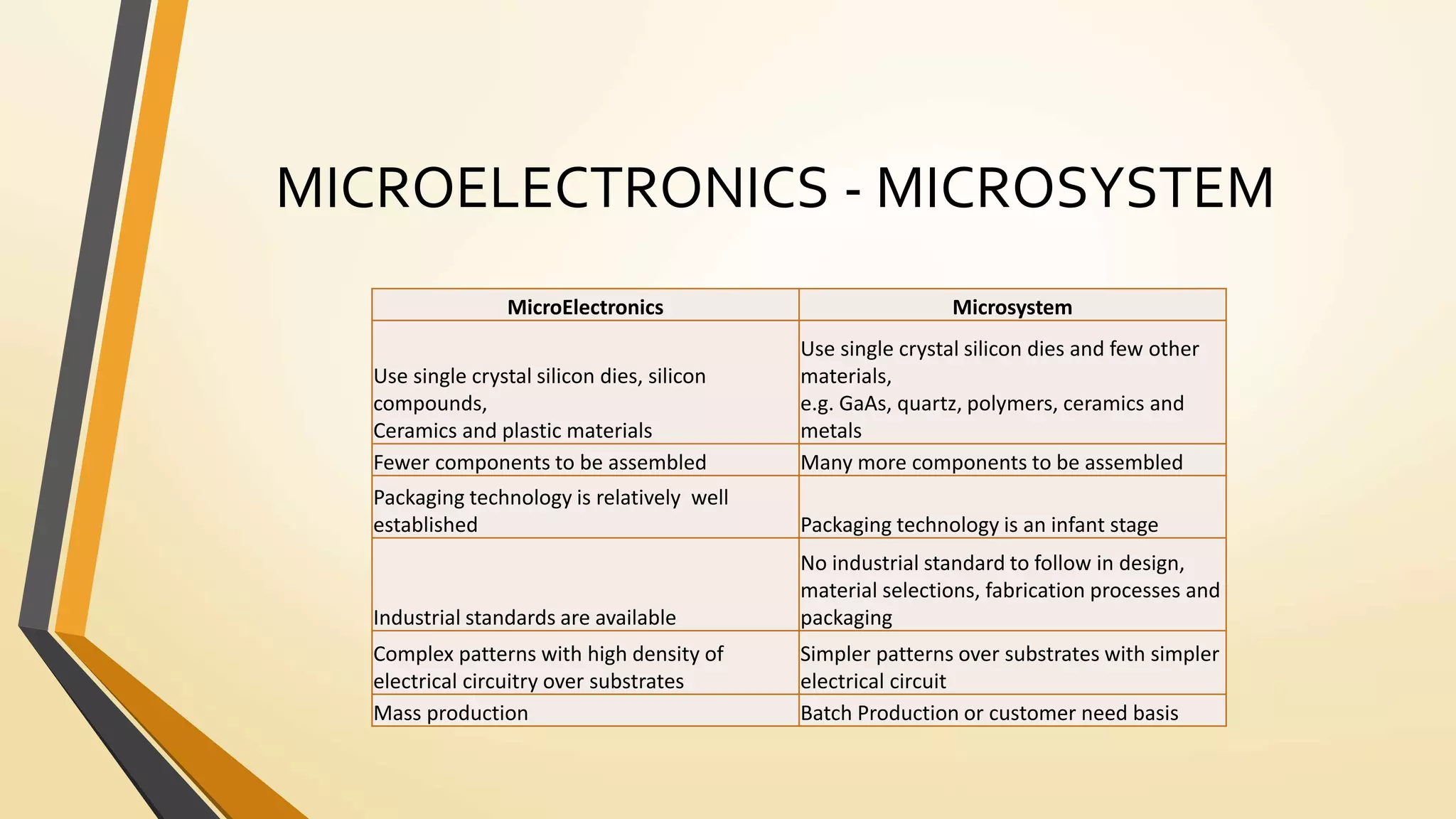

This document discusses MEMS packaging at different levels. It describes microelectronic packaging as providing mechanical support, electrical connections and protection from environmental threats for integrated circuits. There are 5 levels of microelectronic packaging from the silicon chip to larger systems. MEMS and microsystem packaging aims to protect delicate core elements from mechanical or environmental damage during operation. Proper packaging design considers costs, environmental effects, reliability and achieving minimum electrical connections to prevent failures.