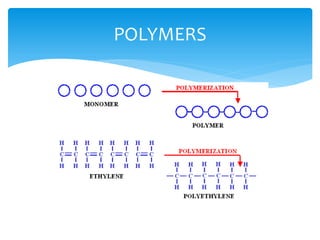

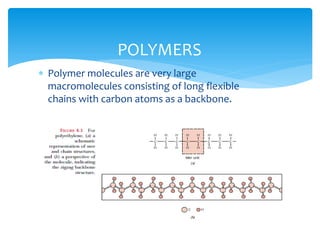

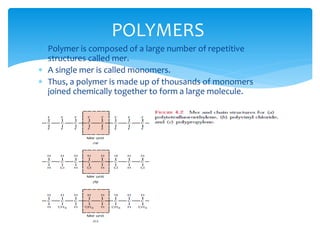

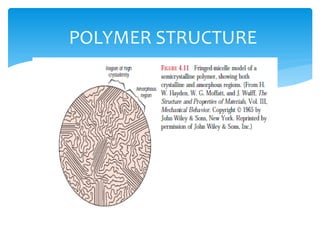

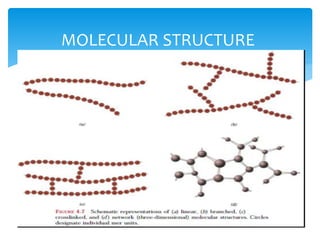

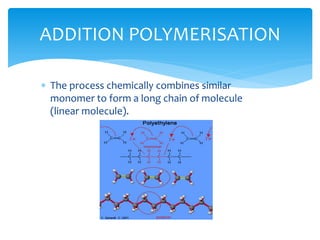

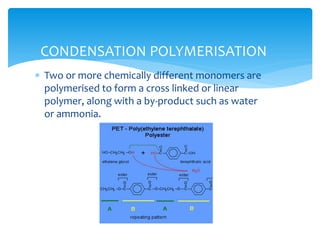

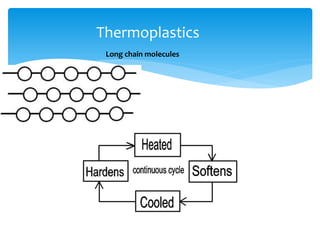

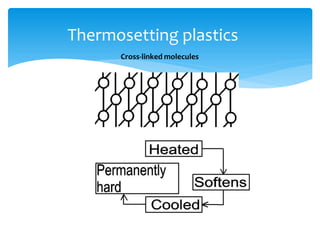

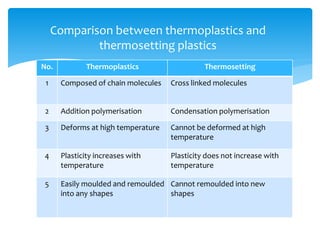

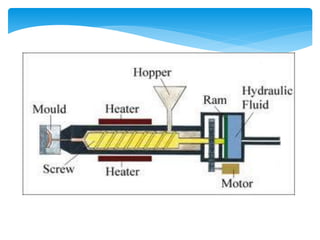

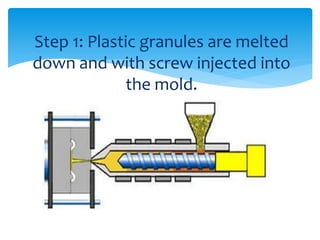

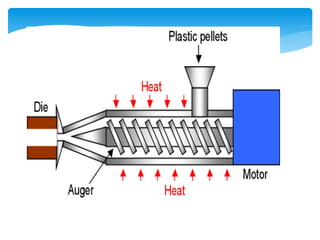

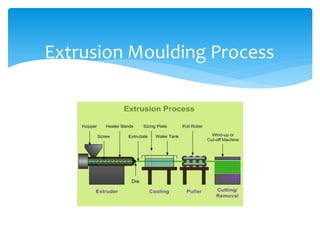

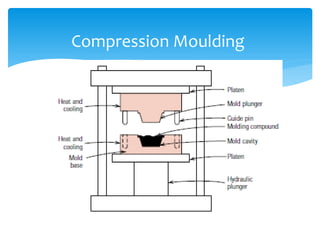

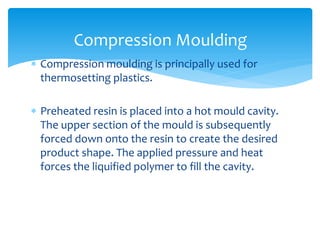

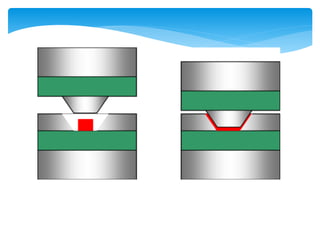

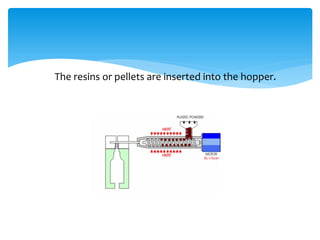

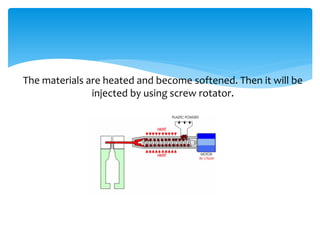

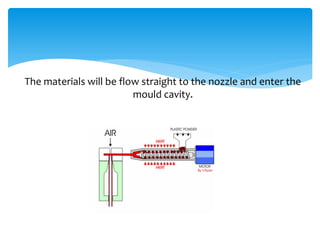

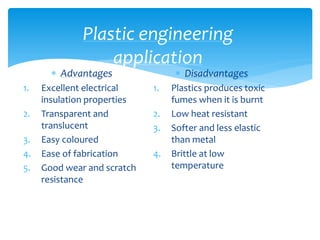

Chapter 6 discusses plastics, defining them as organic polymers that can be molded when heated and retain their shape upon cooling. It covers various types of polymers, including linear, branched, and crosslinked polymers, as well as their synthesis through addition and condensation polymerization. The chapter also distinguishes between thermoplastics, which can be reshaped multiple times, and thermosetting plastics, which cure permanently, and outlines different molding processes including injection, extrusion, and compression molding.