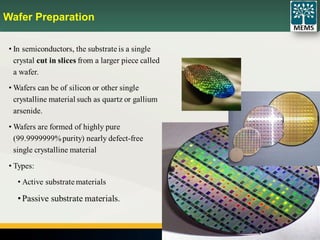

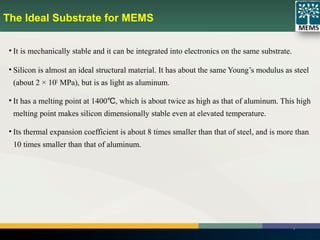

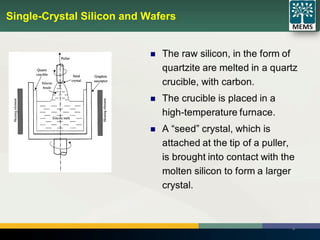

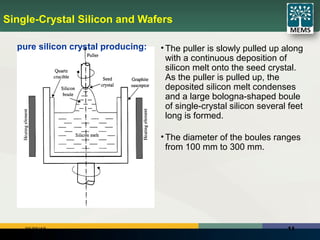

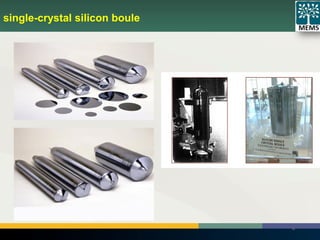

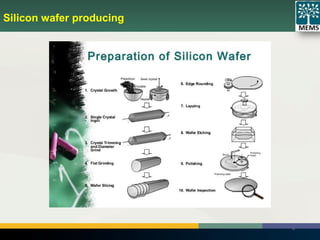

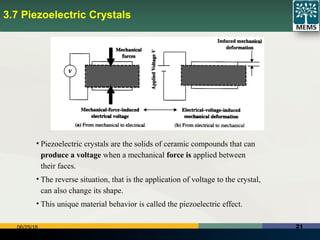

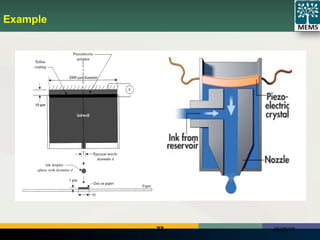

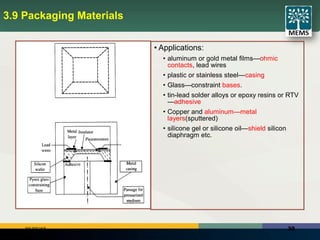

This document discusses materials used for MEMS and microsystems, including substrates, active materials, and packaging materials. Common substrate materials include silicon, quartz, and various polymers. Silicon is discussed in detail due to its ideal properties as a substrate. Other materials covered include silicon compounds, piezoelectric crystals, and conductive polymers. The document concludes with a brief overview of packaging materials and methods.