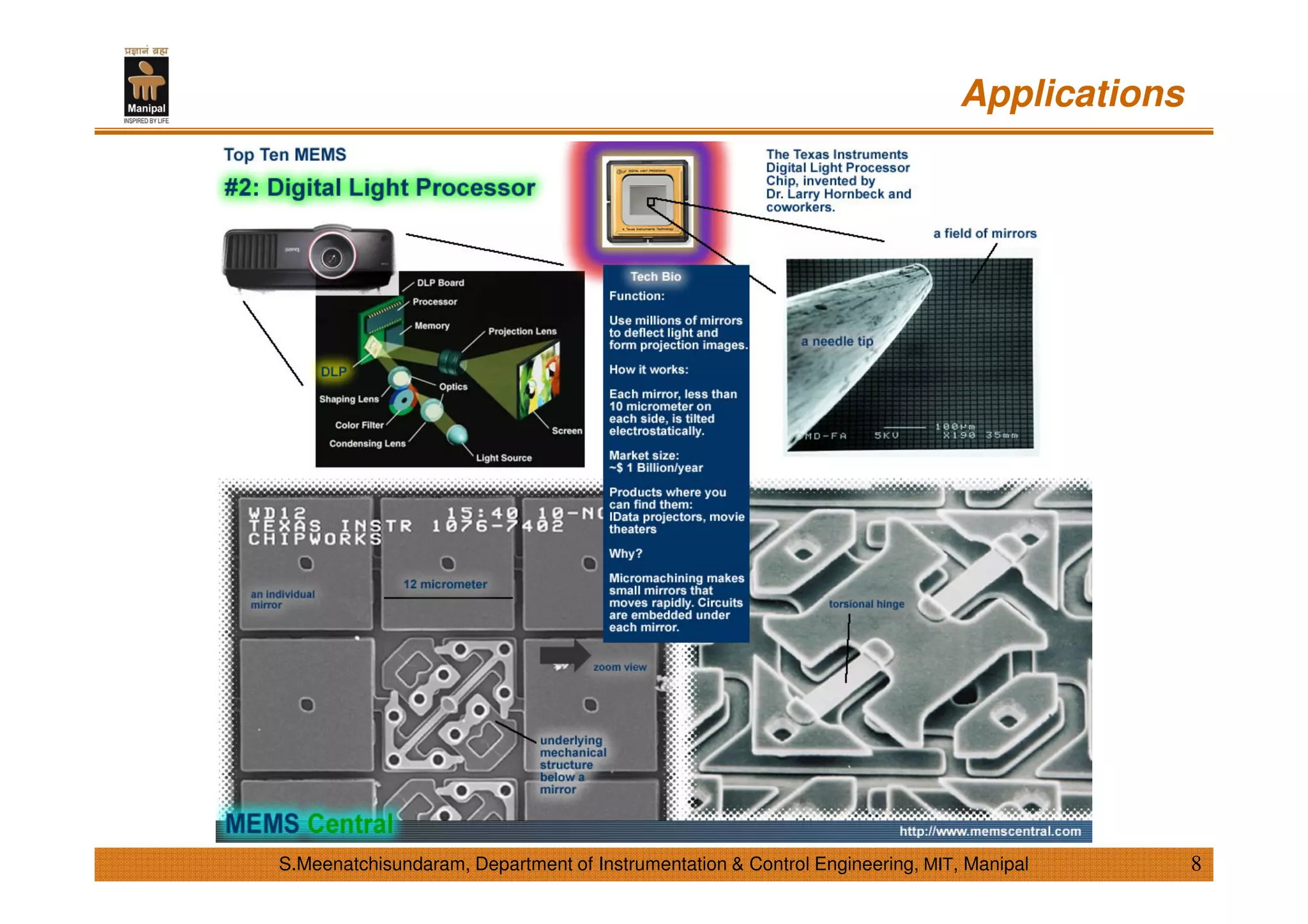

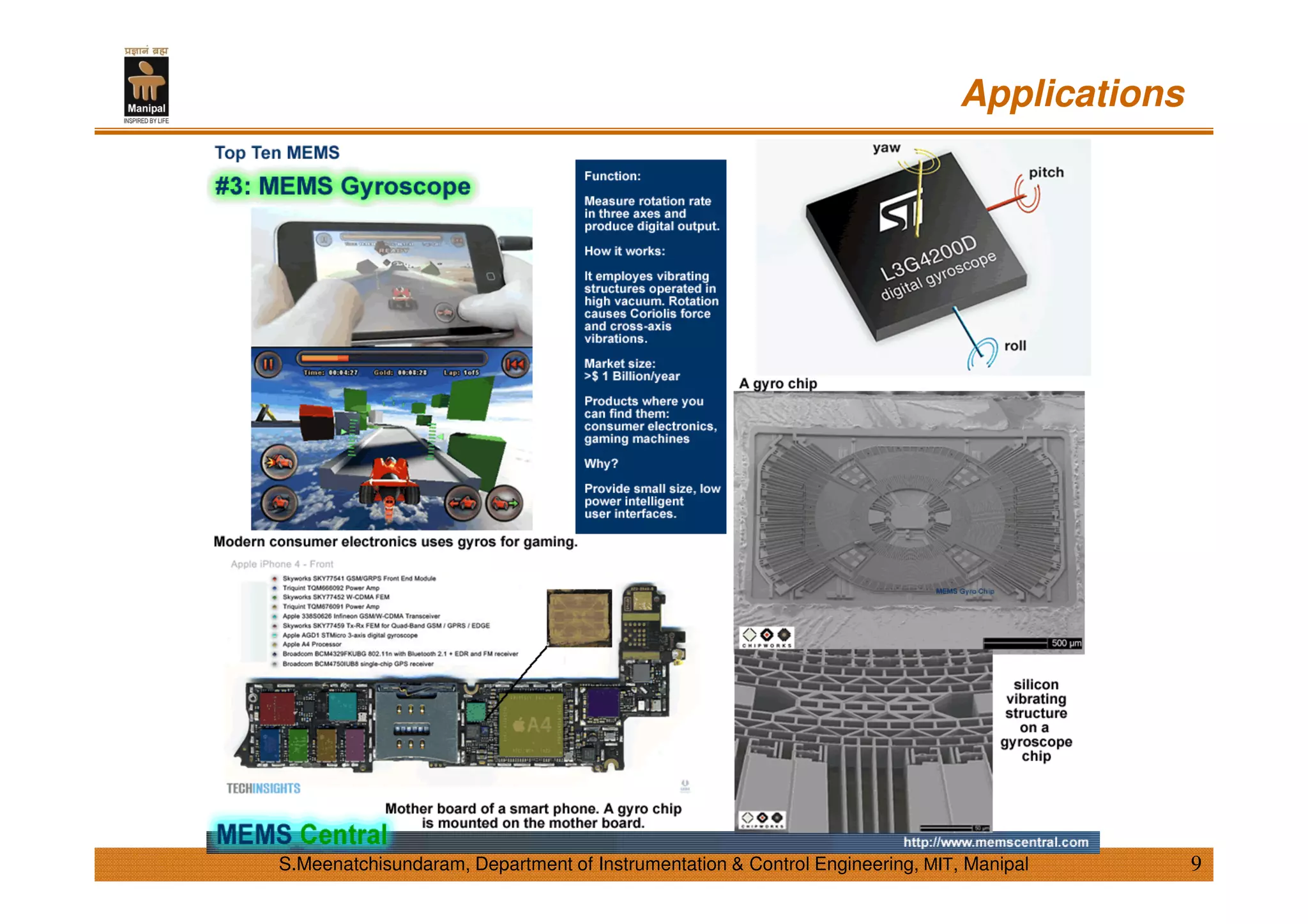

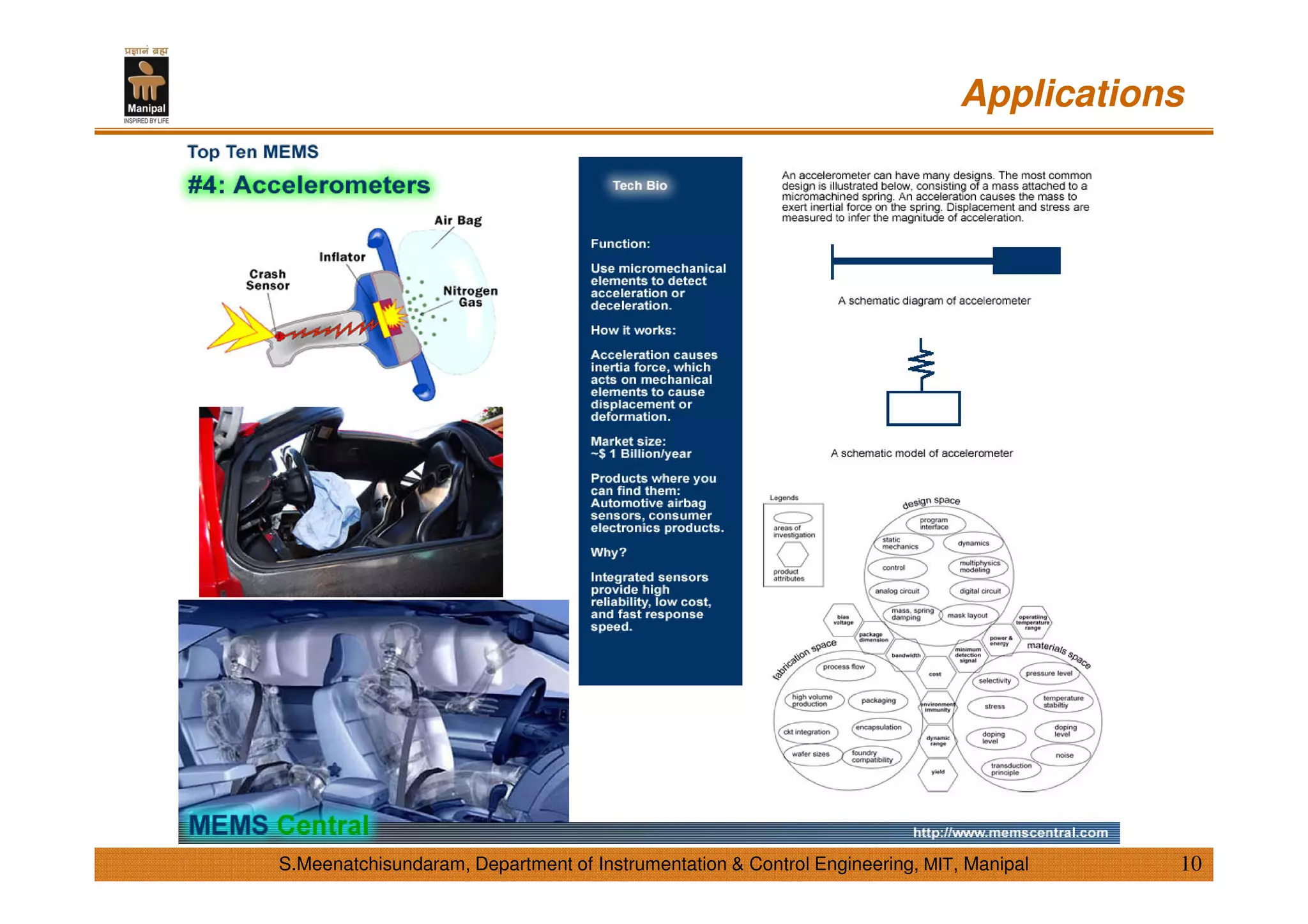

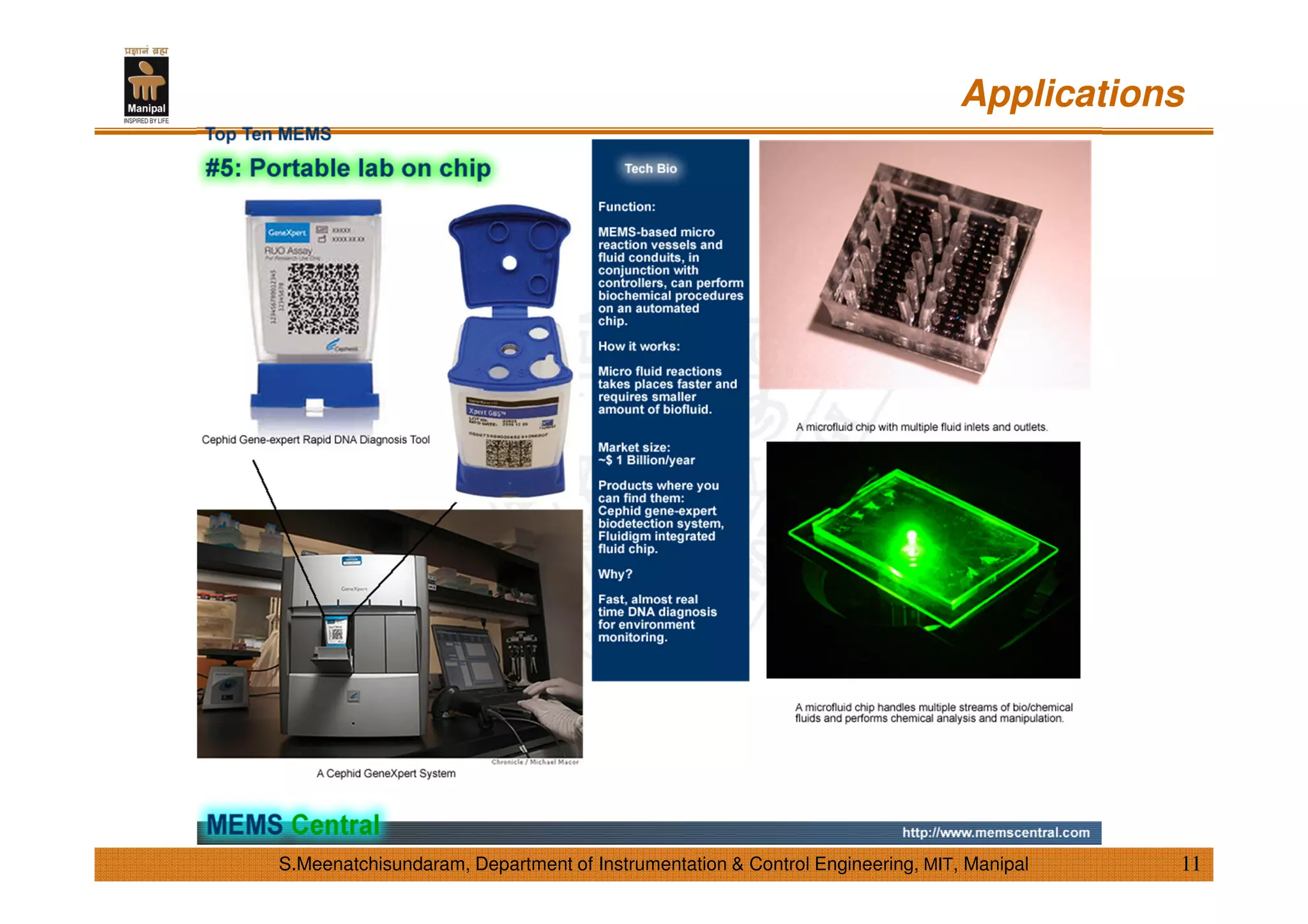

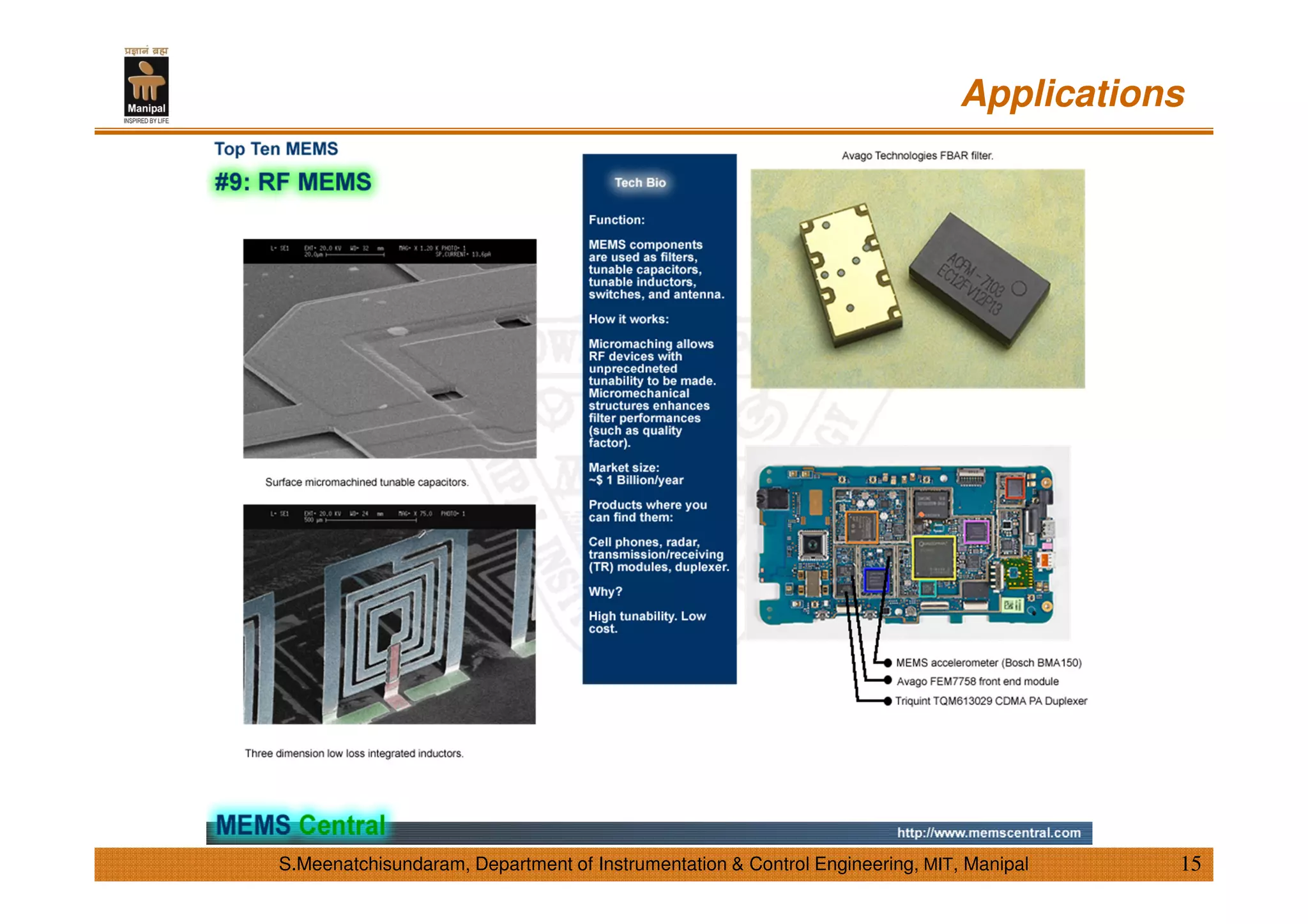

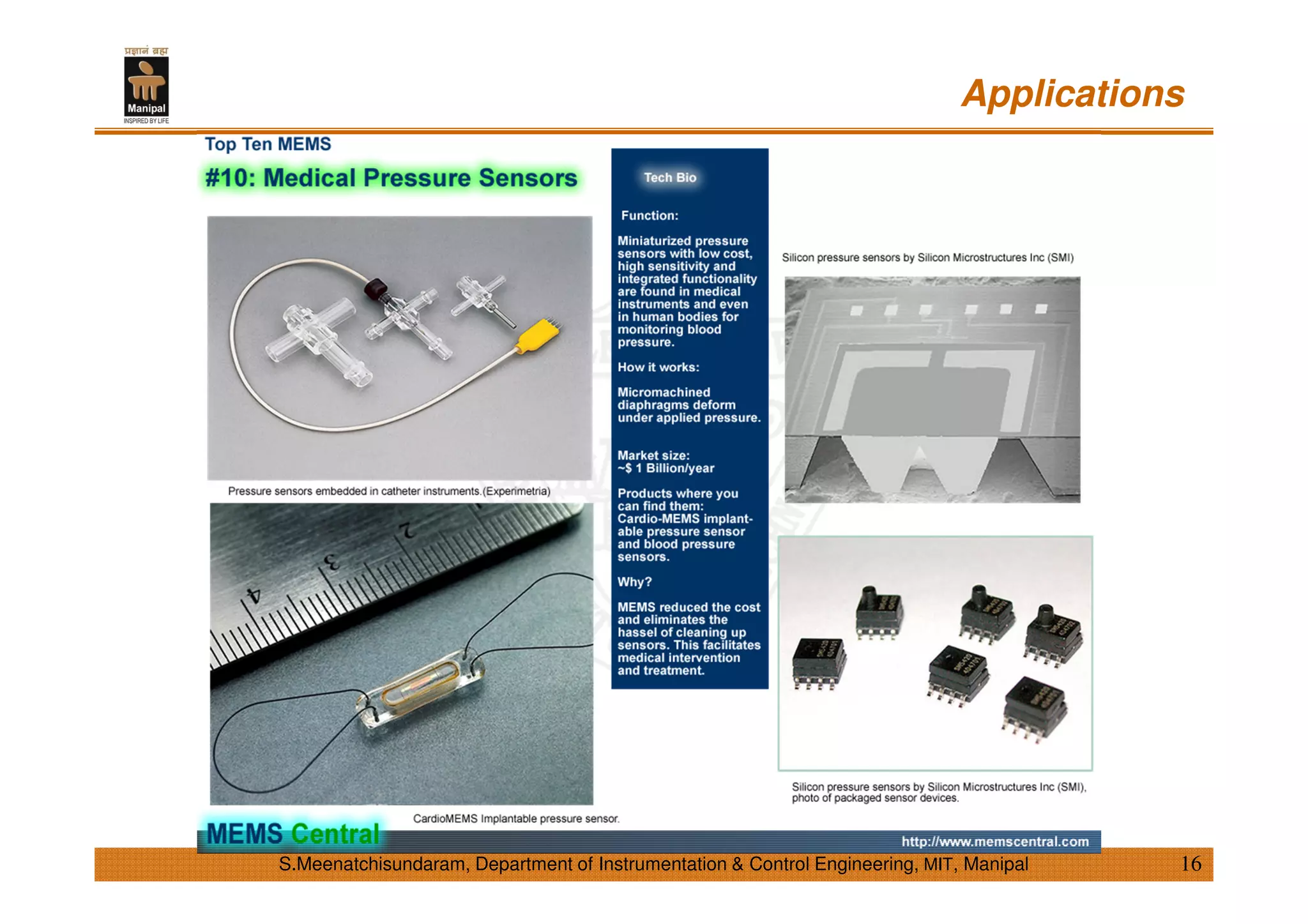

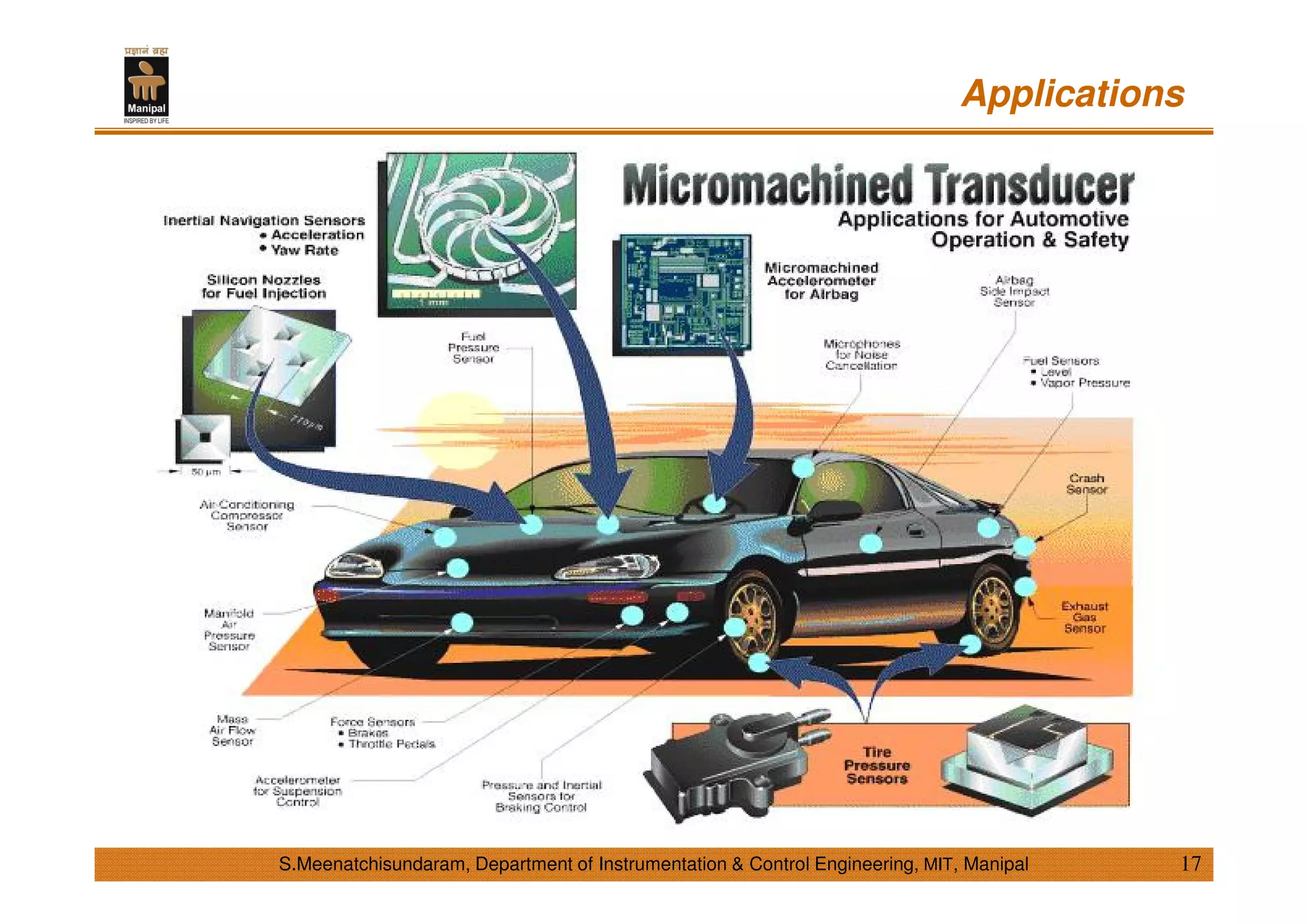

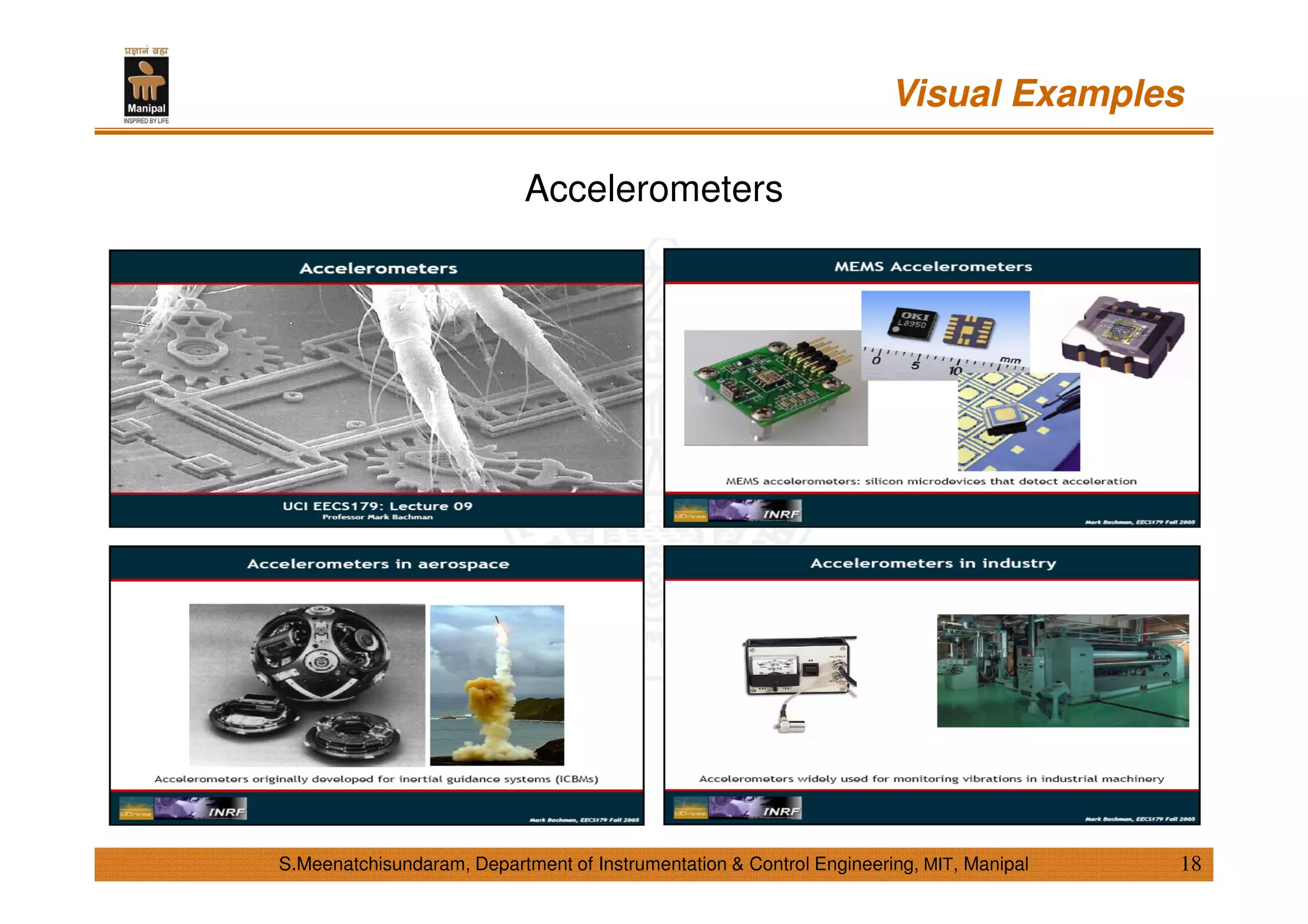

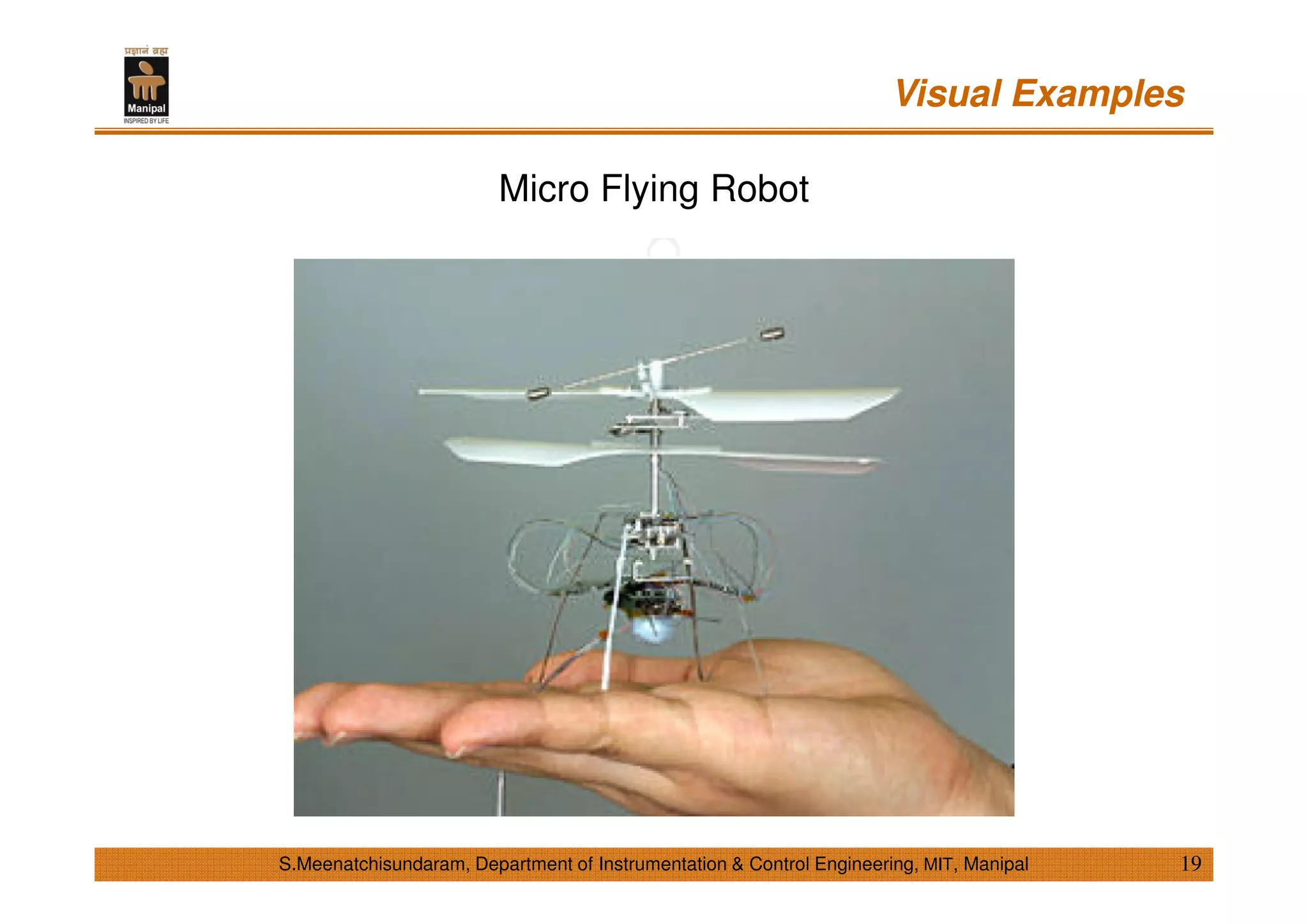

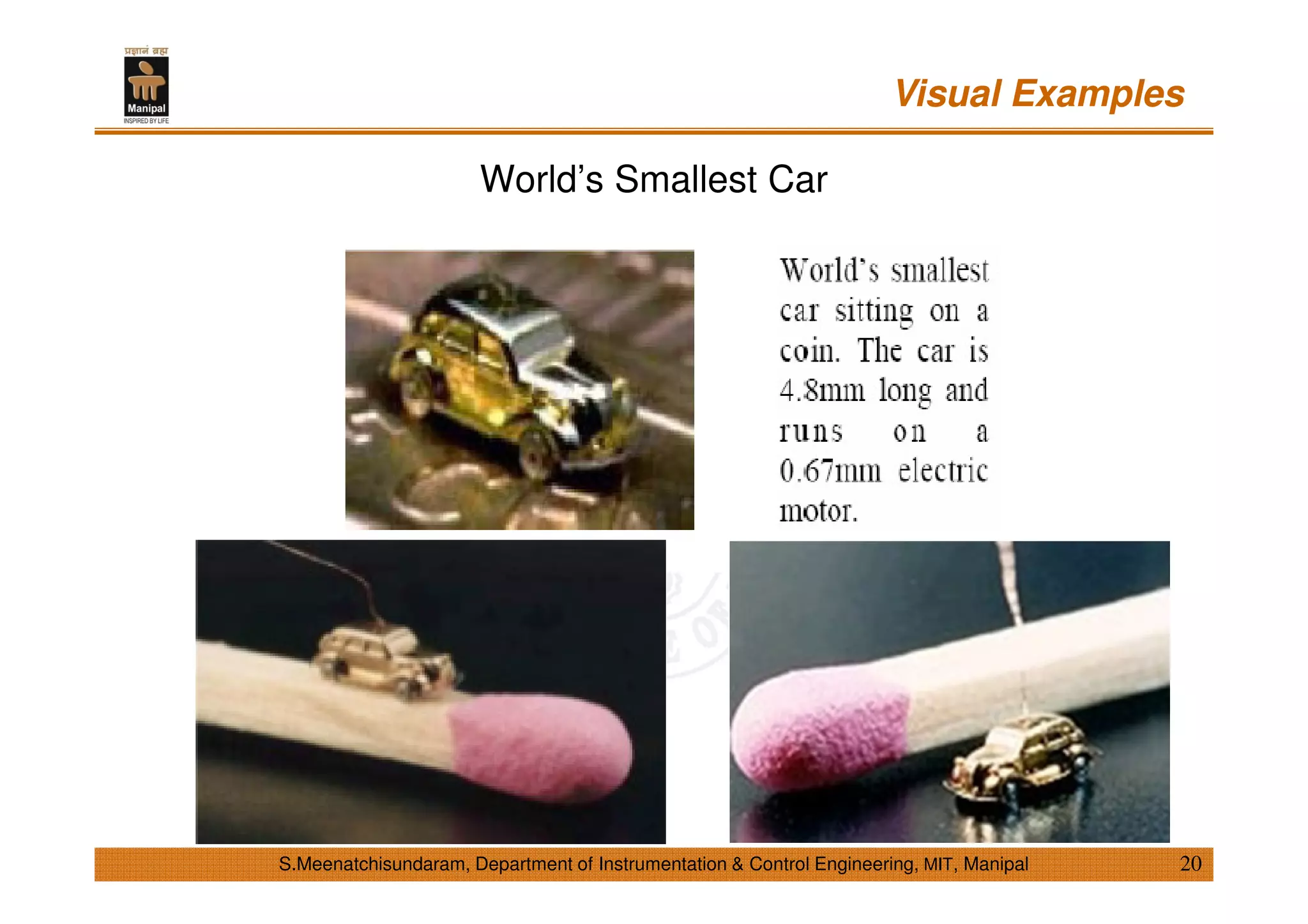

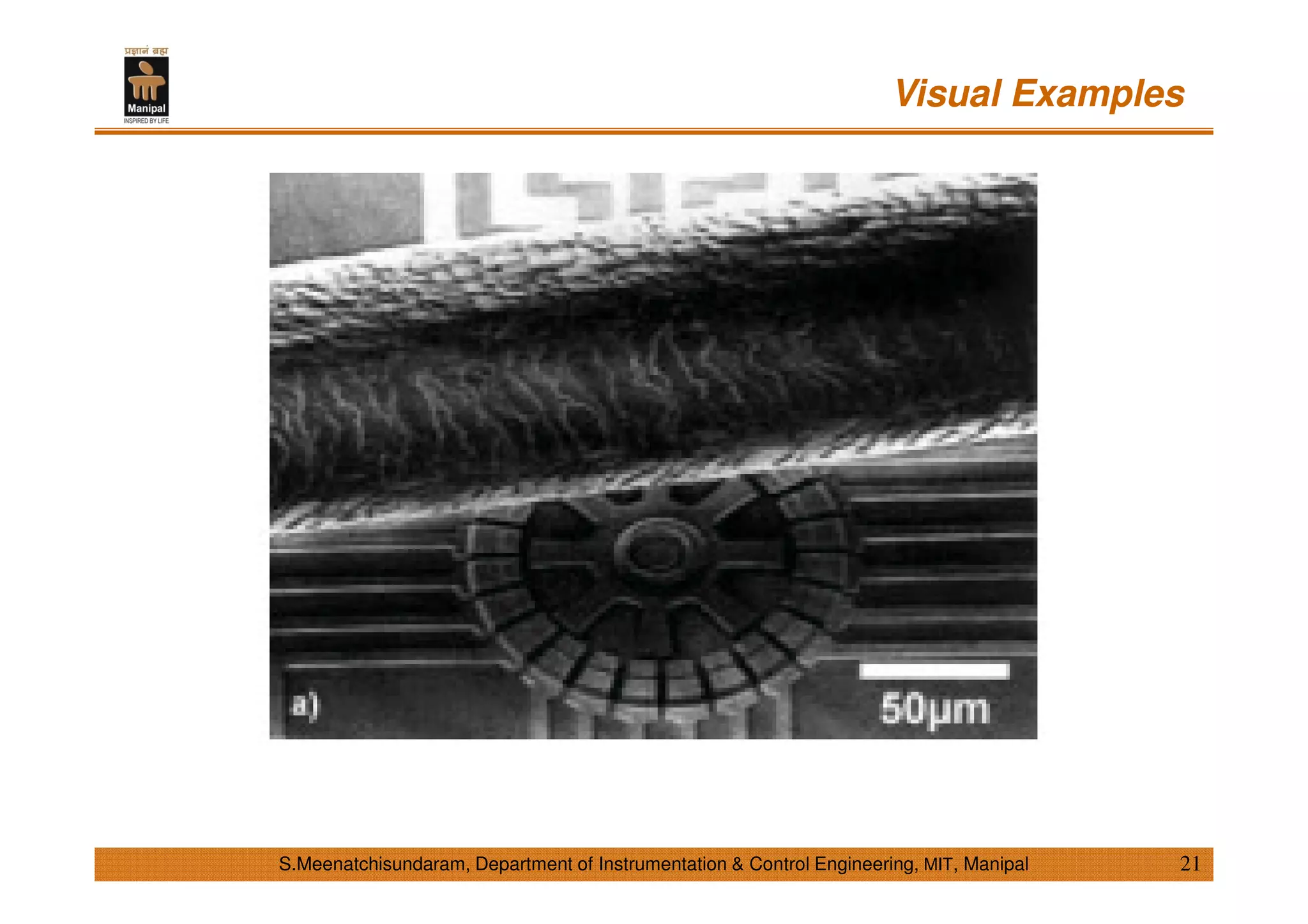

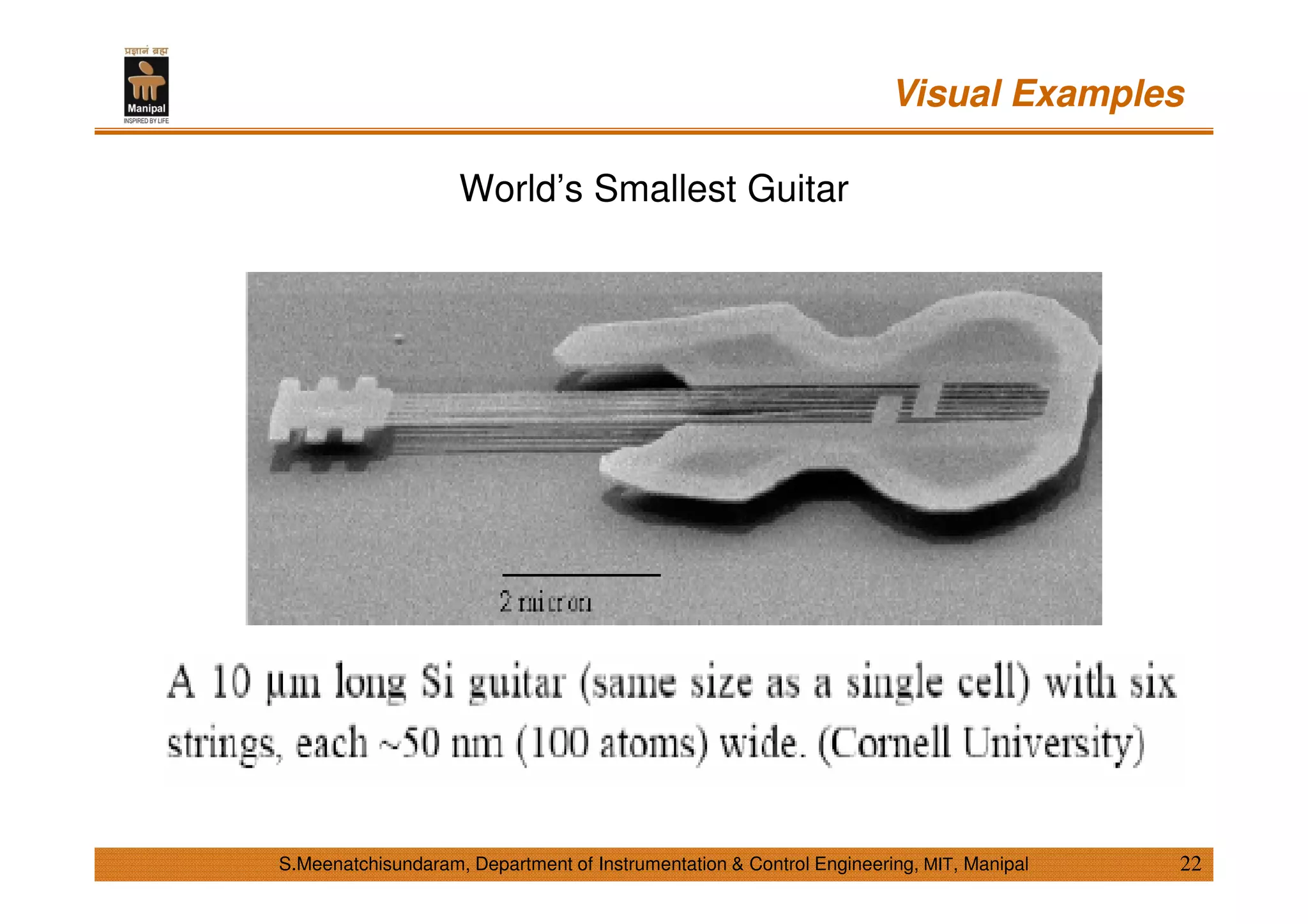

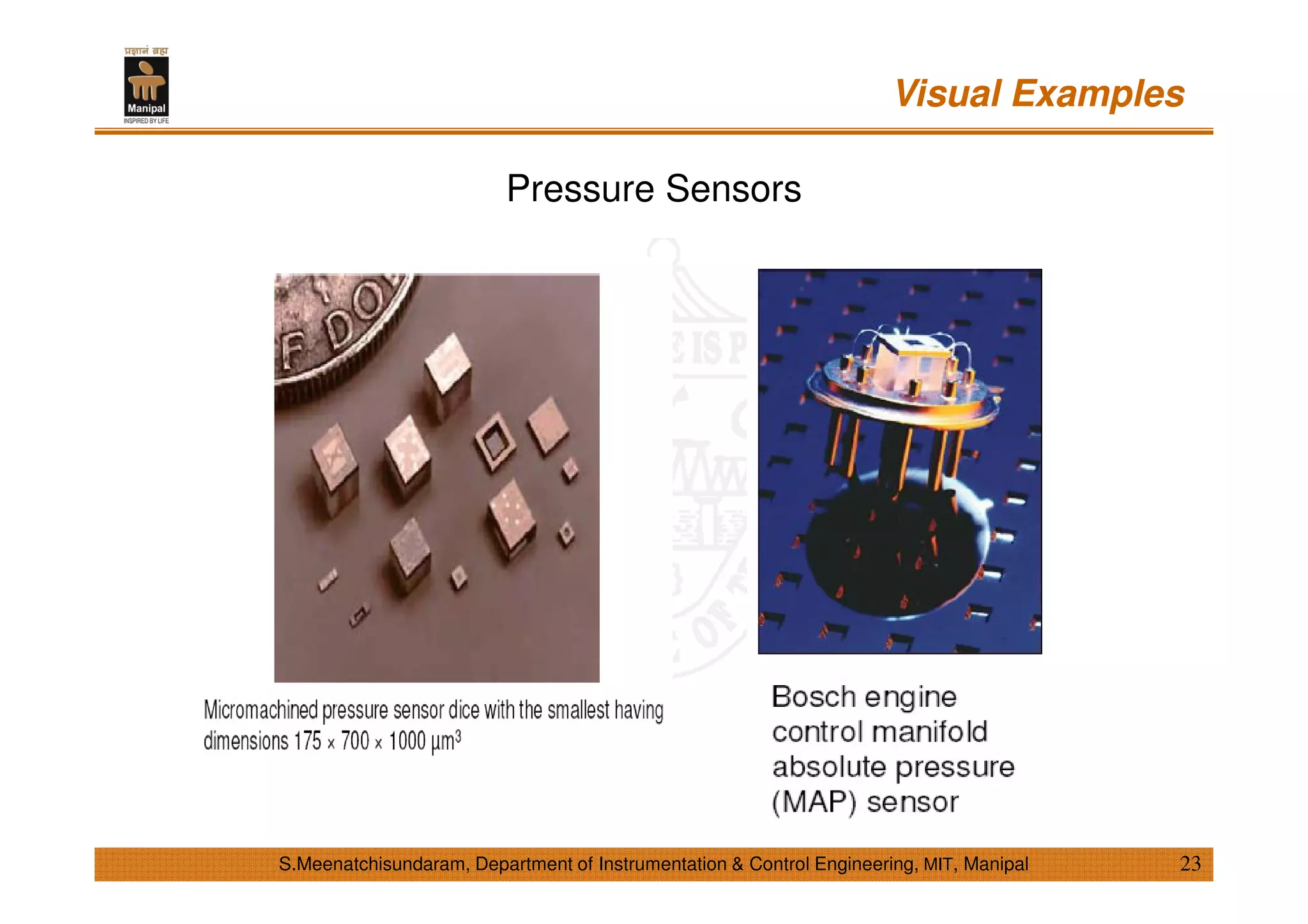

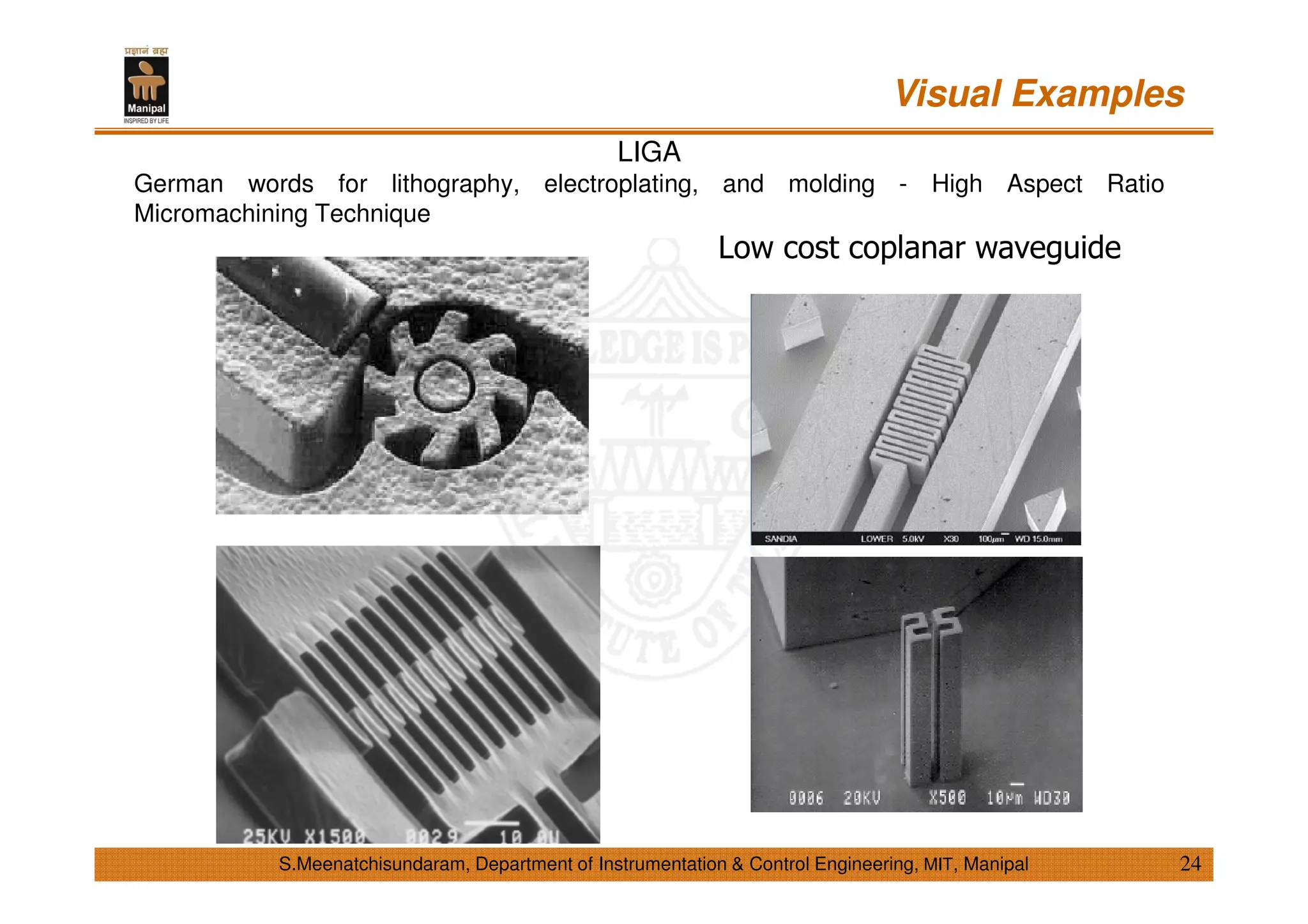

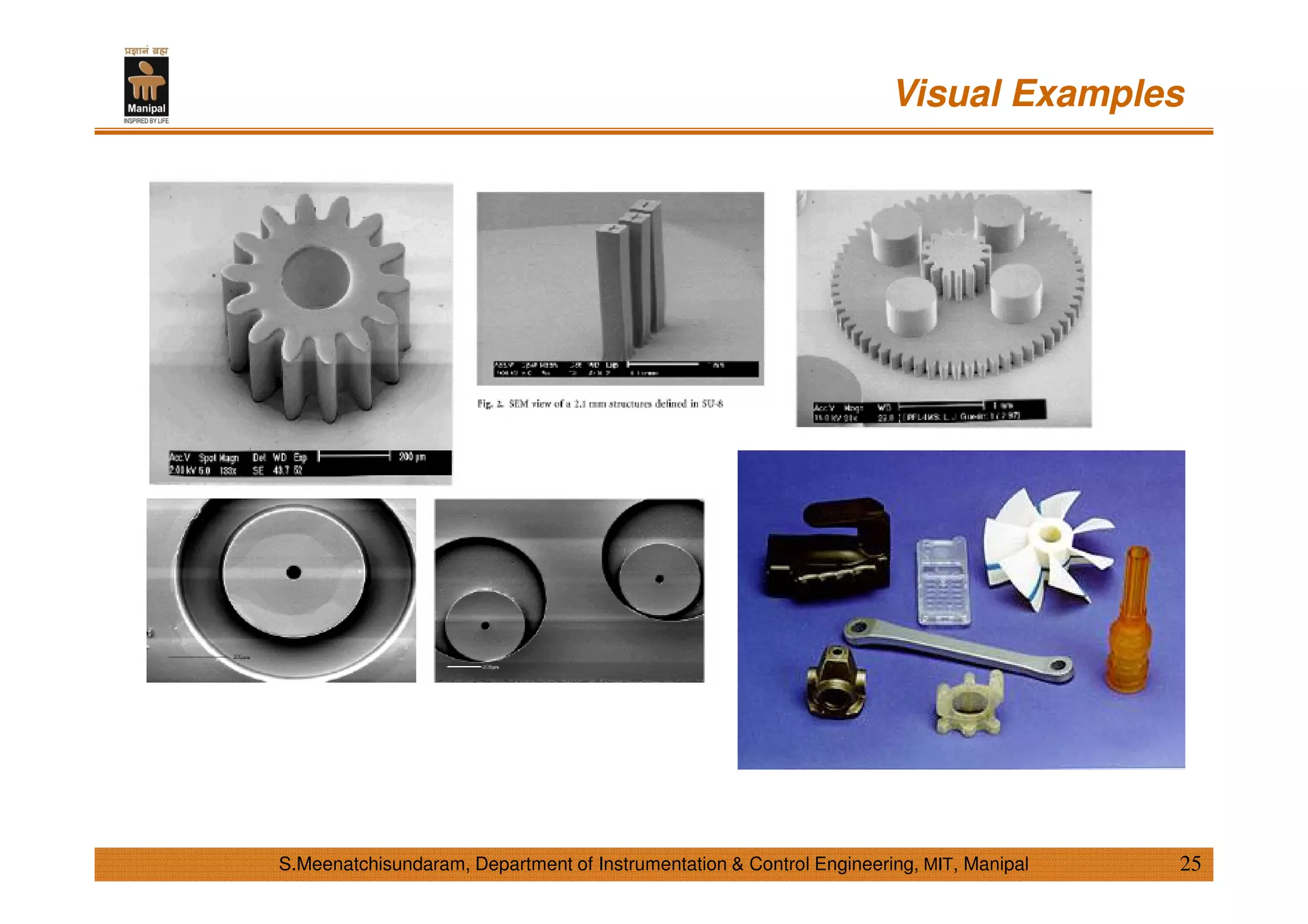

This document provides an overview of microelectromechanical systems (MEMS). It discusses the advantages of MEMS such as small size, low cost, and precision movement. Examples of applications are given in industries like automotive, healthcare, aerospace, and consumer products. Limitations of MEMS like friction and heat dissipation are also outlined. Visual examples of MEMS devices like accelerometers, micro robots, and pressure sensors are presented.