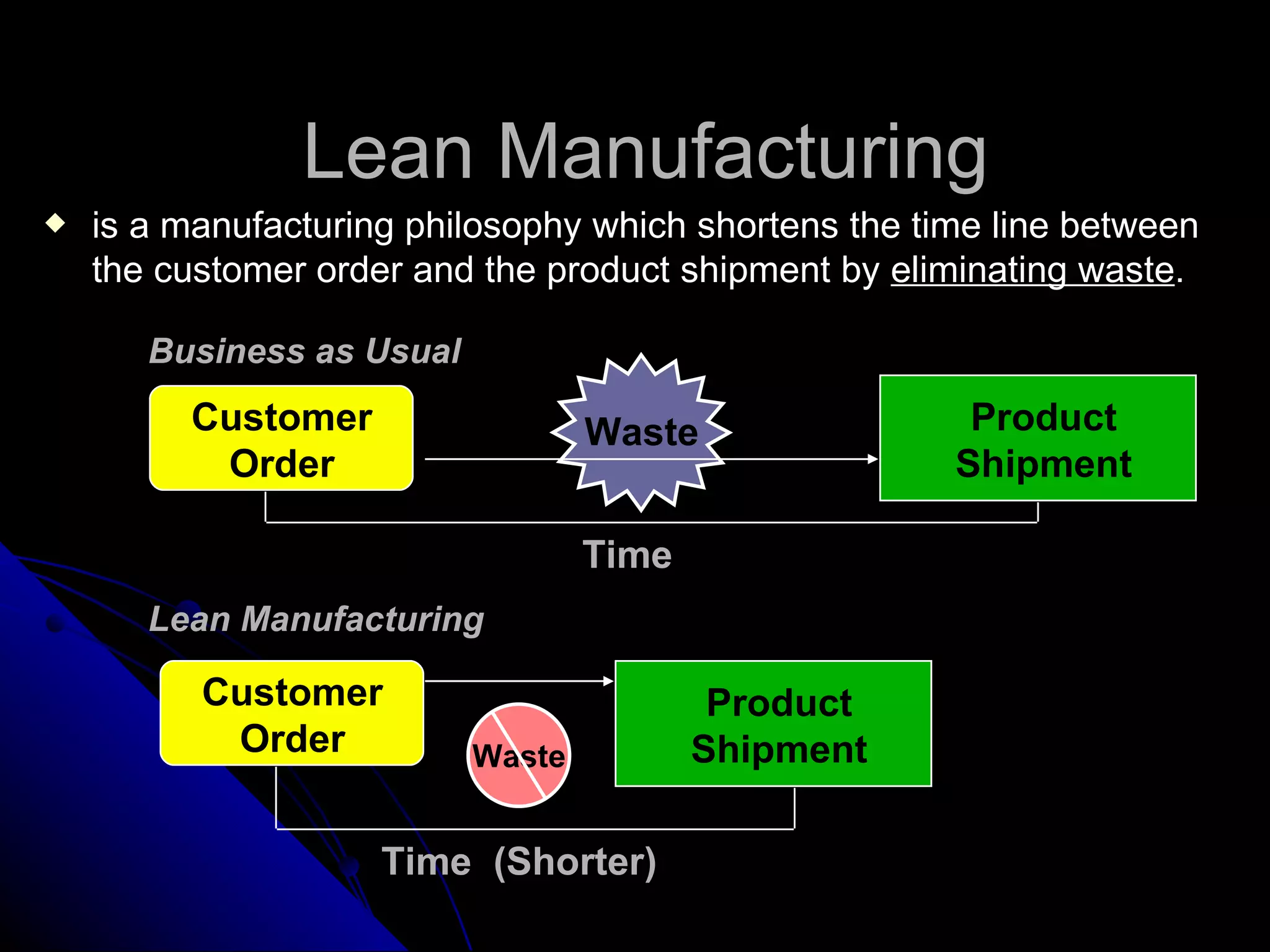

The document provides an overview of lean manufacturing concepts, including:

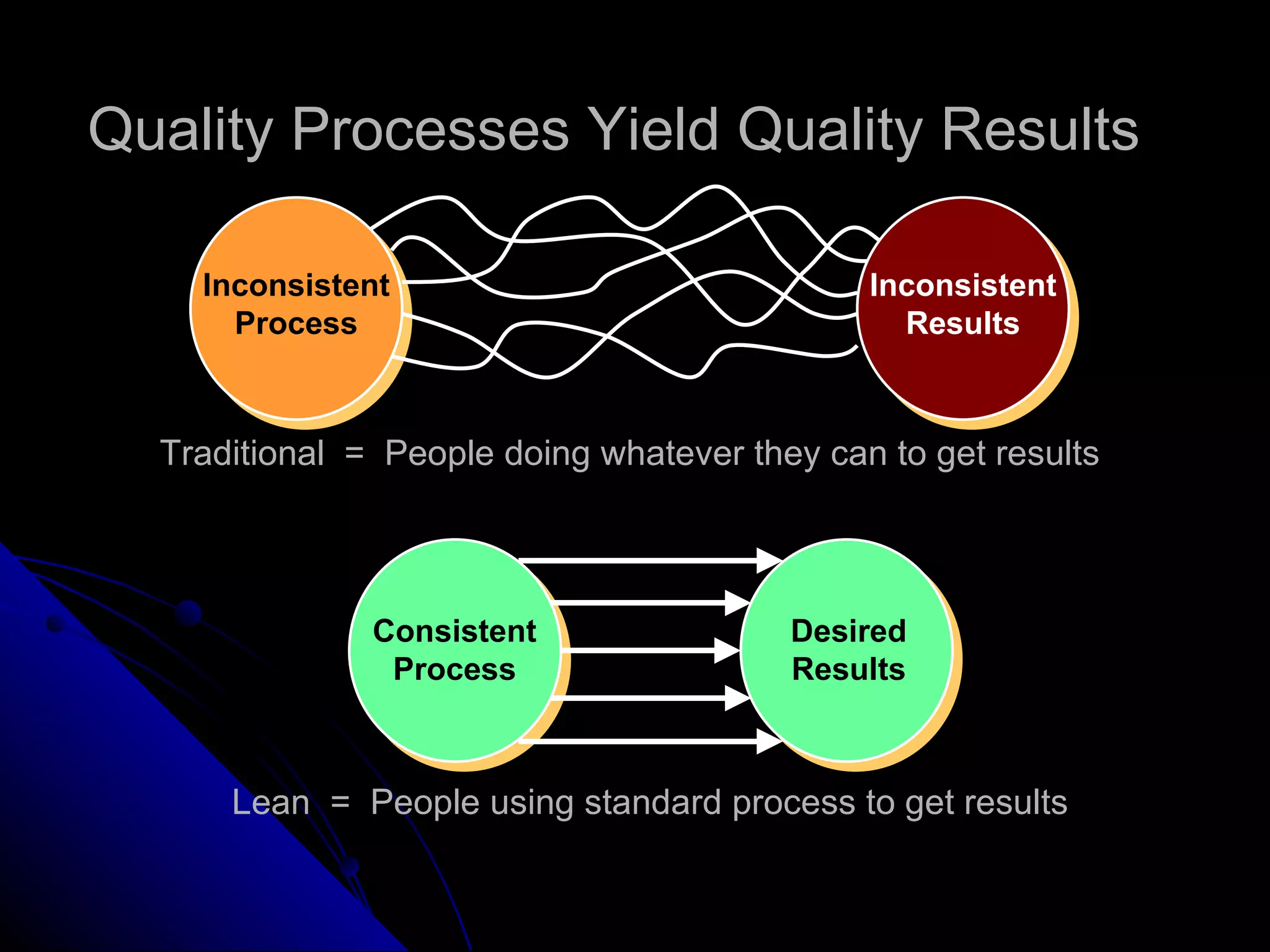

- Distinguishing between mass and lean manufacturing approaches.

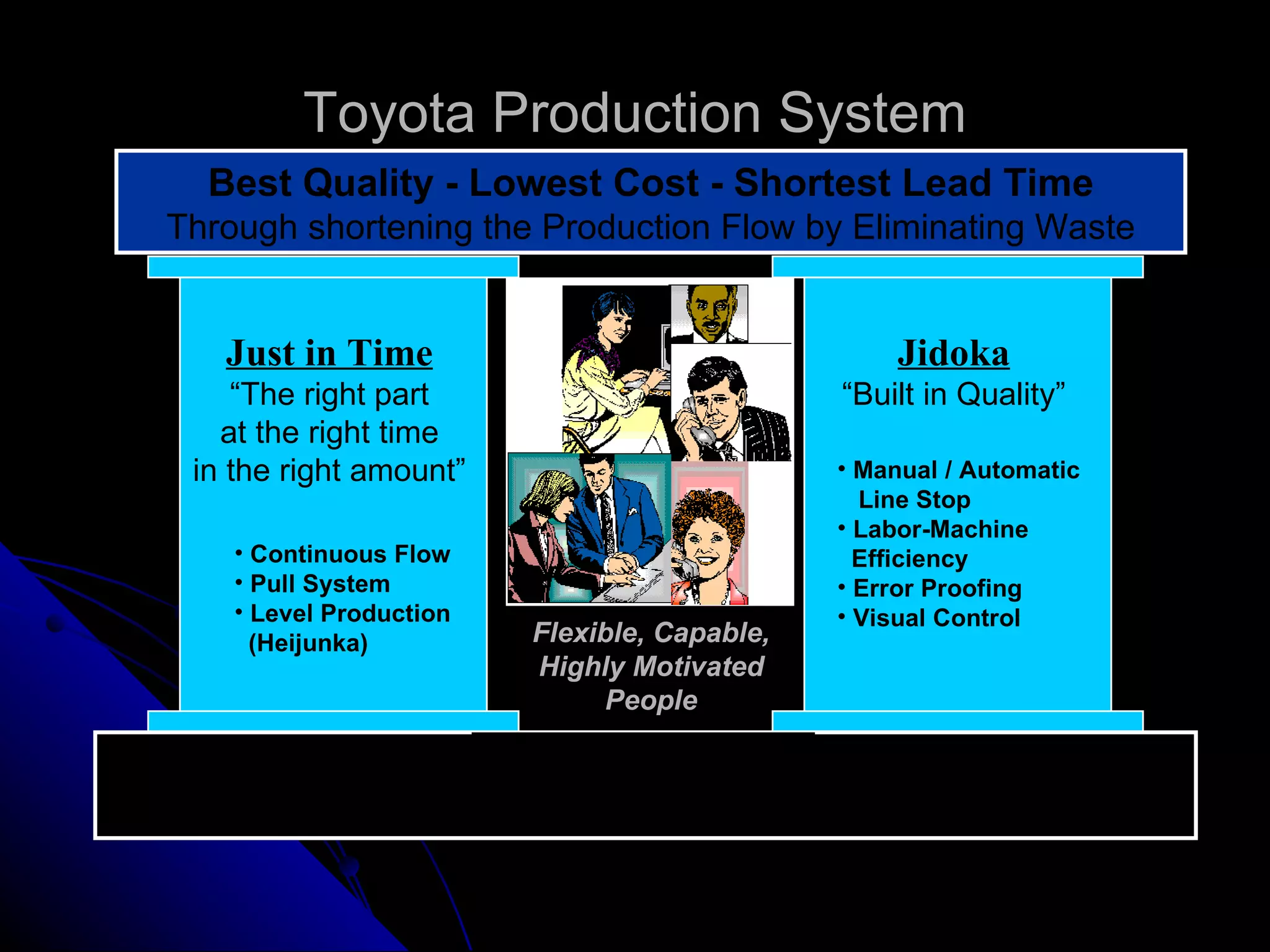

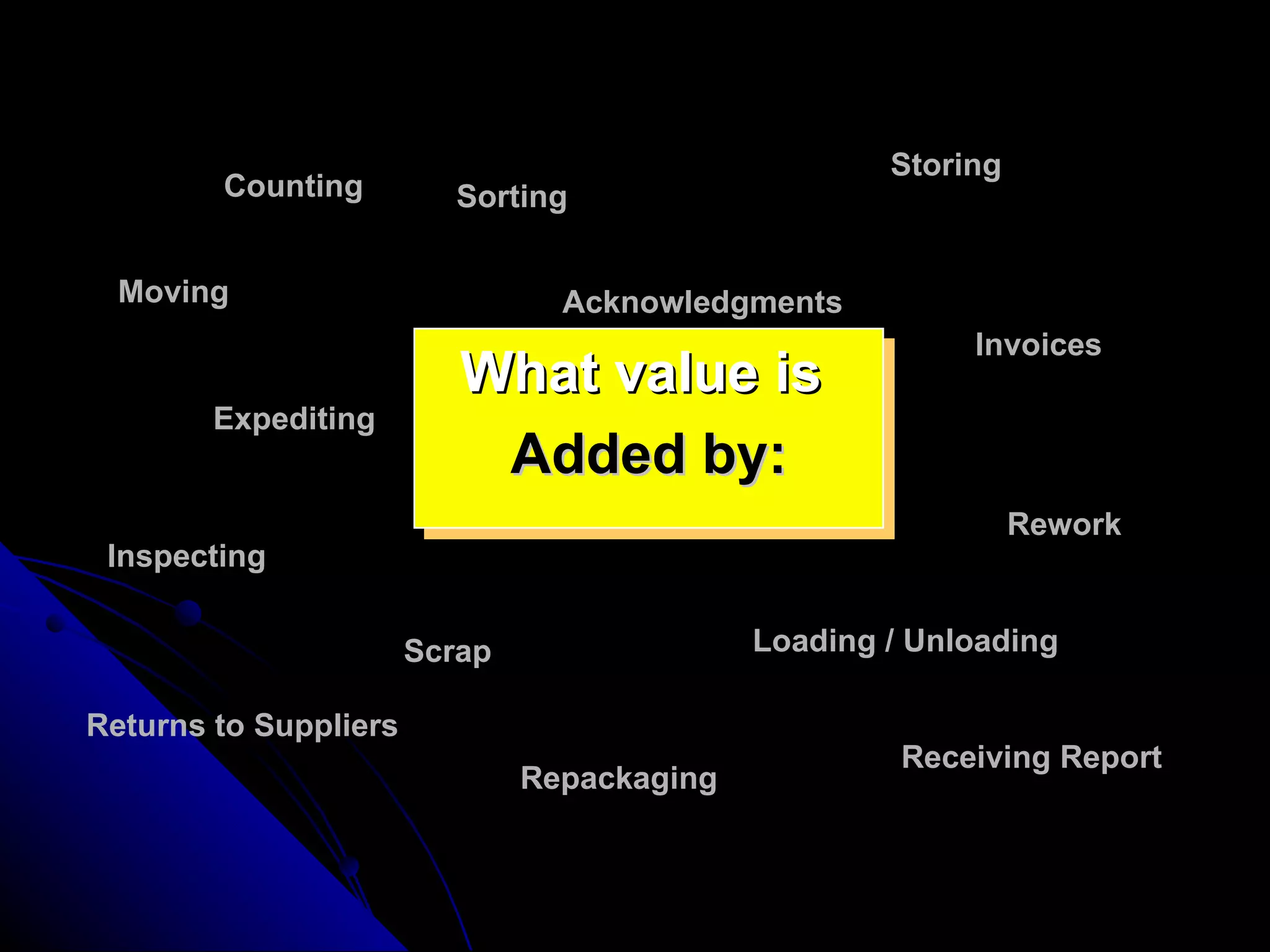

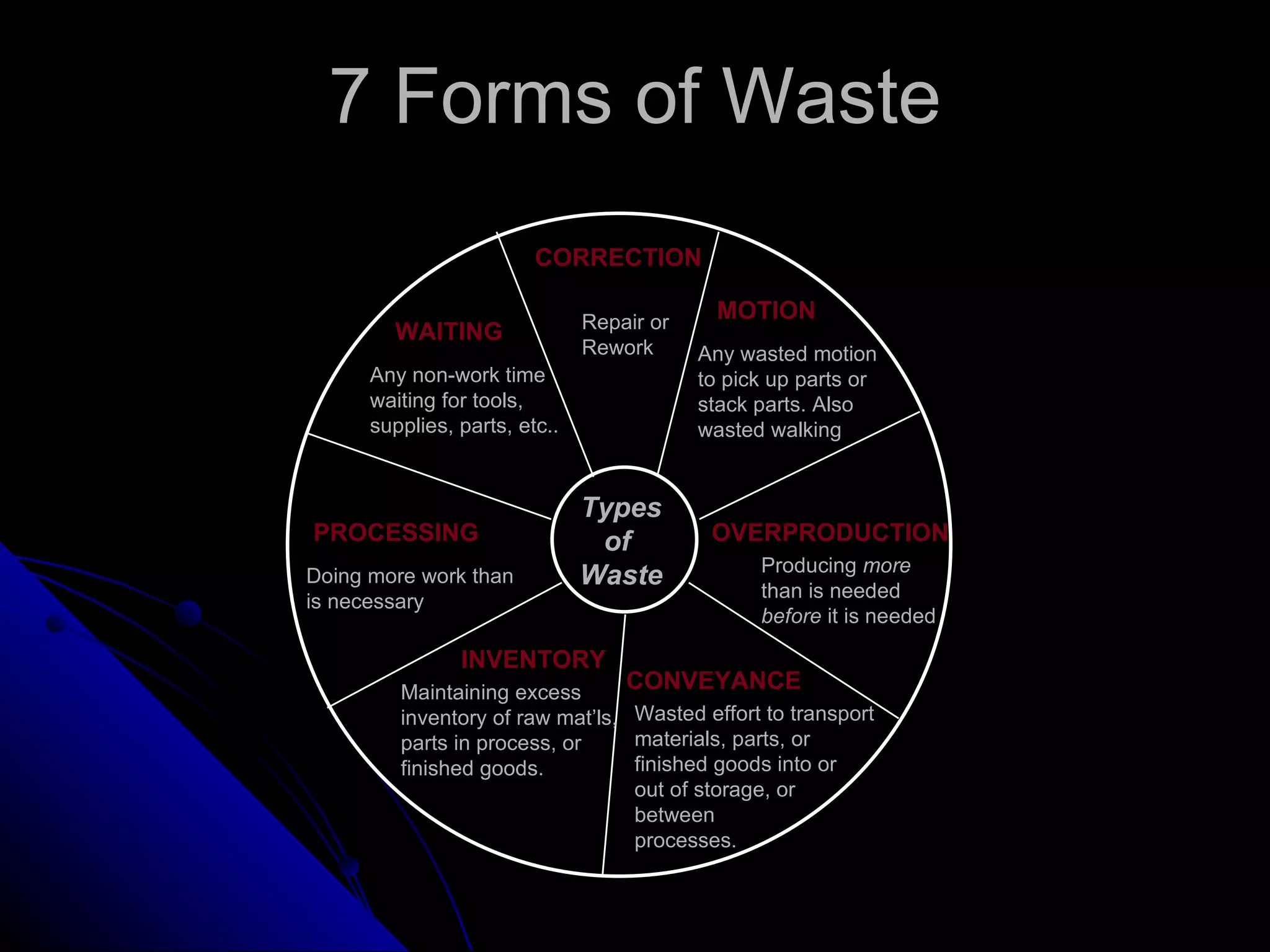

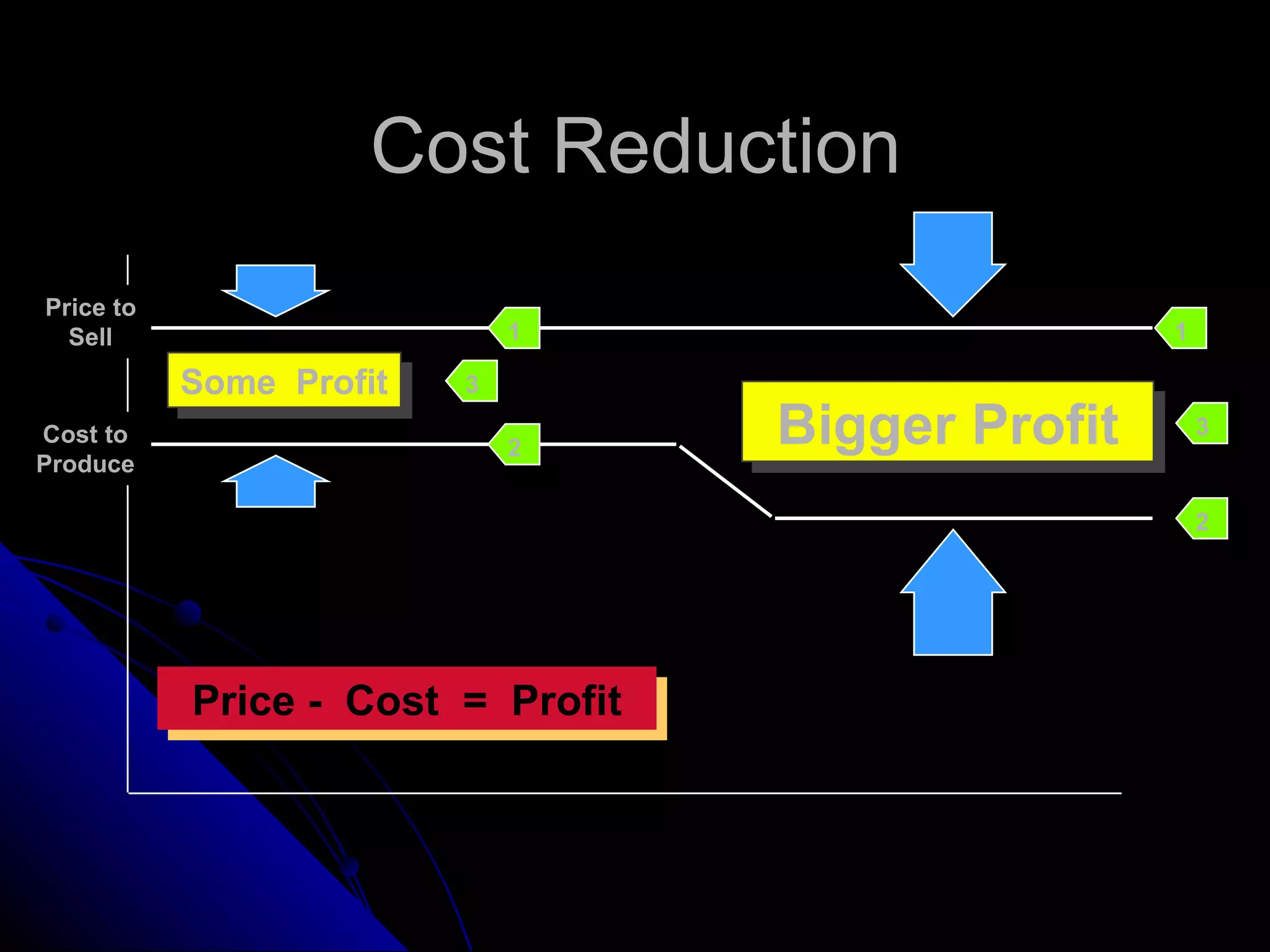

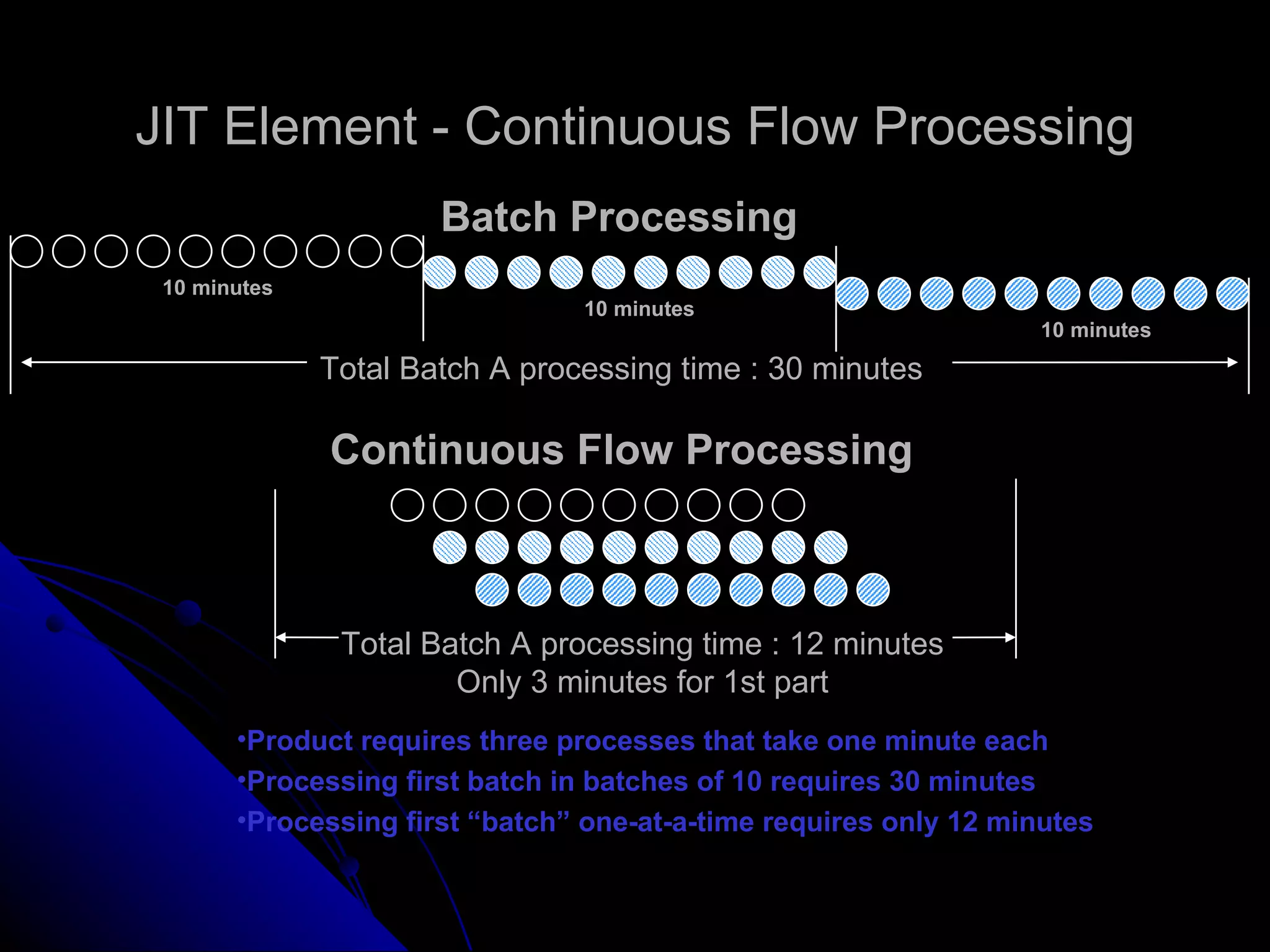

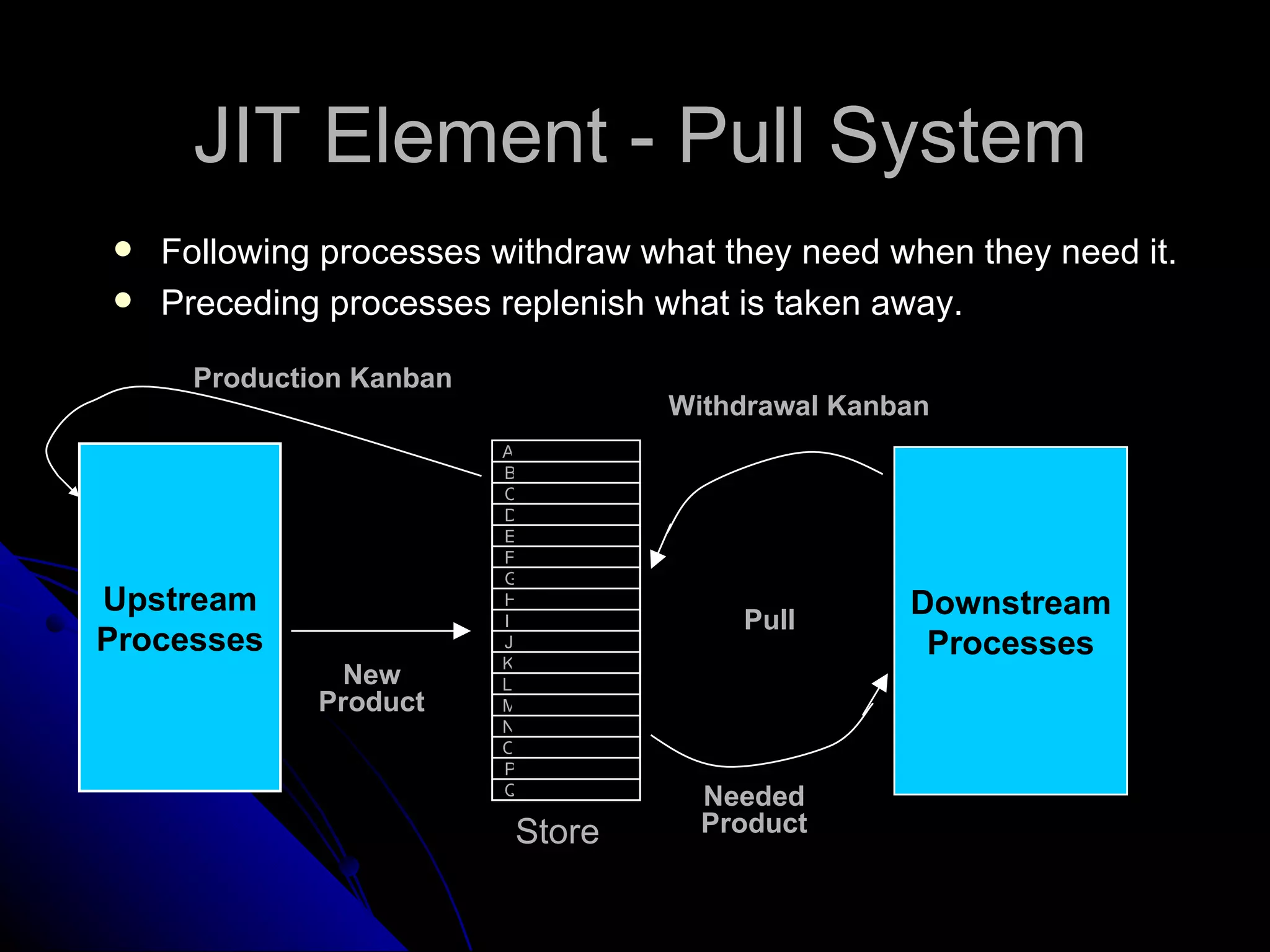

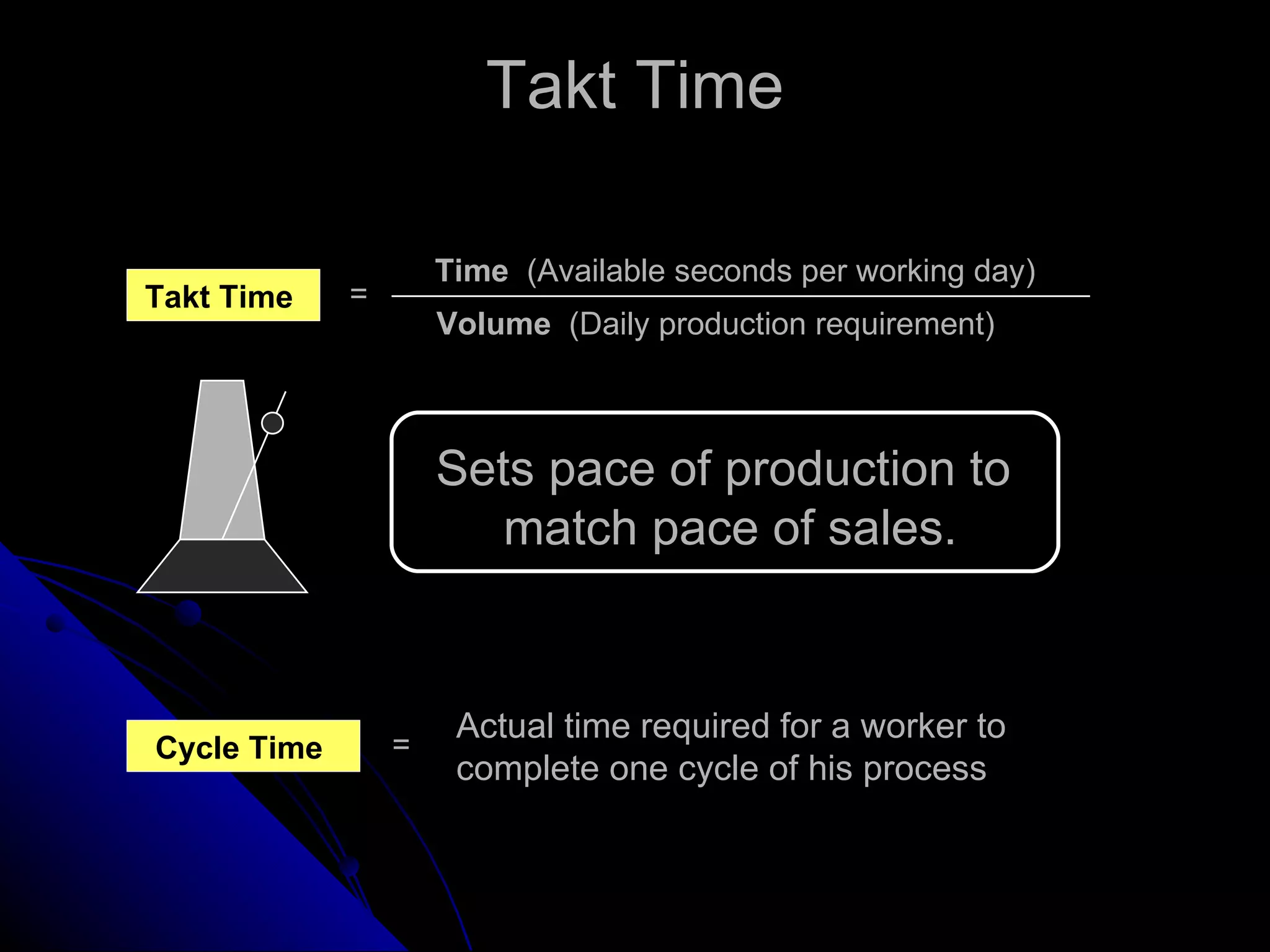

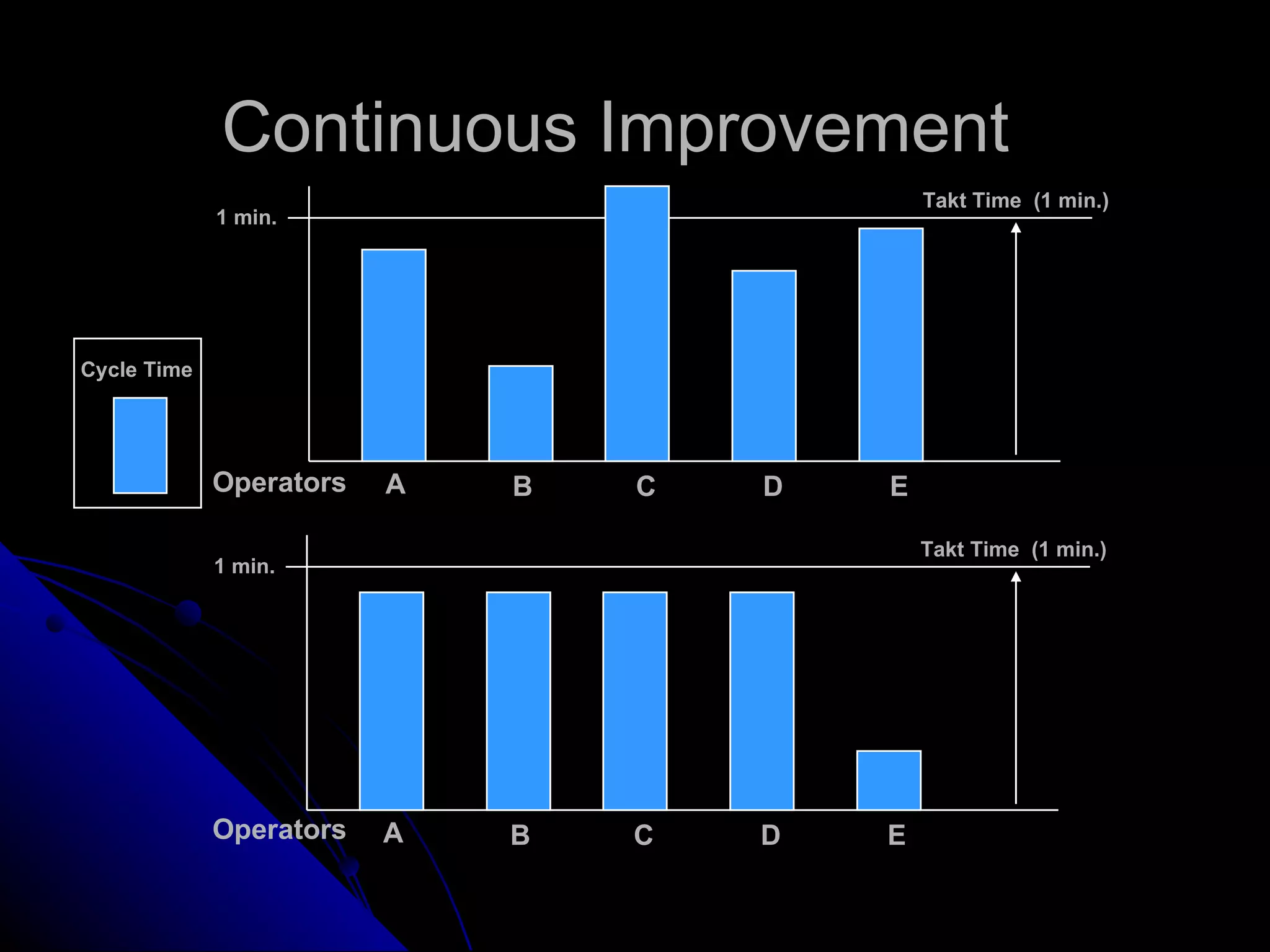

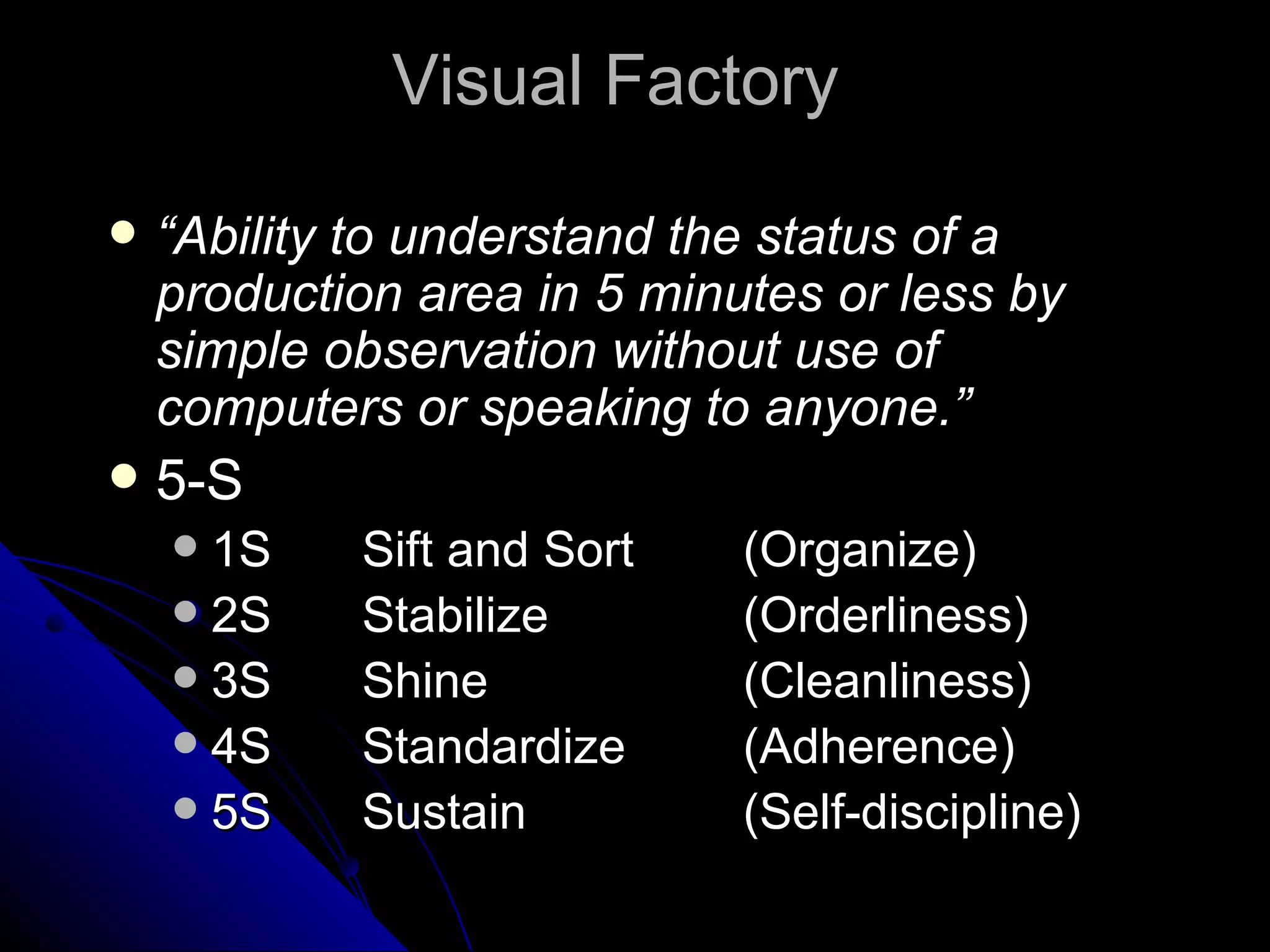

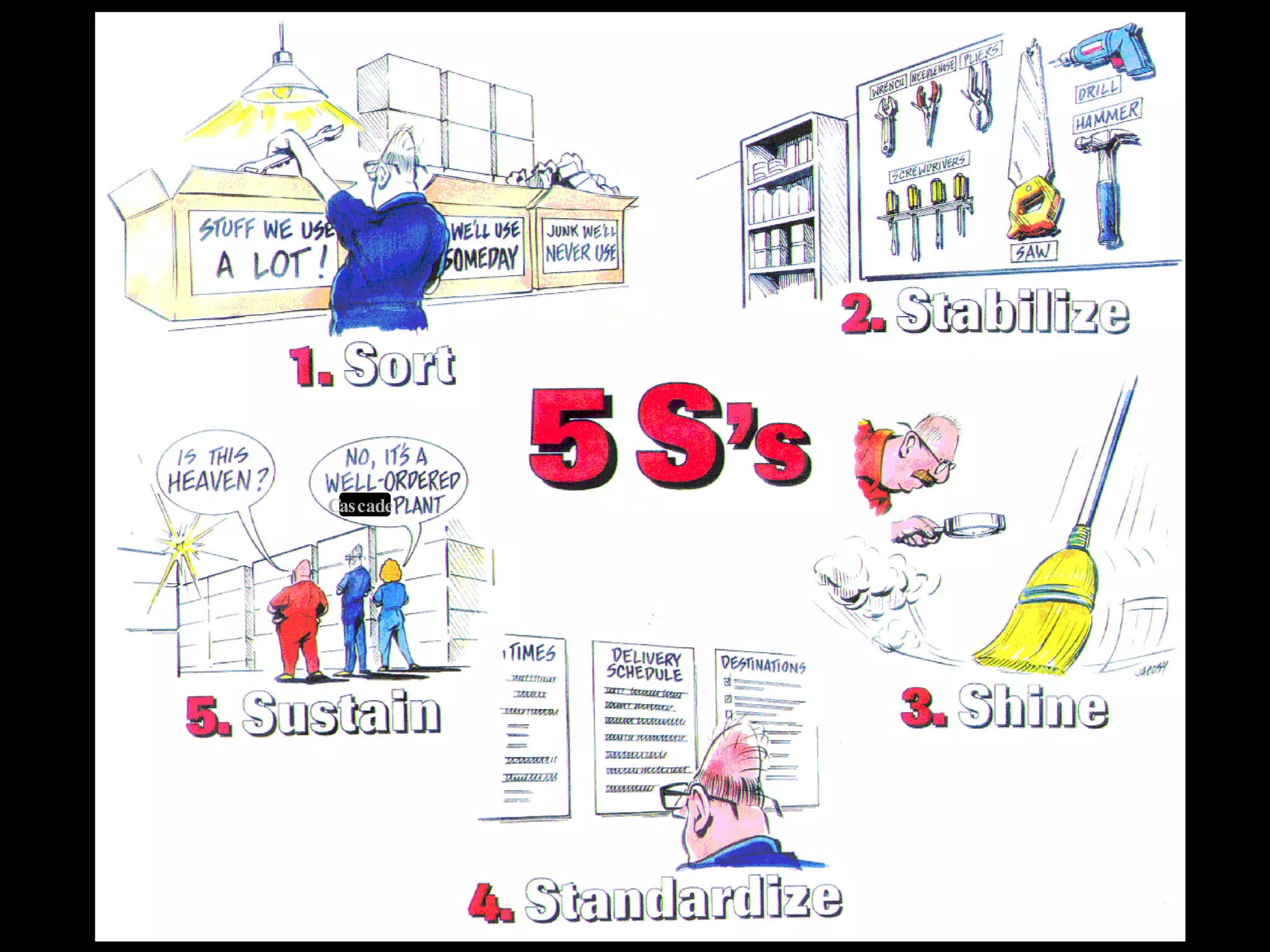

- Key concepts of lean manufacturing including eliminating waste, just-in-time production, continuous flow, and visual management techniques.

- The goals of a lean transformation are to reduce costs, improve quality, and shorten lead times through process improvements and engaging employees.

- A lean culture emphasizes problem solving over blame, standardized work, respect for people, and continuous improvement.