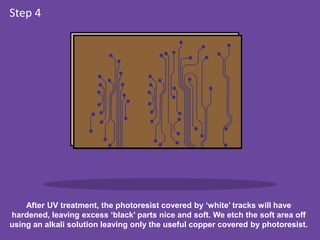

The document outlines the PCB manufacturing process at Hi5 Electronics, detailing each step from converting a board design into Gerber files to final shipping. Key processes include creating negative images, applying photoresist, etching copper, layering, drilling, and applying protective finishes. Hi5 emphasizes precision and care throughout the manufacturing stages to deliver customized PCBs.