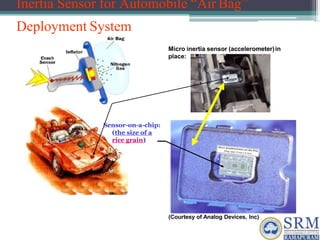

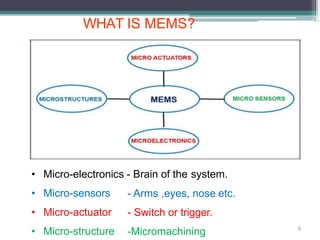

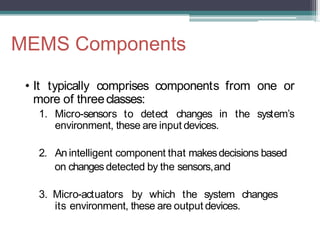

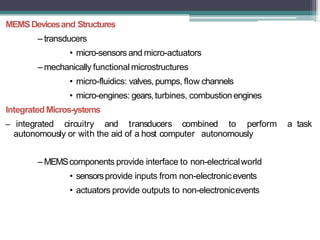

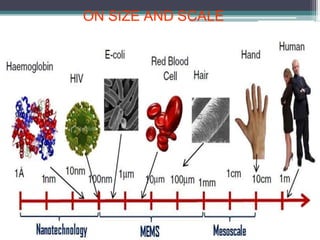

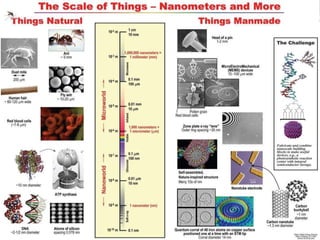

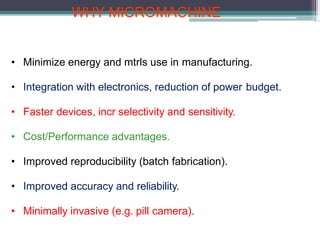

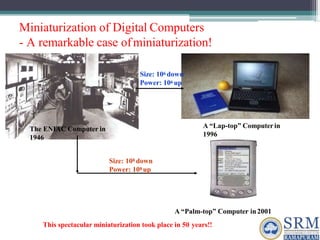

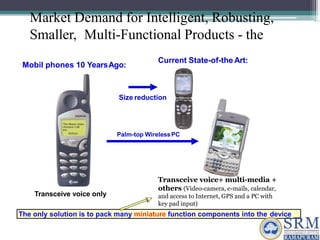

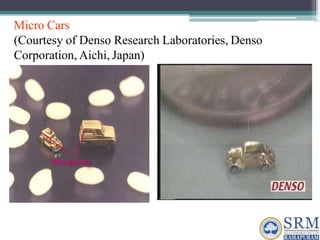

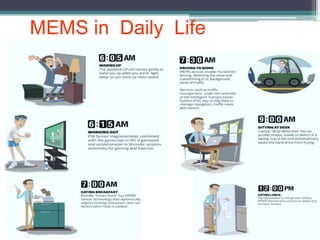

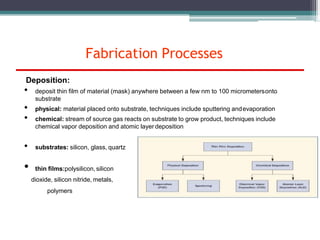

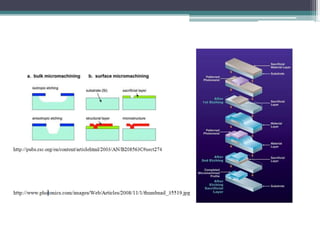

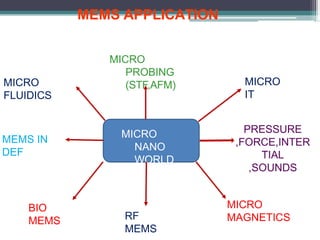

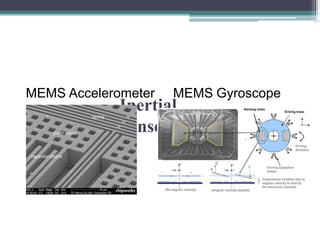

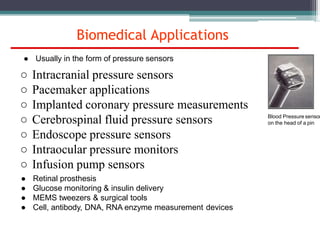

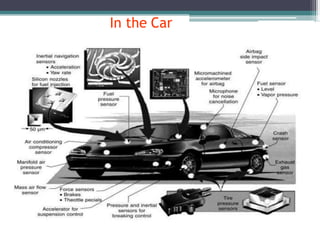

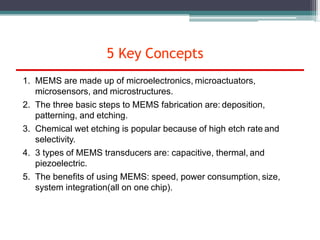

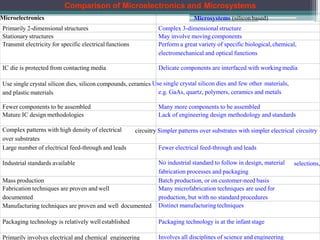

This document provides an introduction to microelectromechanical systems (MEMS). It defines MEMS as systems that combine electrical and mechanical components on the micrometer scale to sense and control the physical world. MEMS components include microsensors to detect environmental changes, an intelligent component to make decisions based on sensor input, and microactuators to change the environment based on the decisions. Common MEMS applications include accelerometers, inkjet printer heads, medical devices, and sensors in automobiles. The document discusses fabrication techniques like deposition, patterning, and etching used to create MEMS, as well as their advantages like low cost, small size, and high functionality.