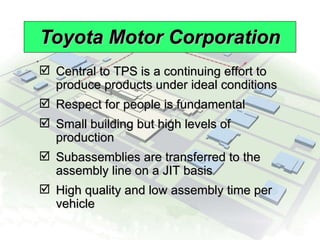

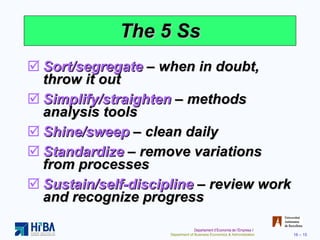

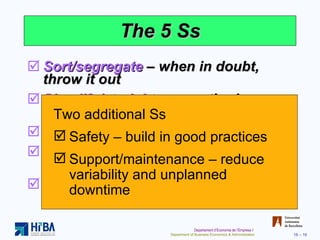

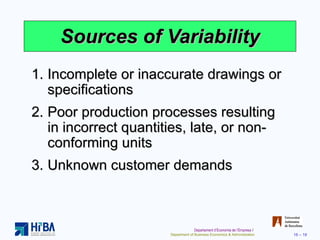

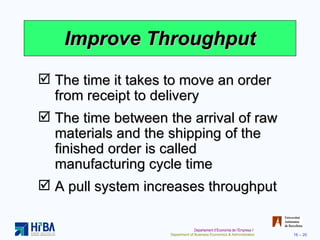

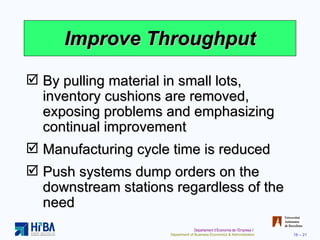

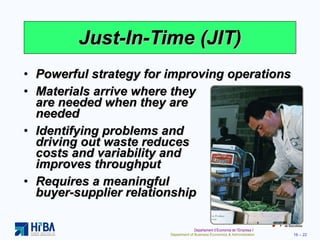

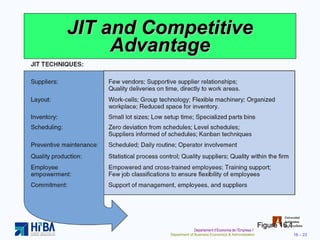

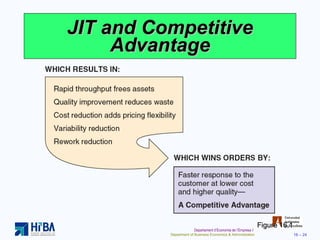

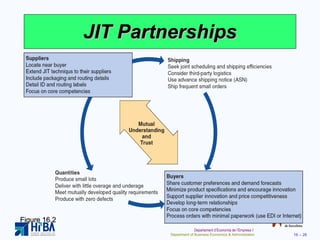

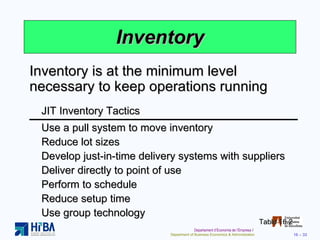

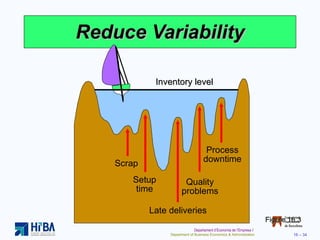

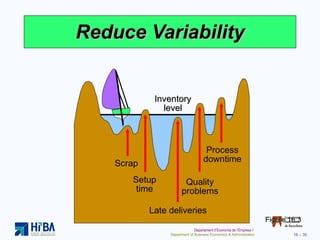

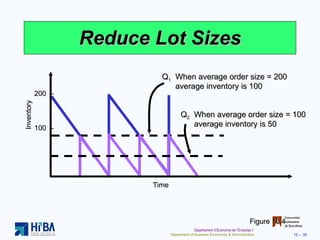

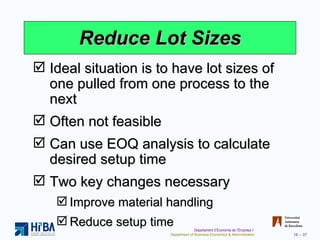

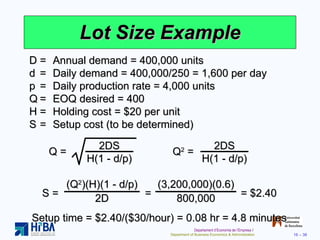

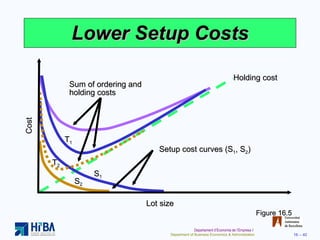

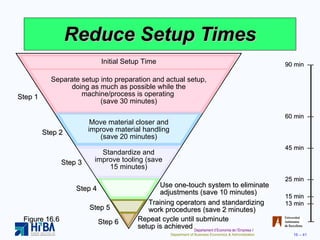

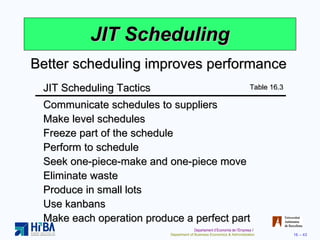

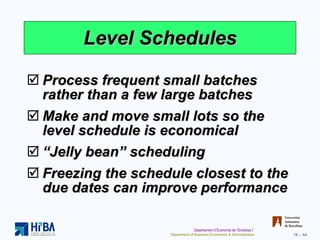

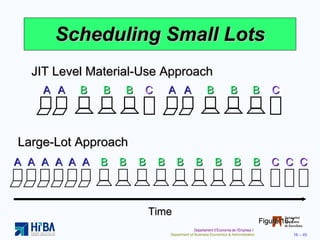

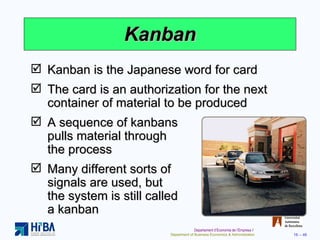

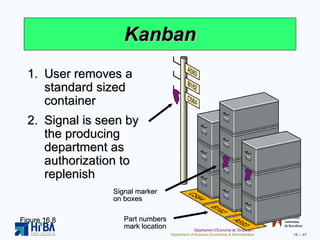

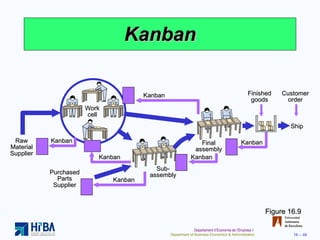

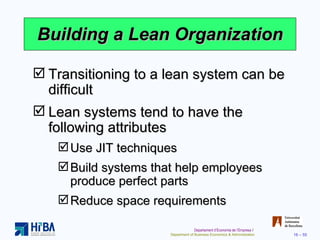

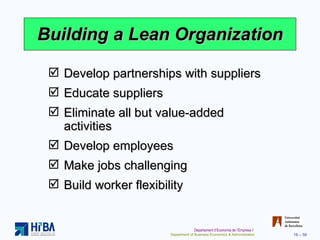

The document discusses operations management concepts related to just-in-time (JIT) and lean operations. It describes how Toyota Motor Corporation pioneered JIT and the Toyota Production System (TPS) to eliminate waste, reduce variability, and improve throughput. Key aspects of JIT/lean covered include minimizing inventory, reducing setup times and lot sizes, using level scheduling and kanban signals, and emphasizing continuous improvement.