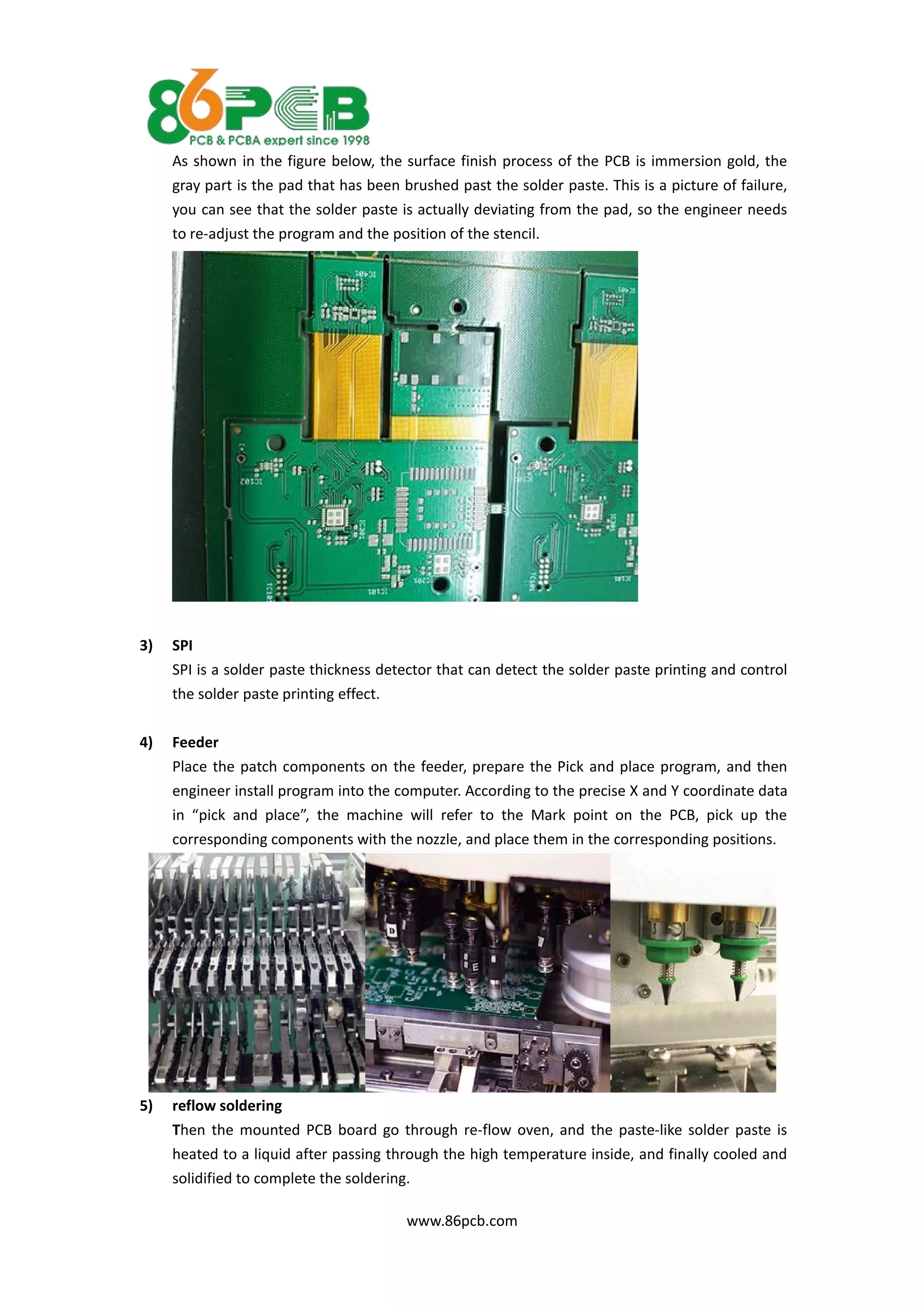

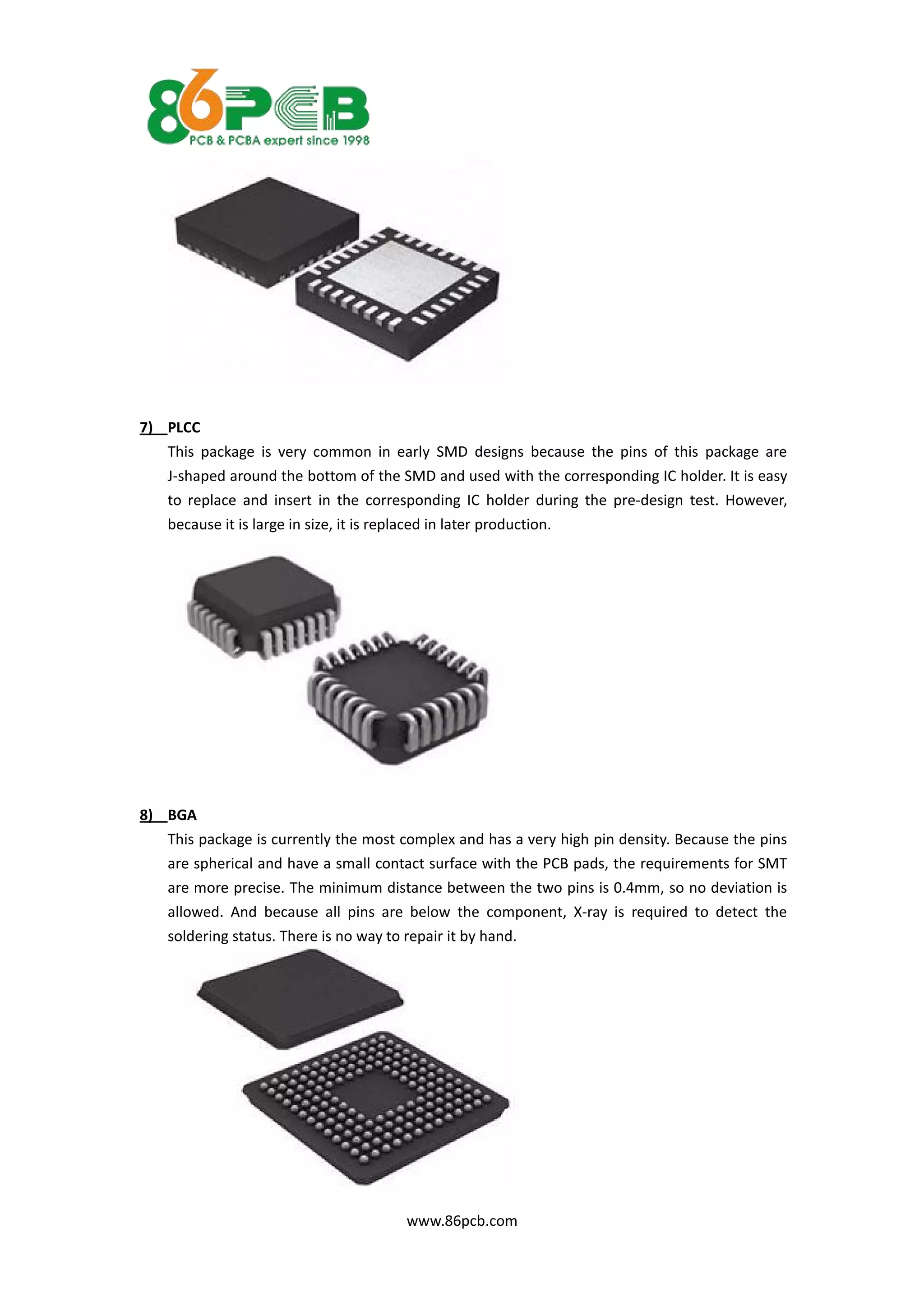

Surface mount technology (SMT) allows electronic components to be mounted directly onto printed circuit boards (PCBs), offering advantages such as reduced size, low cost, and improved performance. The SMT process includes solder paste preparation, printing, component placement, reflow soldering, and inspection, with various types of surface-mounted devices (SMDs) available for different applications. SMDs can be categorized into passive and active components, with distinct features and functionality.