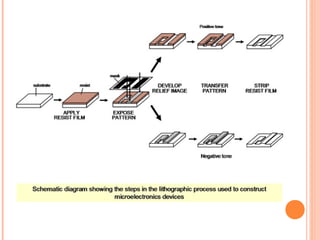

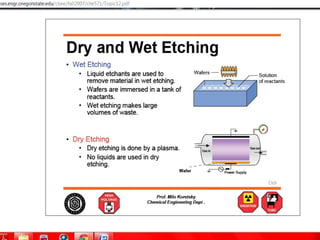

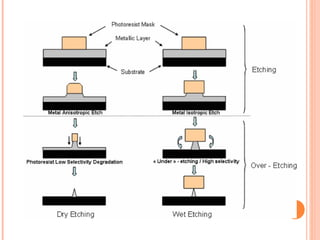

This document discusses microelectromechanical systems (MEMS) fabrication methods. It covers common MEMS fabrication processes like deposition, lithography, and etching. Deposition methods include chemical vapor deposition and physical vapor deposition to deposit thin films. Lithography involves transferring patterns to photosensitive materials using masks and radiation exposure. Etching is used to selectively remove materials, including wet etching using chemicals and dry etching using reactive ions. The document also discusses challenges with MEMS packaging, limited prototyping and manufacturing options, and the need for improved design tools.