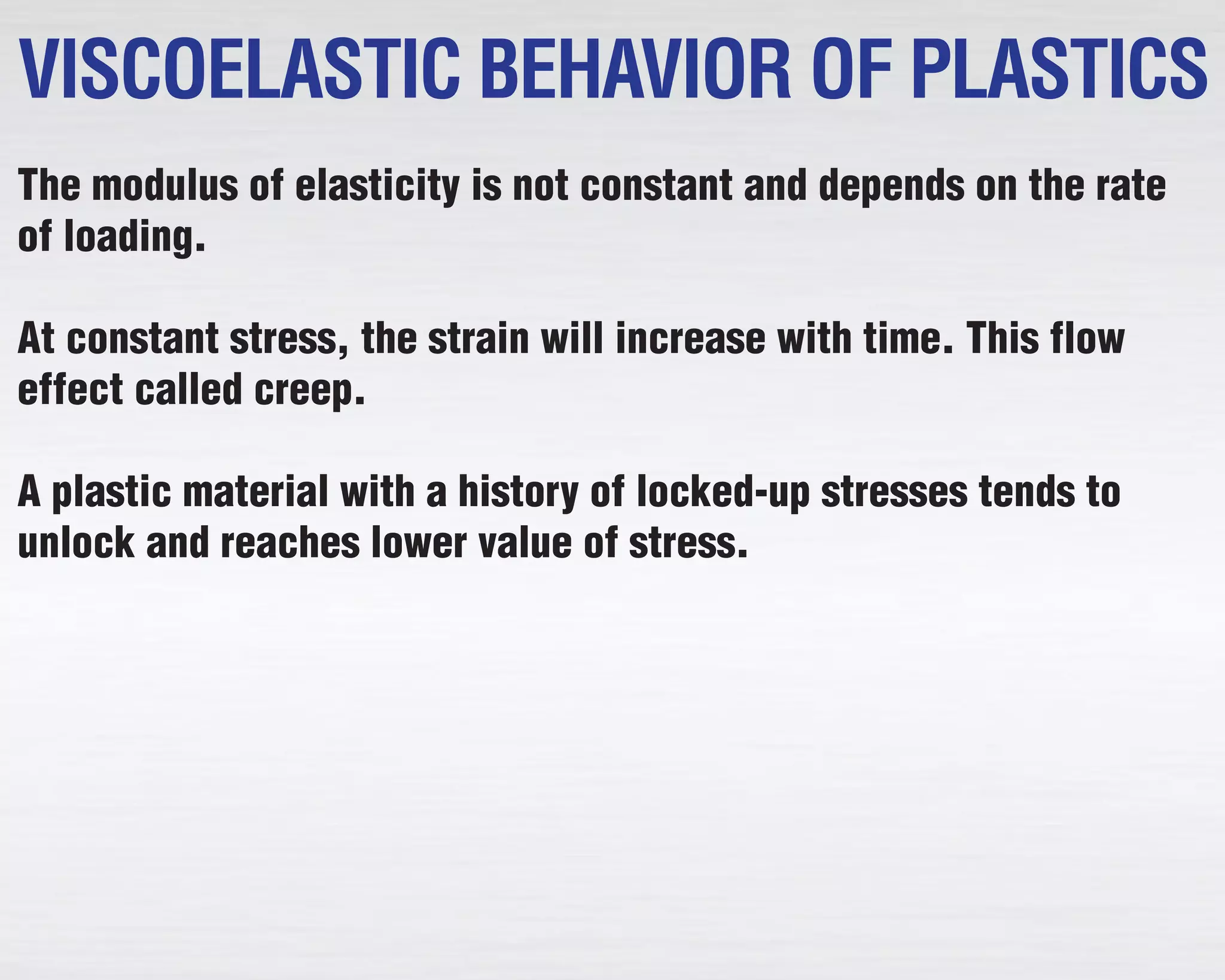

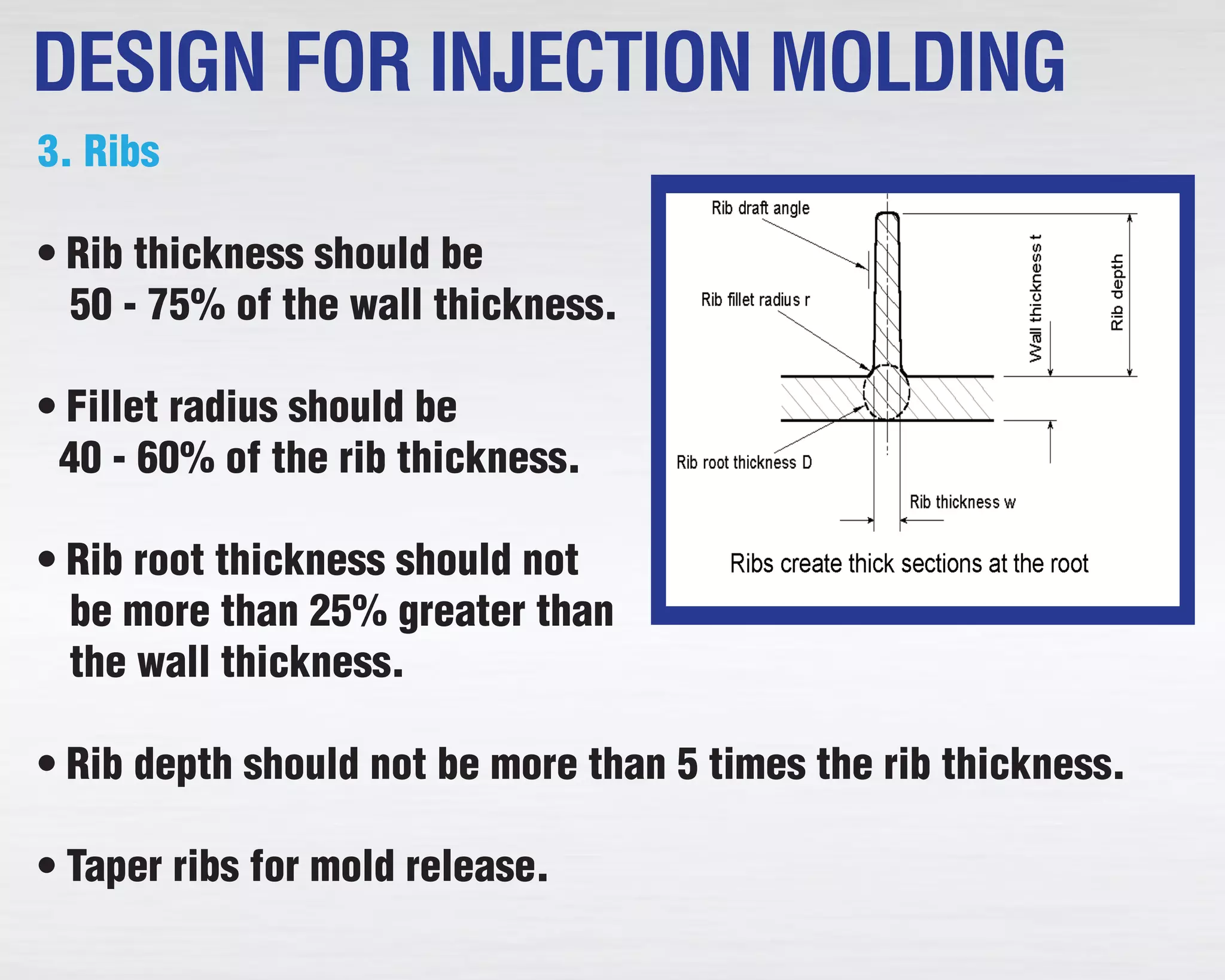

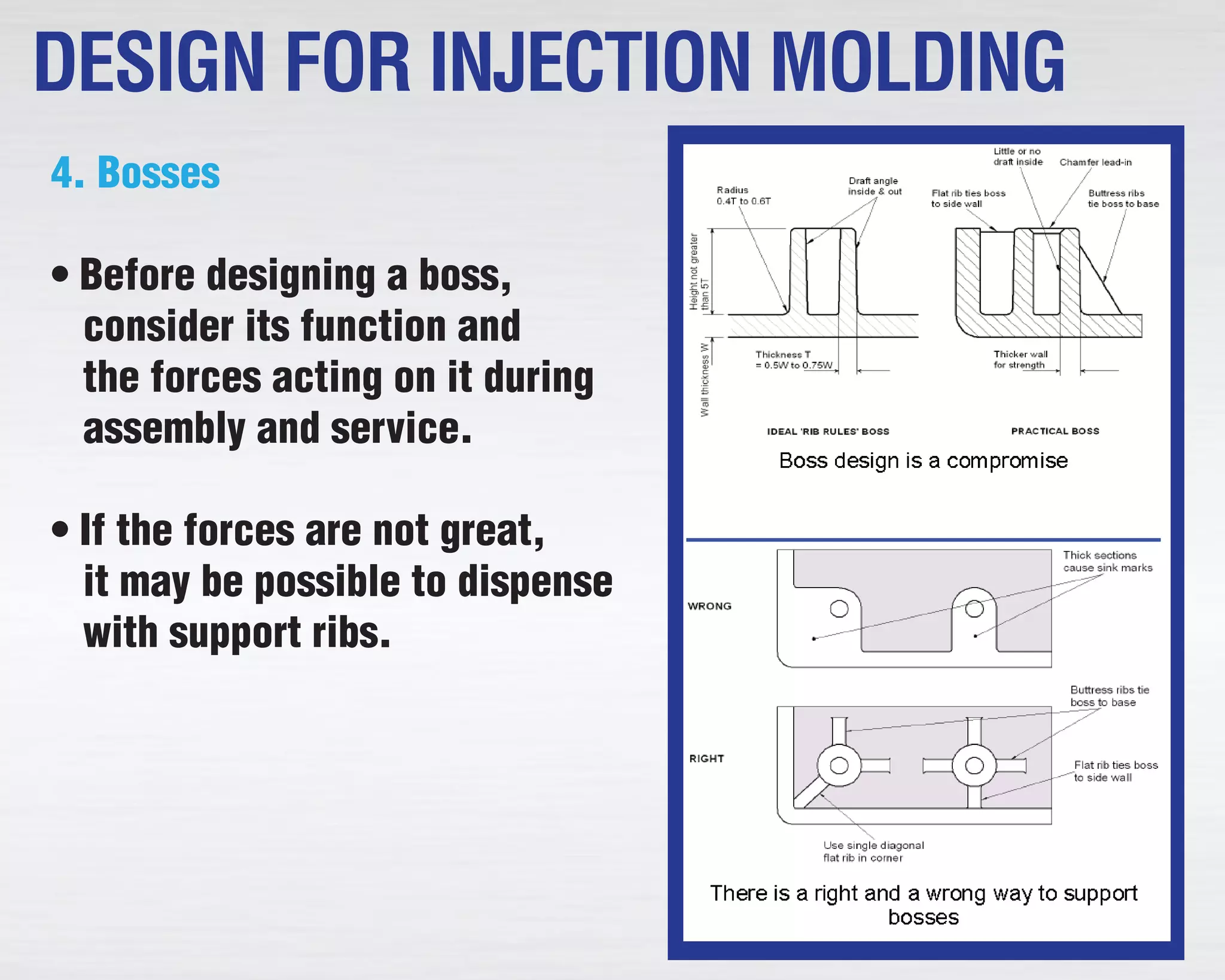

The document provides an overview of plastic materials, detailing types such as thermoplastics and thermosetting plastics, their characteristics, and design considerations for manufacturing. Key design rules include managing wall thickness, avoiding sharp corners, and ensuring appropriate rib and boss designs for injection molding. Additionally, it addresses the importance of recycling plastics and offers insights into various molding processes, such as pressure molding and blow molding.