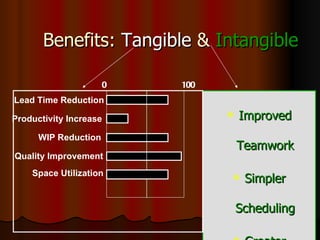

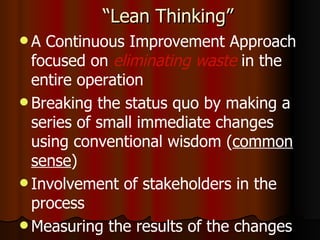

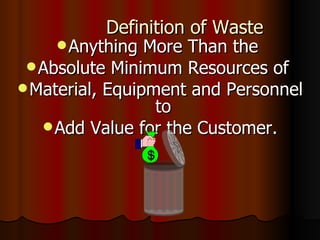

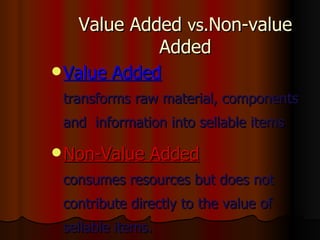

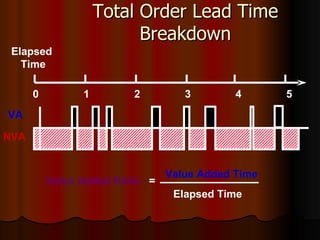

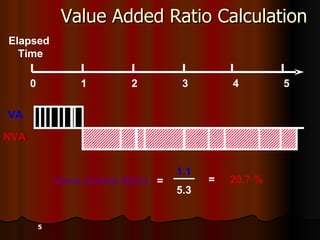

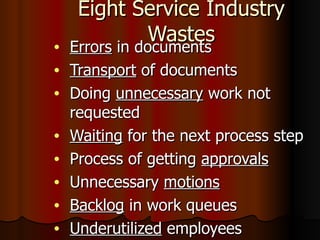

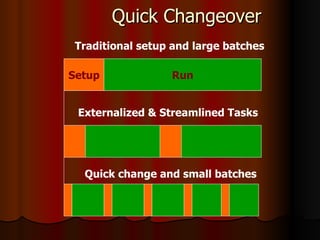

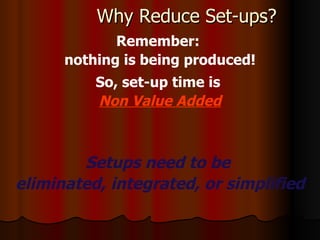

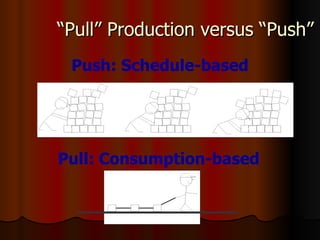

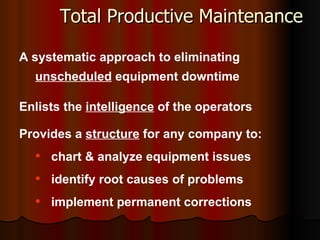

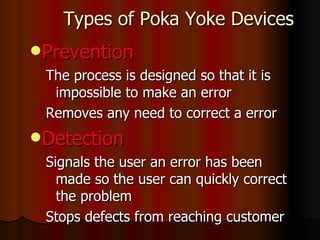

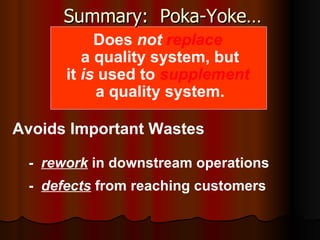

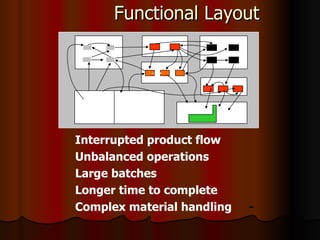

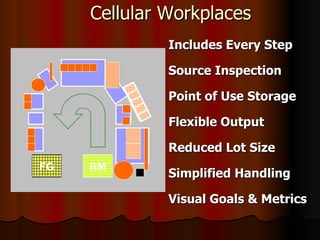

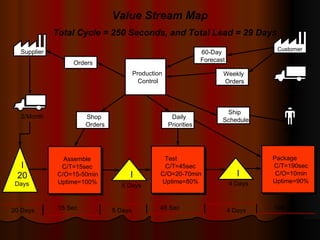

The document summarizes key concepts in lean systems and production. It discusses eliminating waste to add value for customers and improve productivity. Specific lean tools are outlined, including 5S, quick changeover, pull production, total productive maintenance, poka-yoke, cellular layouts, and value stream mapping to visualize and improve workflow. The goal is to continuously improve by removing non-value added activities, reducing lead times and inventory, and increasing throughput.