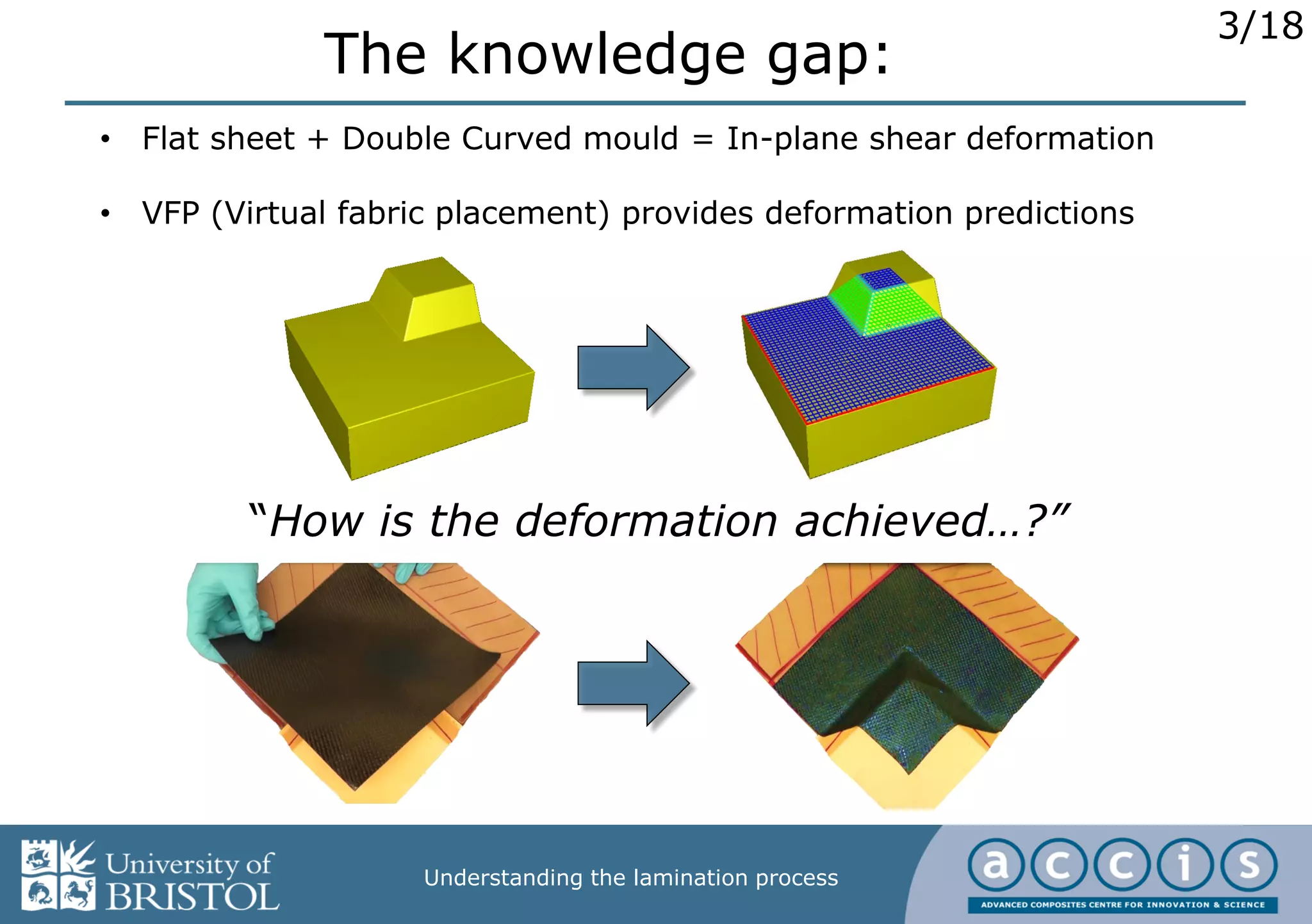

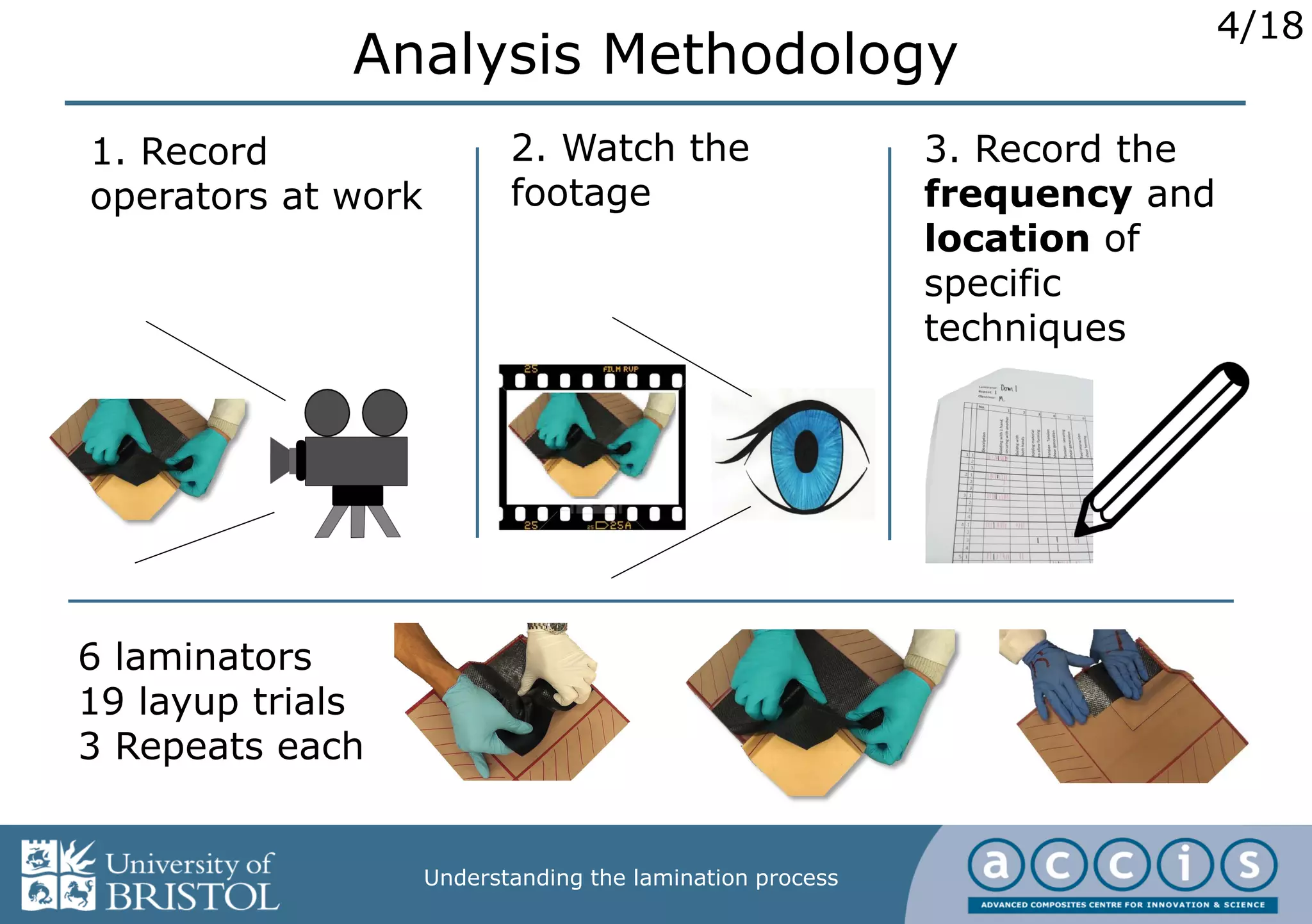

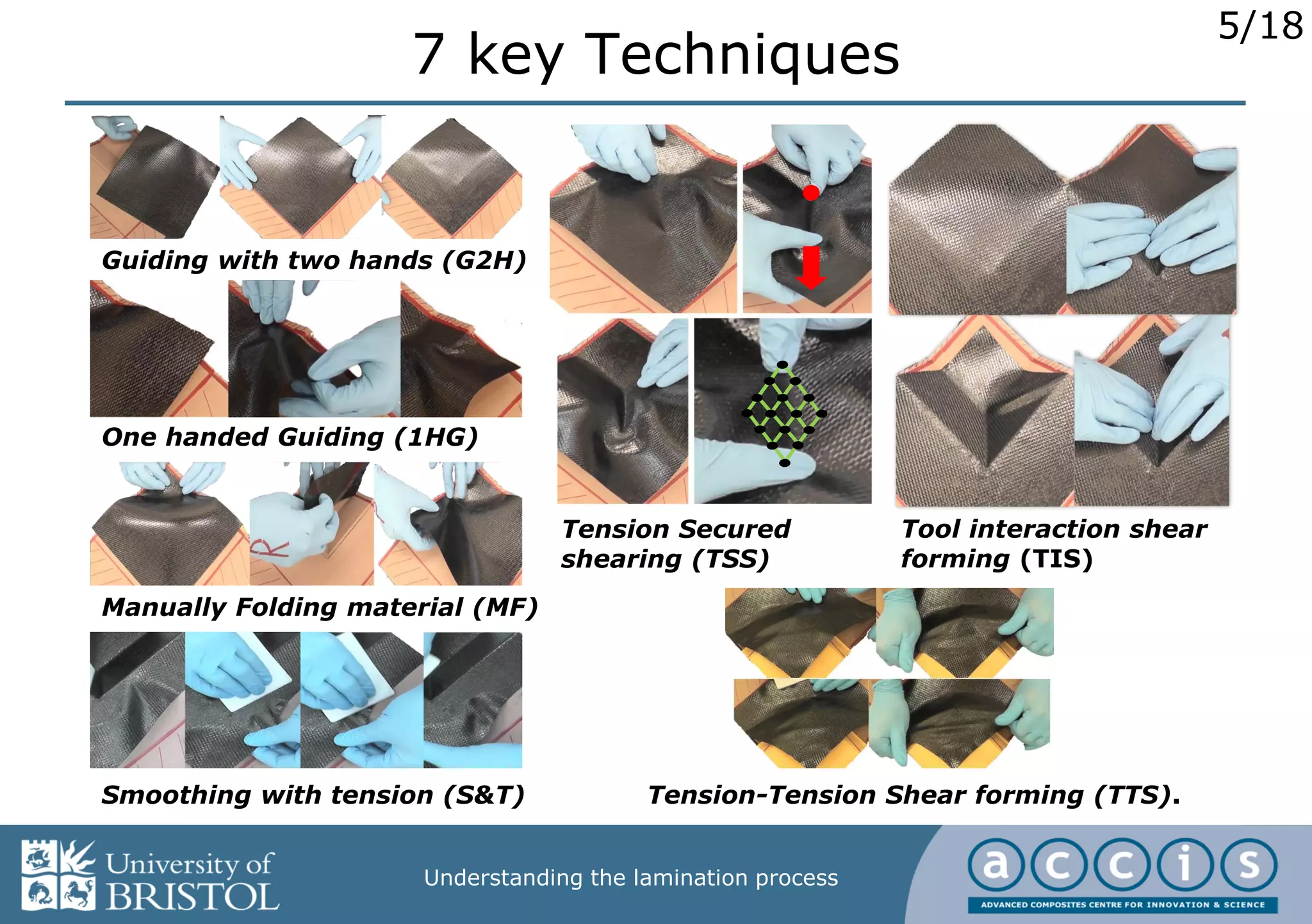

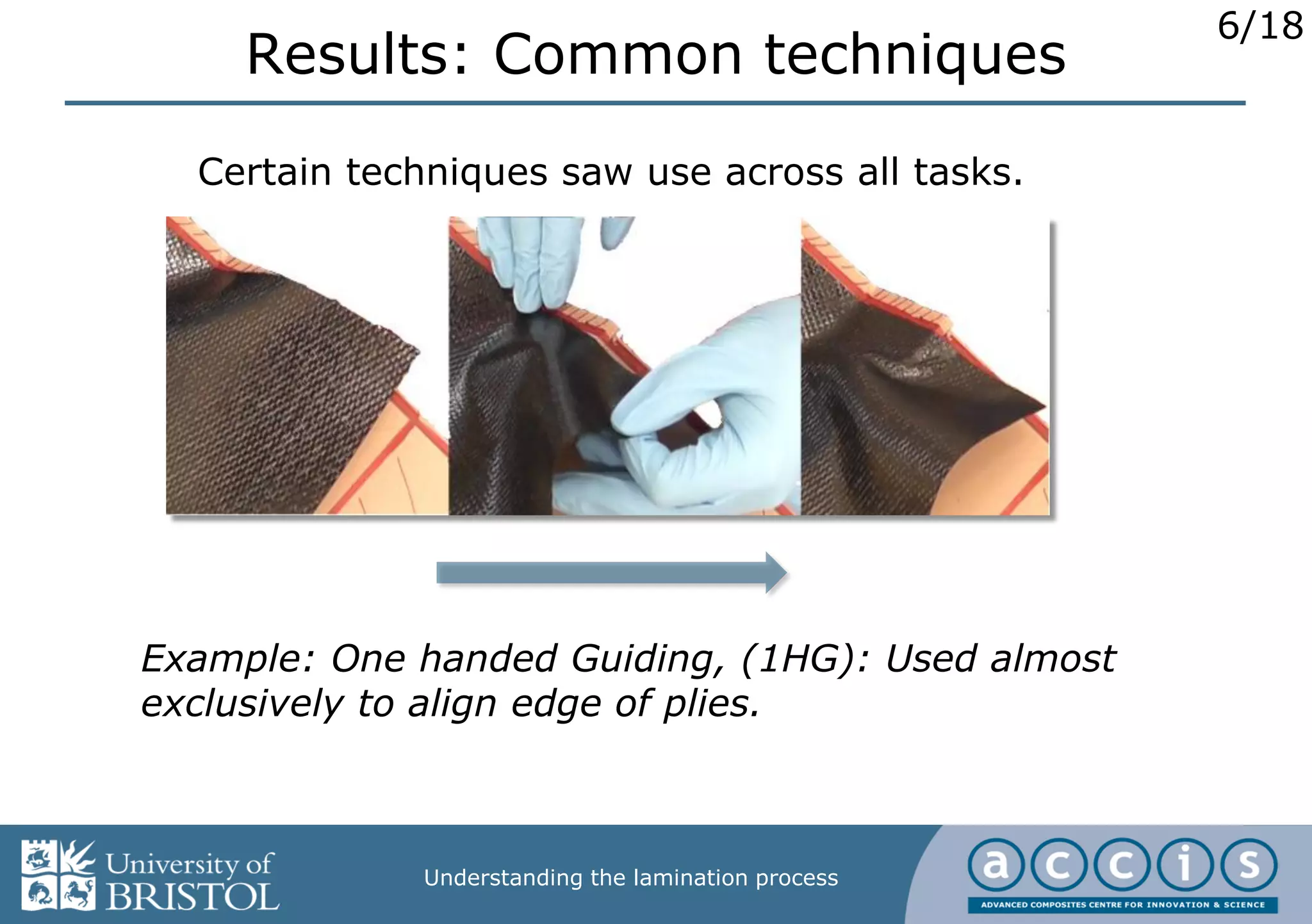

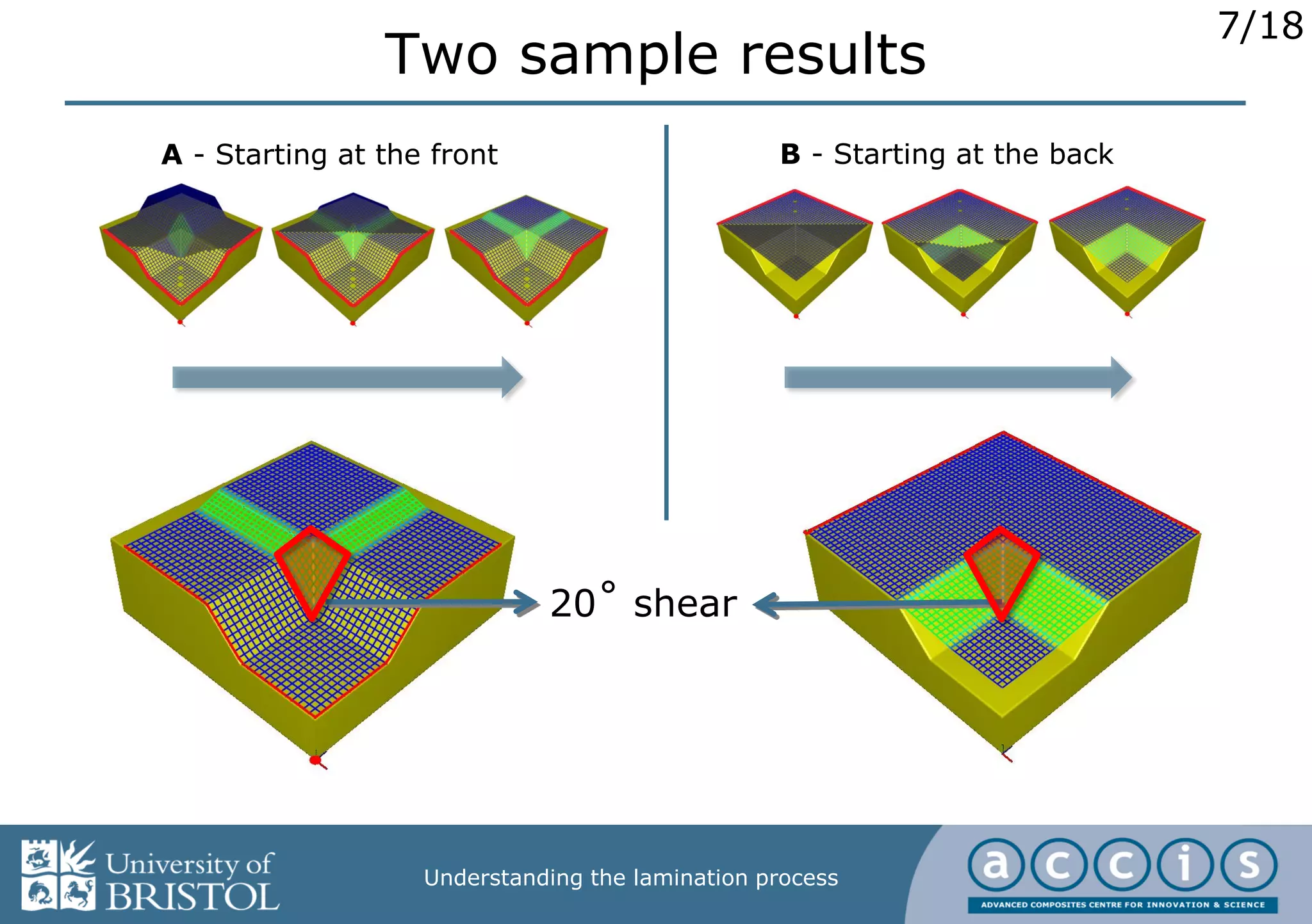

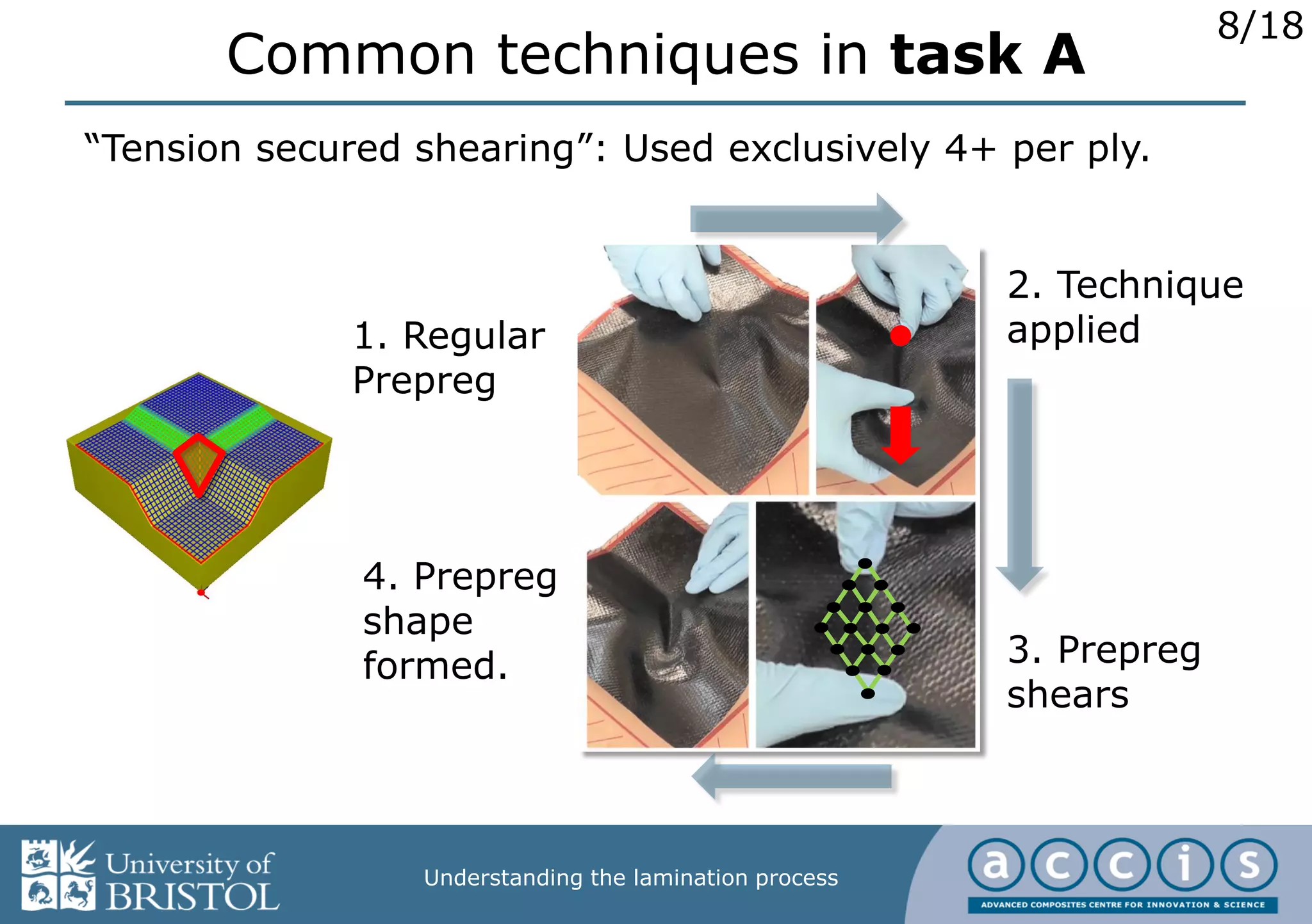

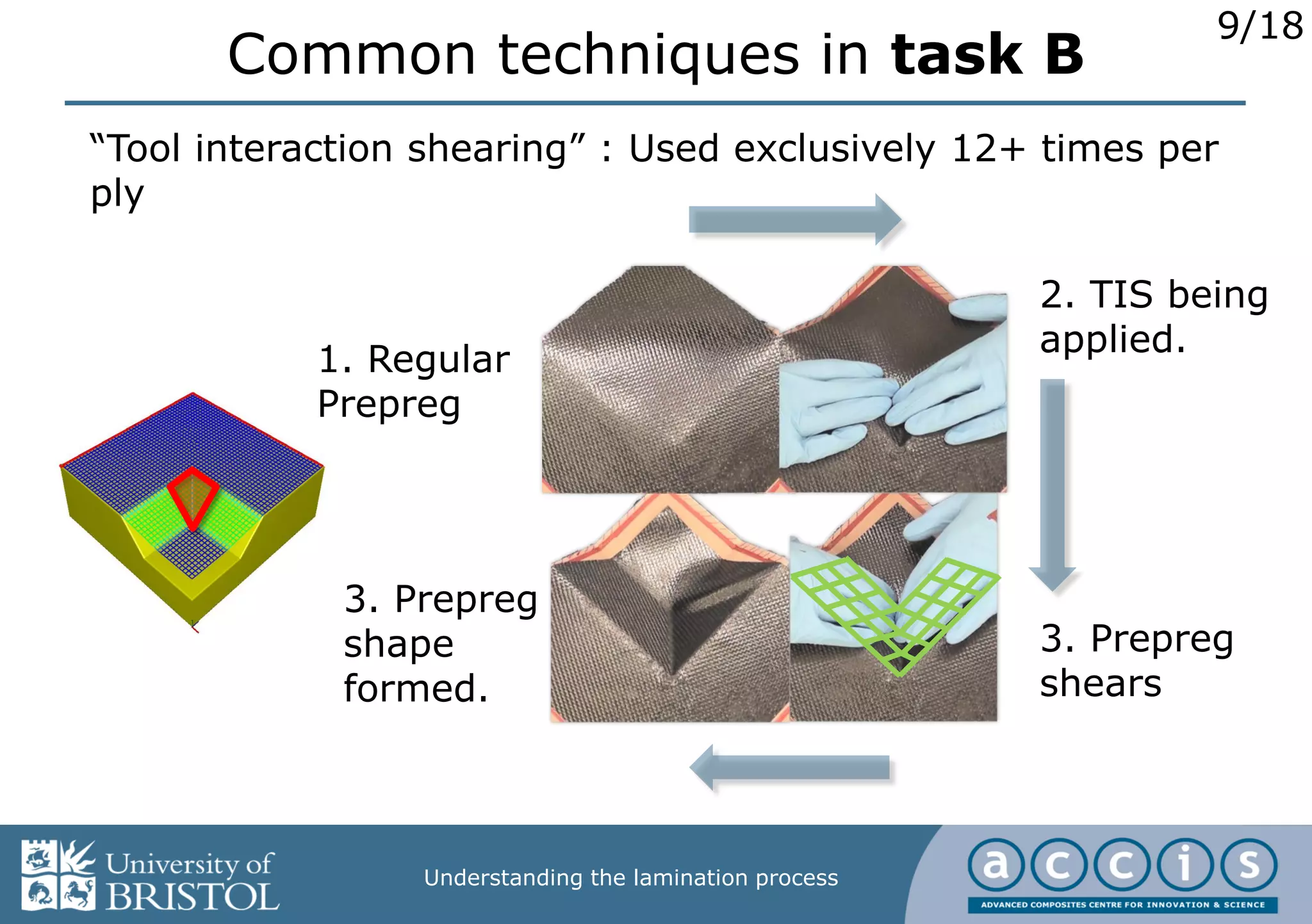

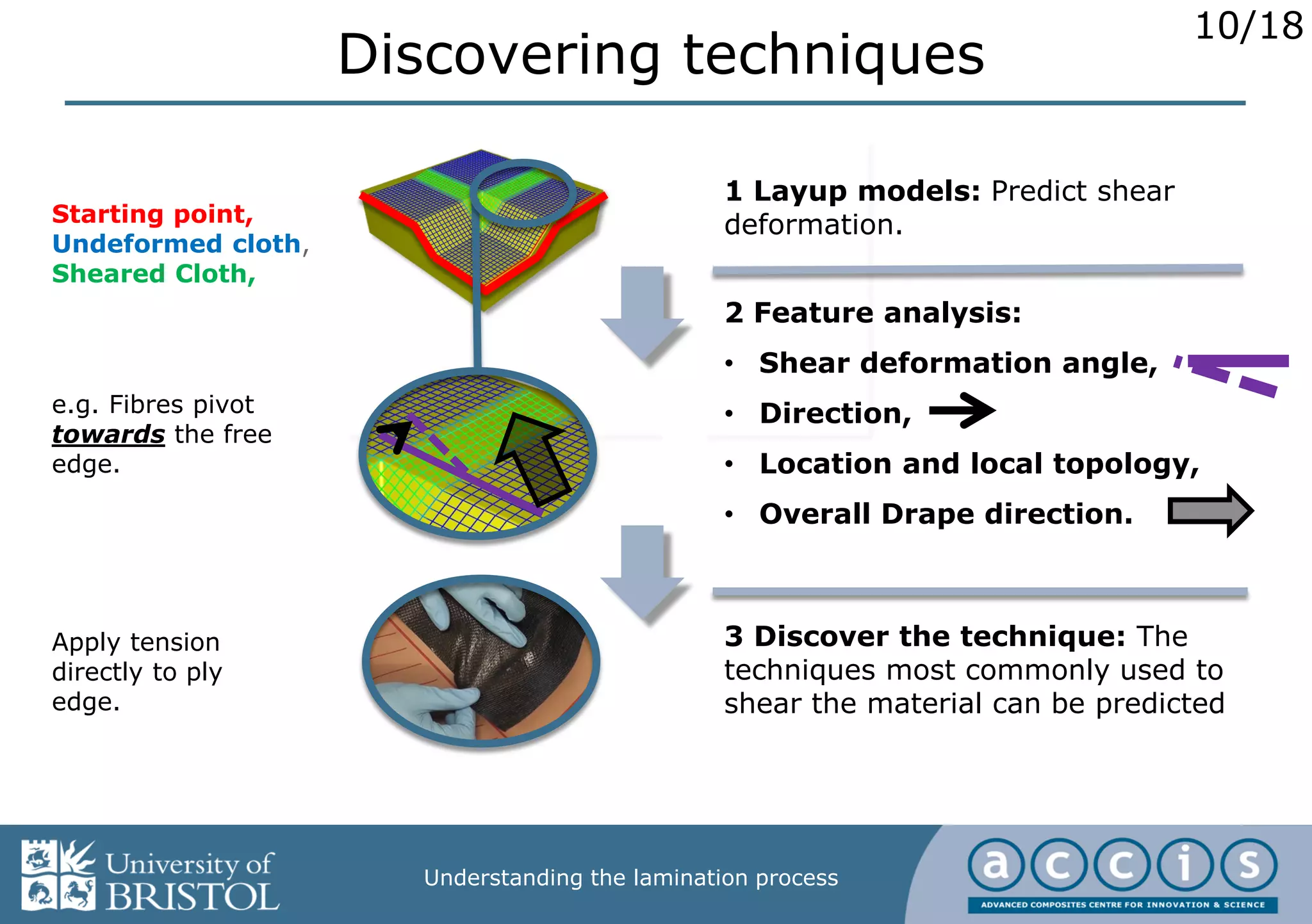

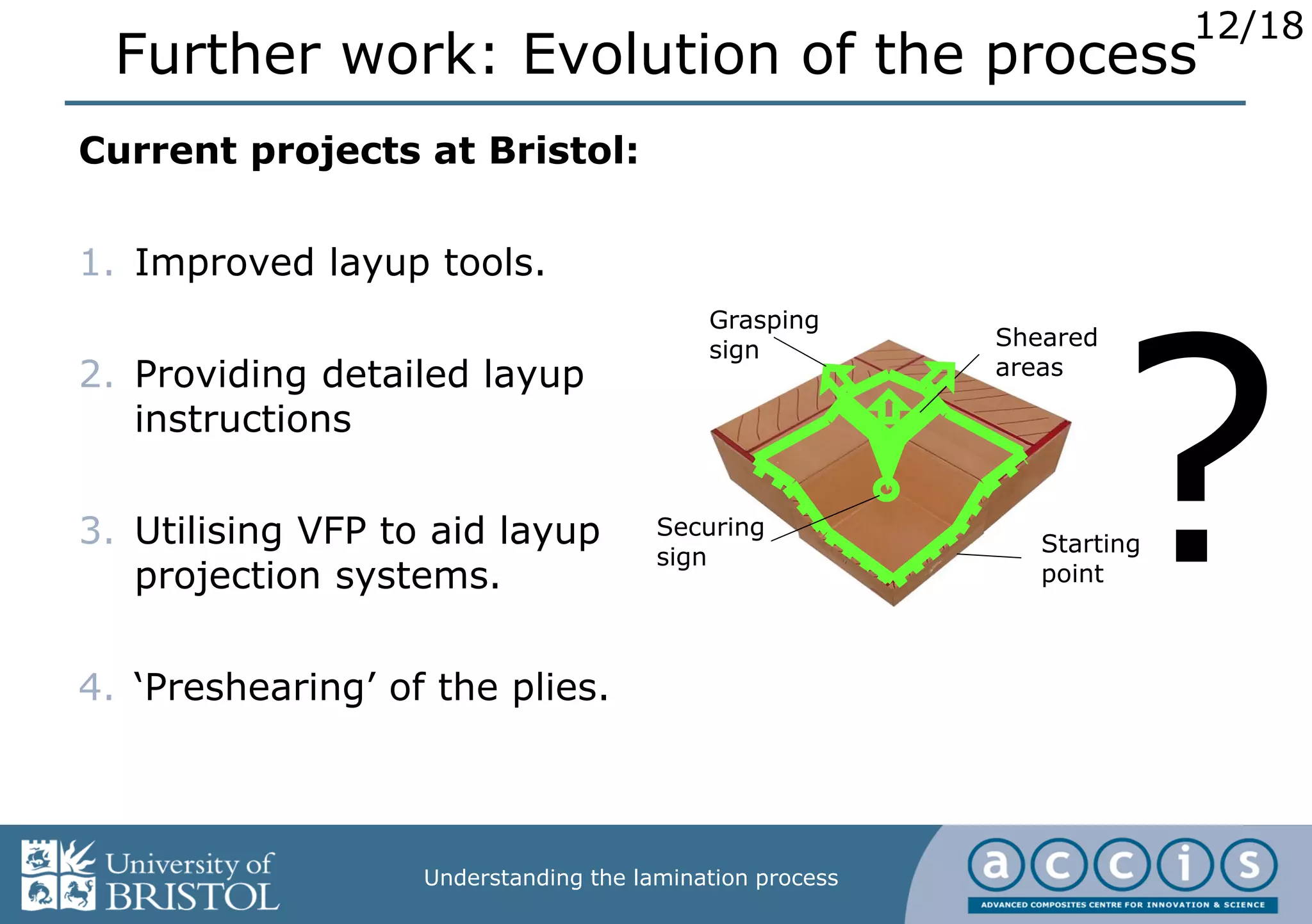

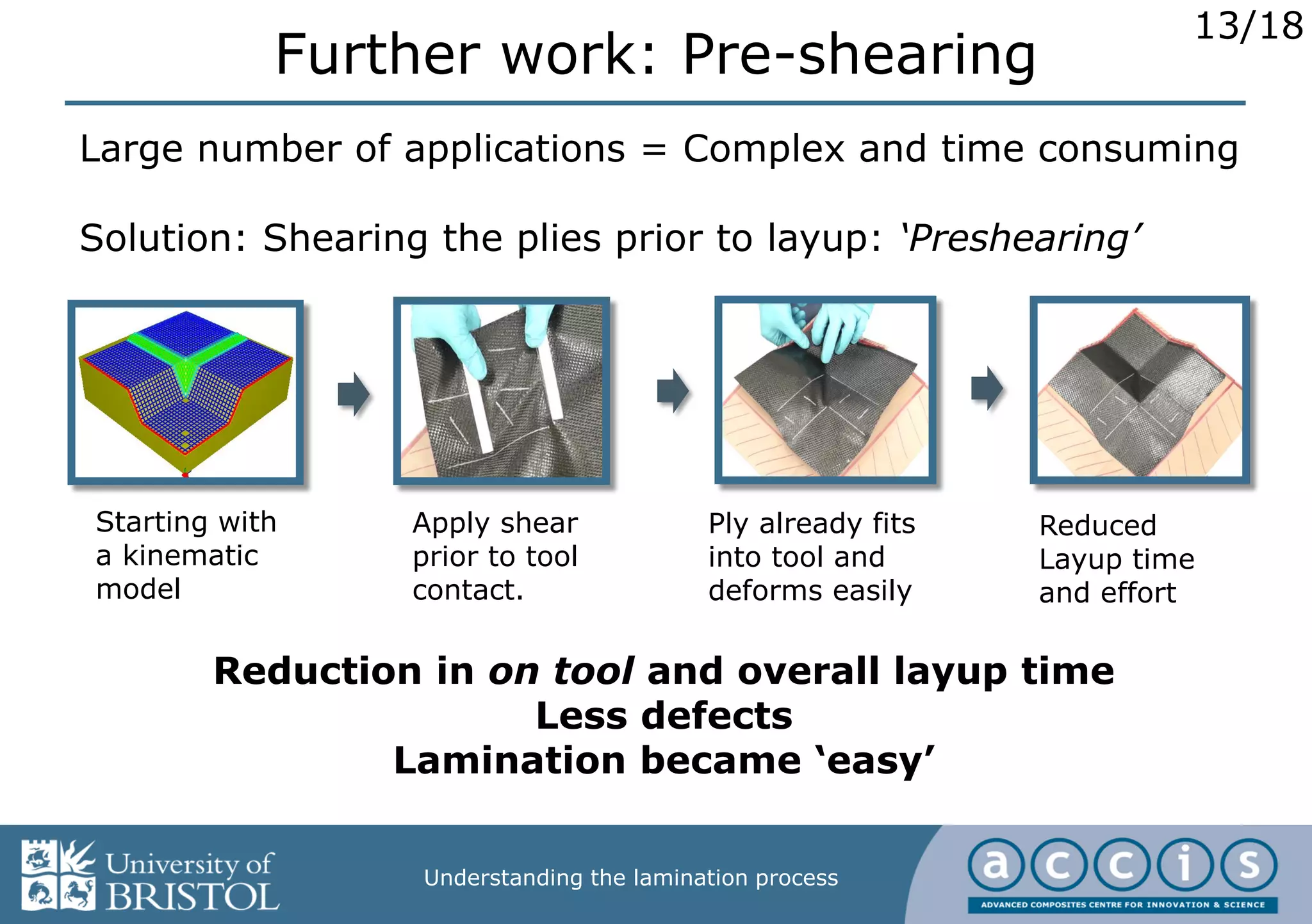

The document discusses the lamination process in composite manufacturing, highlighting seven key techniques used by laminators. It identifies the need for optimization in this traditional process and presents findings on shear deformation predictions and common techniques used during layup. Further work includes improvements in layup tools and pre-shearing methods to enhance efficiency and reduce defects.