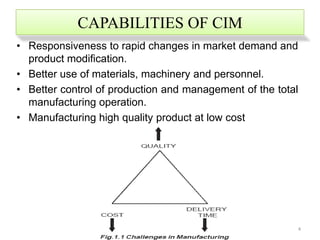

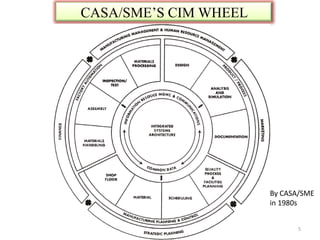

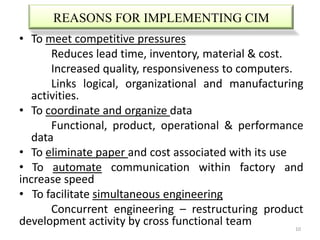

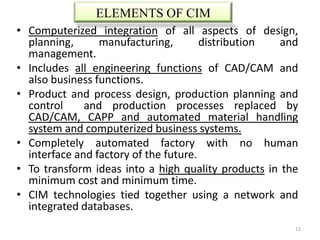

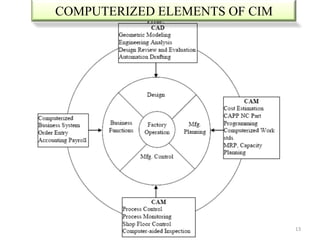

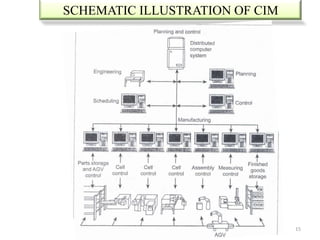

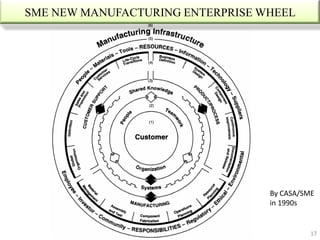

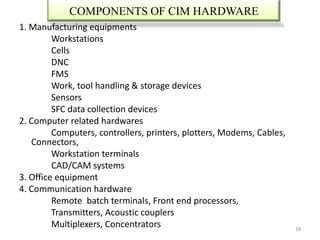

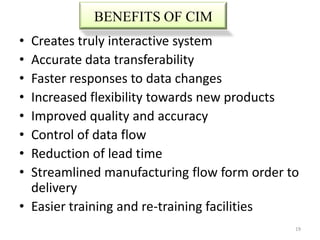

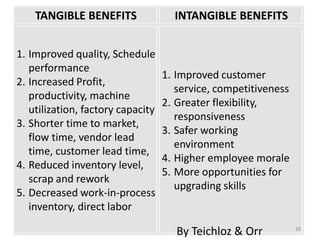

This document discusses the components of computer integrated manufacturing (CIM). It describes CIM as the integration of the total manufacturing enterprise through computer technologies and communication networks. The key components discussed include the CASA/SME model, computer networking, the OSI model, and the various subsystems and elements that make up CIM such as CAD/CAM, computer-aided process planning (CAPP), and manufacturing resource planning (MRP). The benefits of CIM implementation are also summarized such as improved quality, reduced costs and lead times, and increased flexibility and responsiveness.