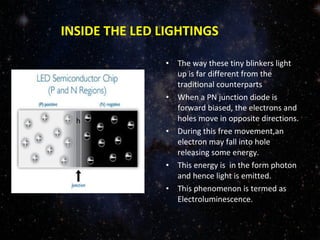

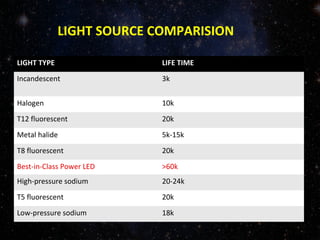

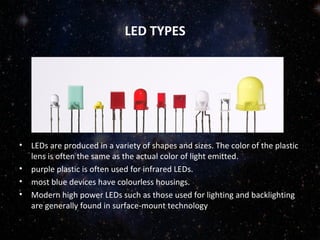

This document provides an overview of LED technology, including its history, types, and benefits. It discusses the development of LEDs from red lights in the 1960s to modern high-brightness blue and white LEDs. Key developments include the invention of high-brightness blue LEDs in the 1990s, which enabled the production of white LEDs through phosphor coating and advanced lighting applications. The document also describes the inner workings of LEDs, comparing their efficiency and lifetime to other light sources, and provides details on connecting, soldering and testing LED circuits.