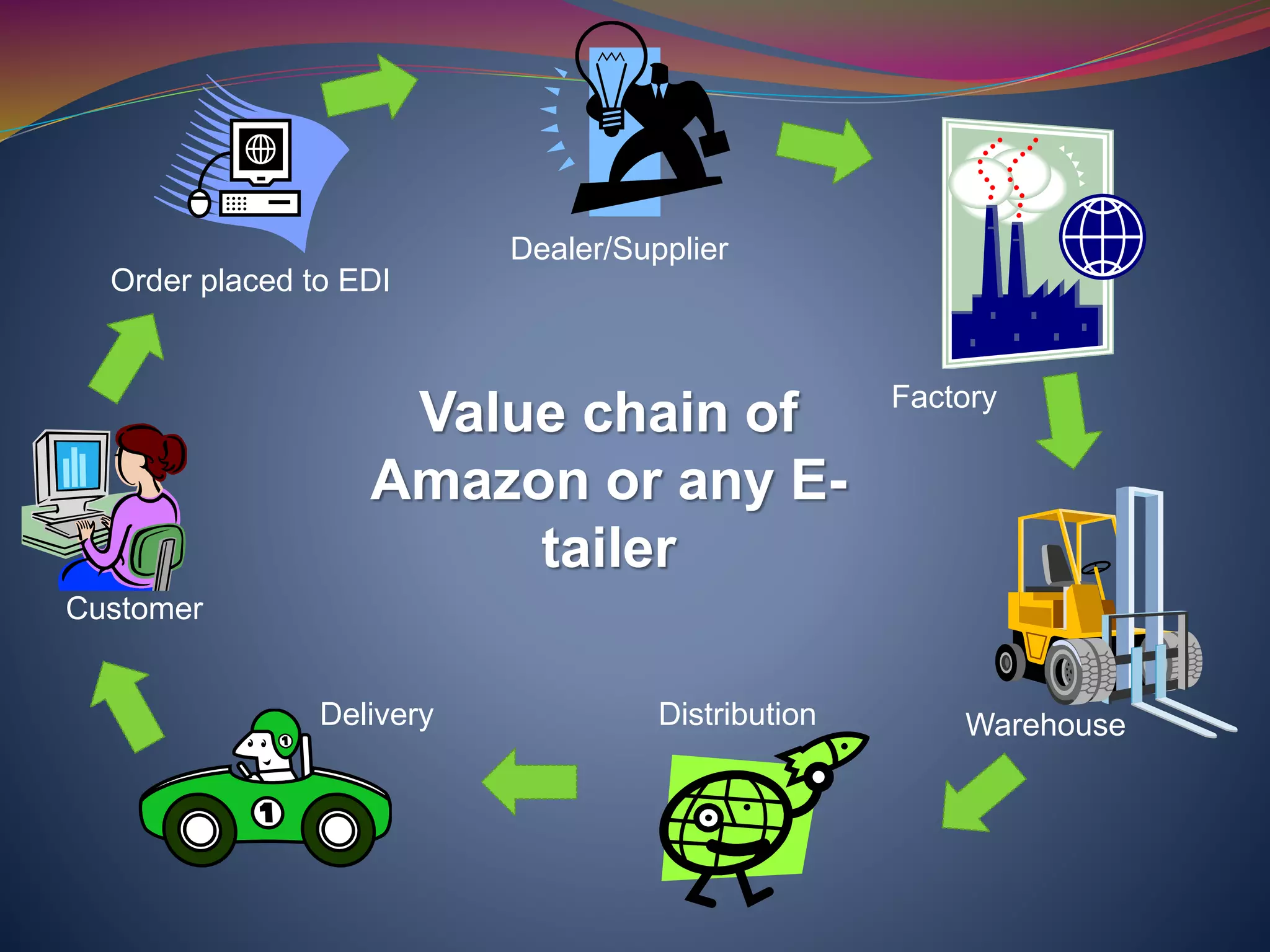

The document outlines operations management as the efficient conversion of materials and labor into goods and services to maximize organizational profit. It discusses the evolution of operations management from ancient practices to modern systems during the industrial revolution, highlighting key concepts such as planning, strategy, supply chain management, and quality control. Additionally, it explores various techniques and methodologies like Just-In-Time (JIT), project management, and different service types compared to goods.