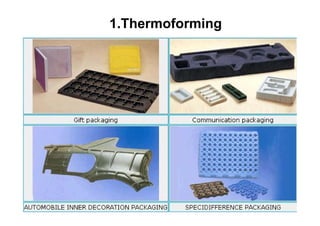

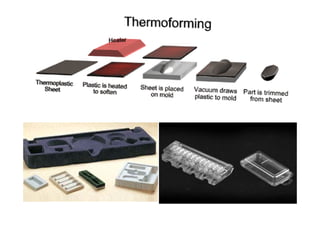

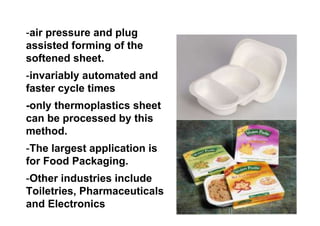

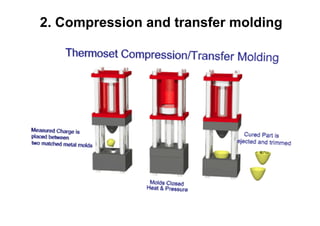

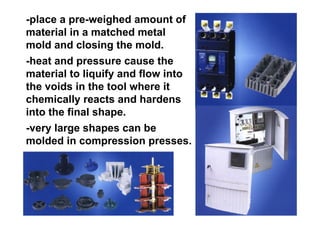

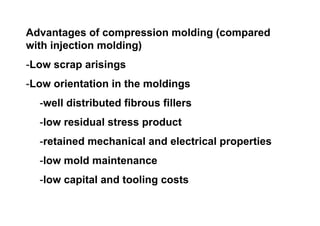

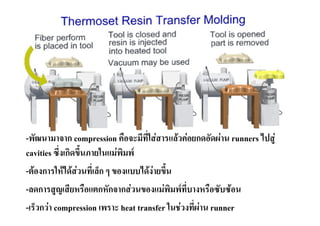

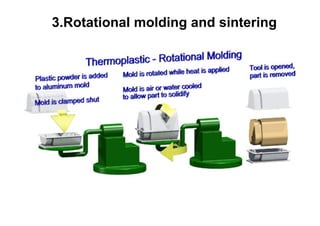

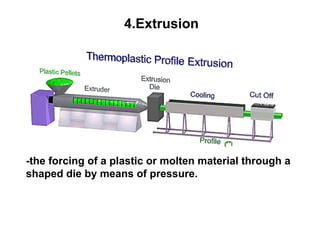

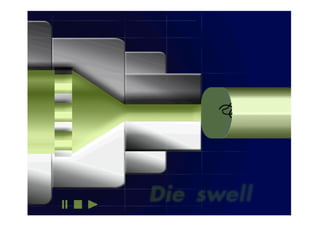

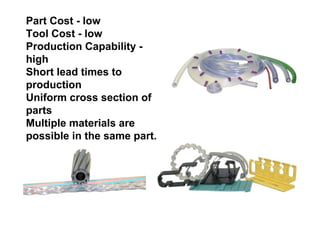

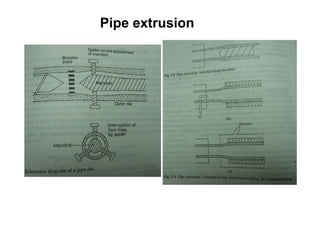

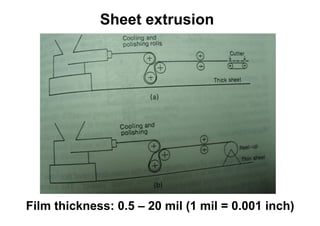

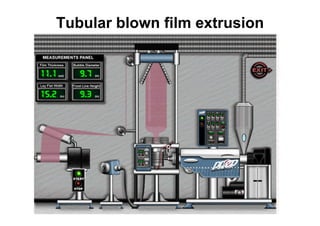

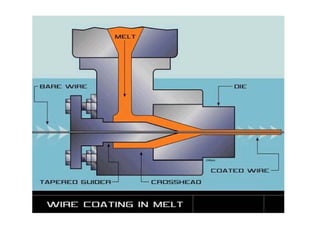

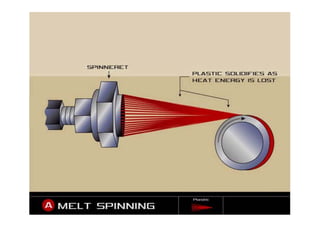

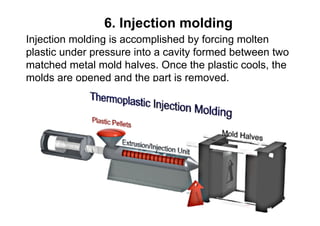

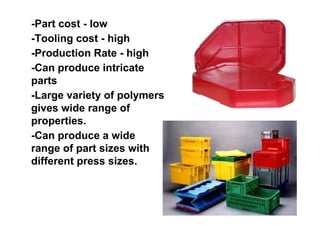

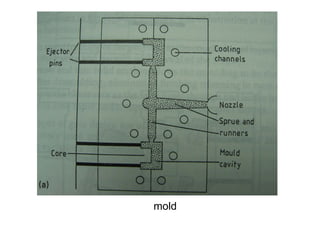

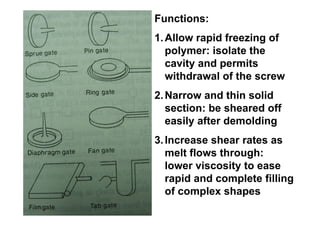

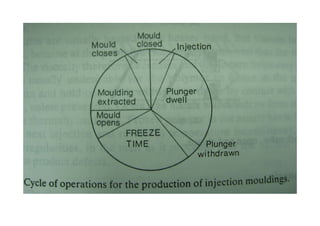

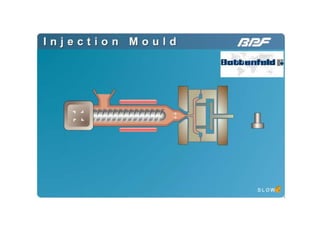

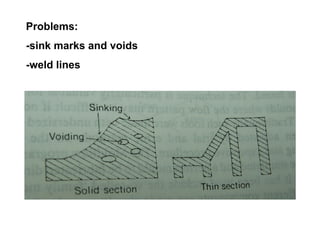

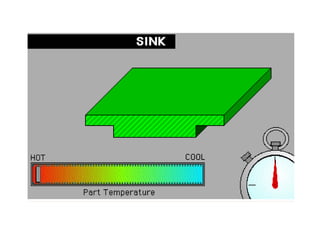

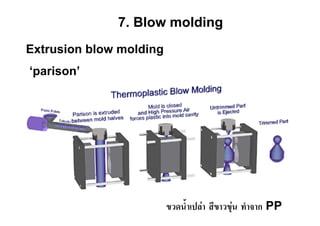

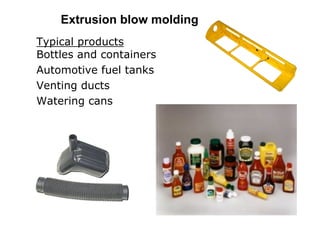

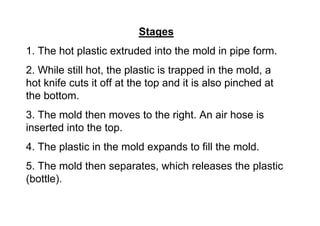

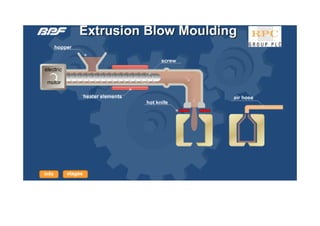

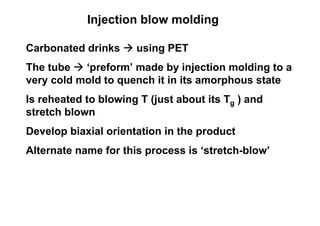

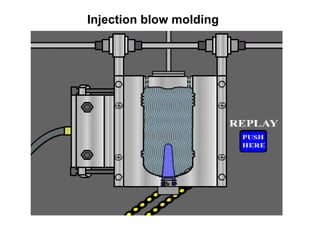

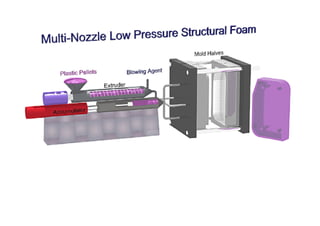

This document discusses various polymer processing techniques. It begins by outlining three general phases of plastics processes: heating, shaping/forming under constraint, and cooling. It then describes specific processes like thermoforming, compression and transfer molding, rotational molding, extrusion and extrusion-based processes, injection molding, and blow molding. For each process, it provides details on how it works, its advantages and disadvantages, and common applications.