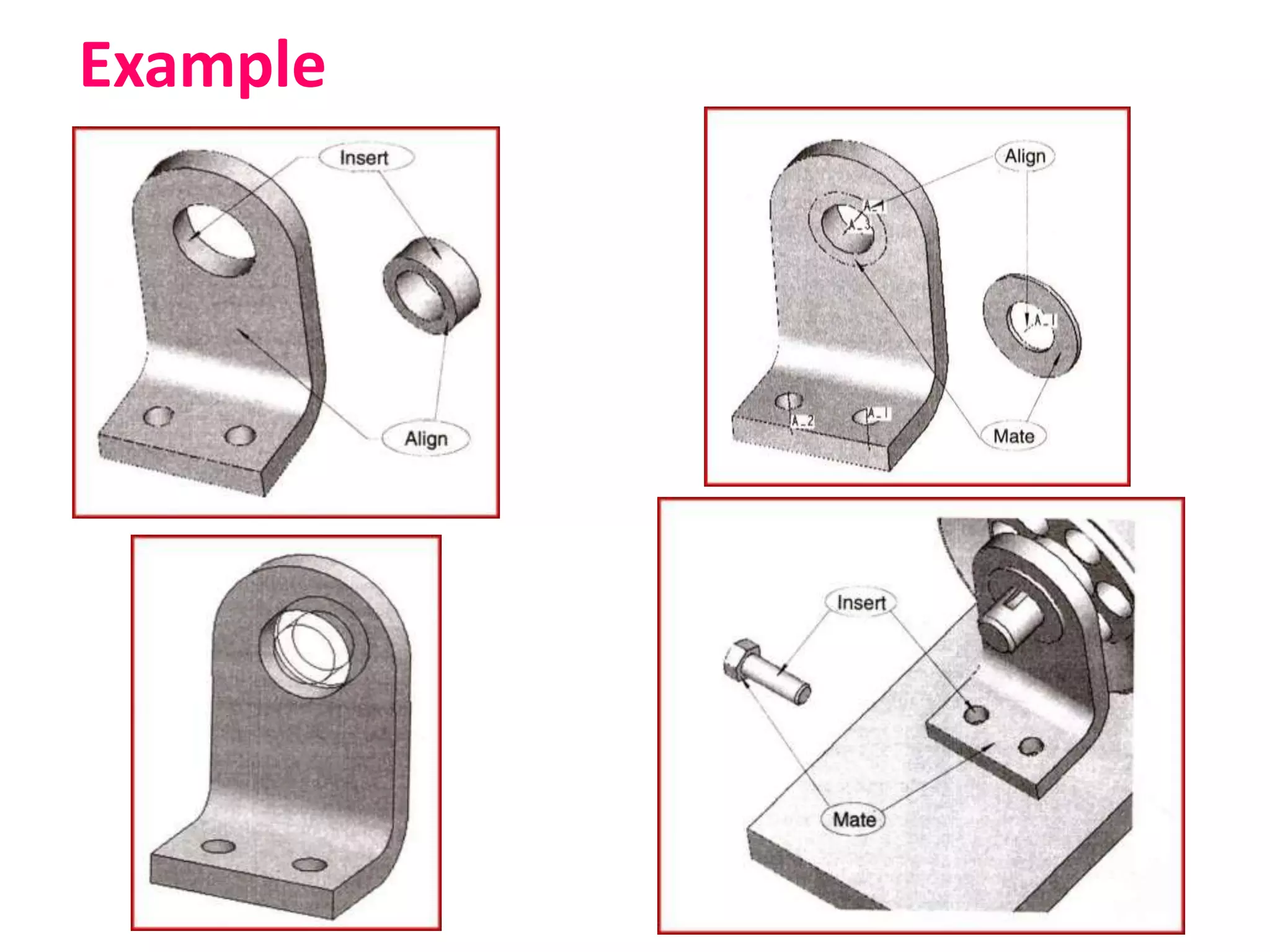

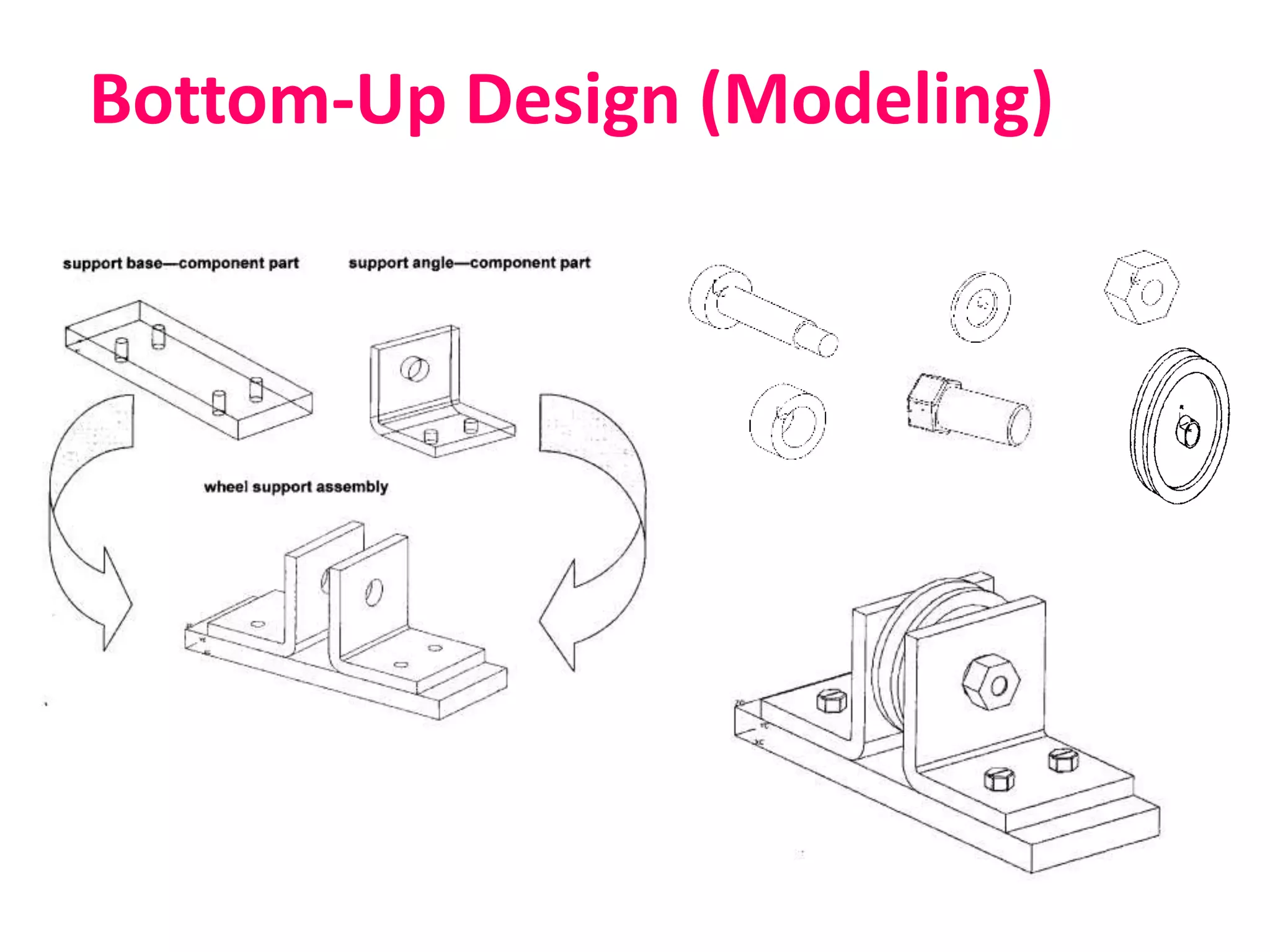

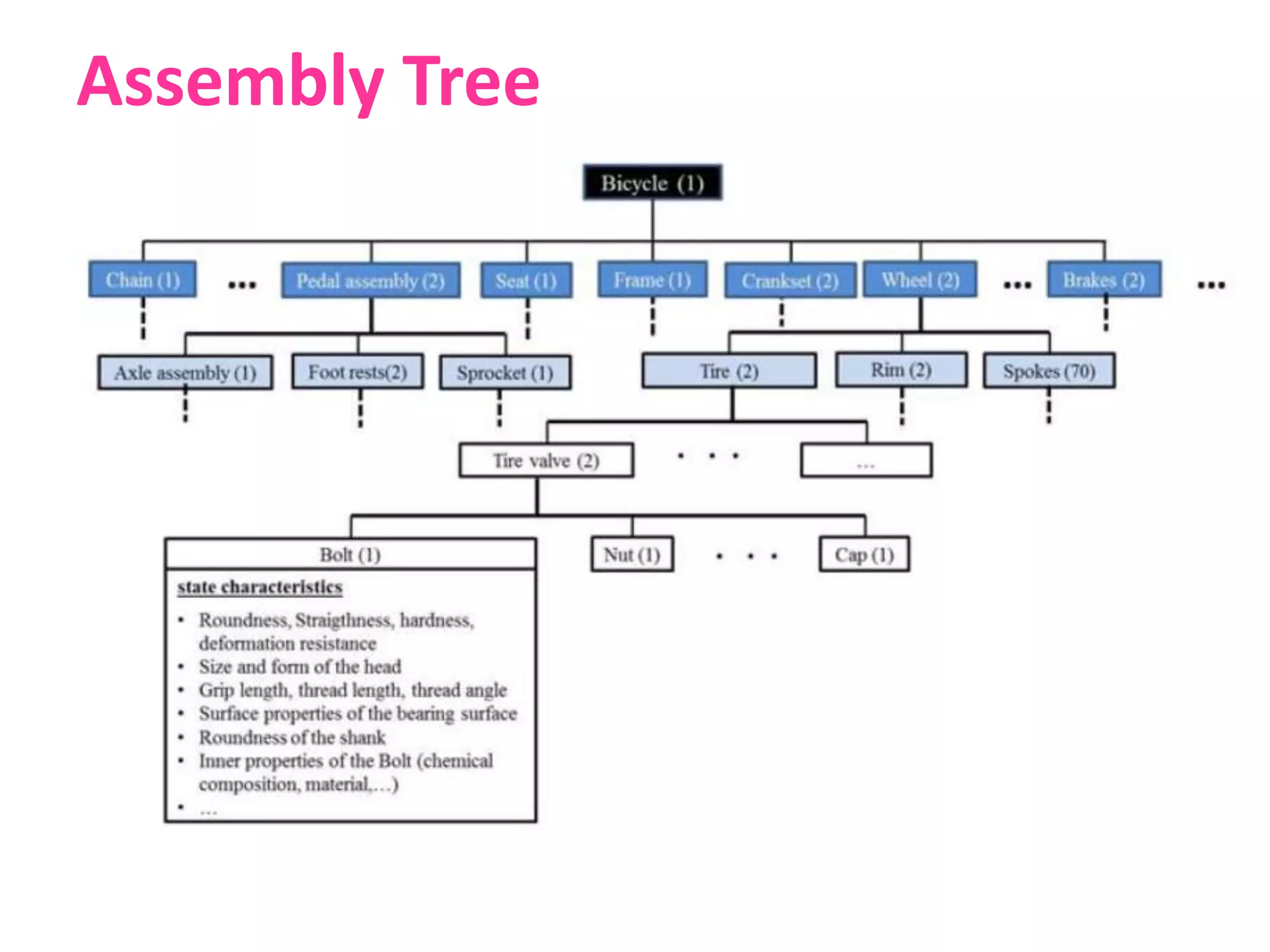

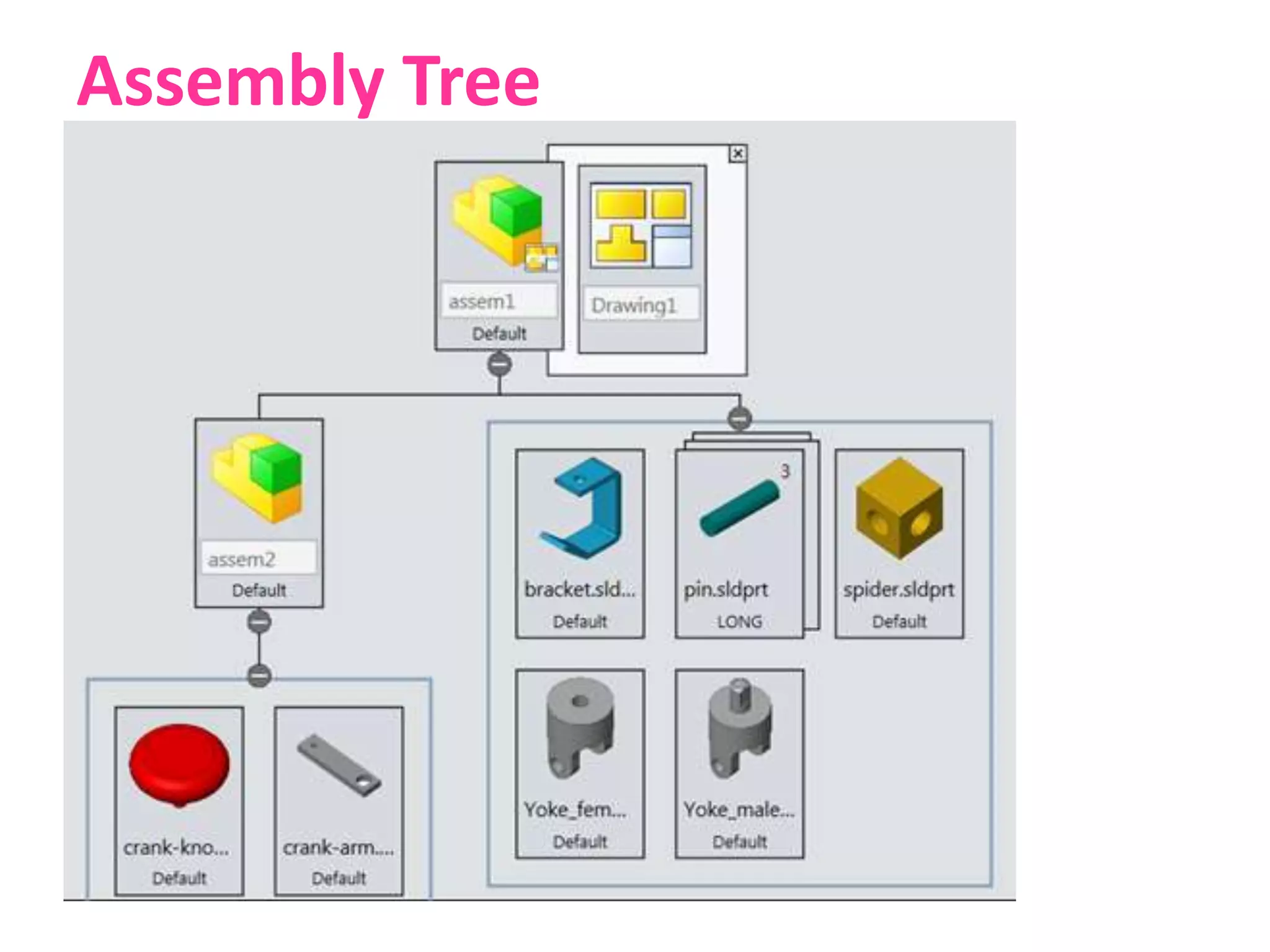

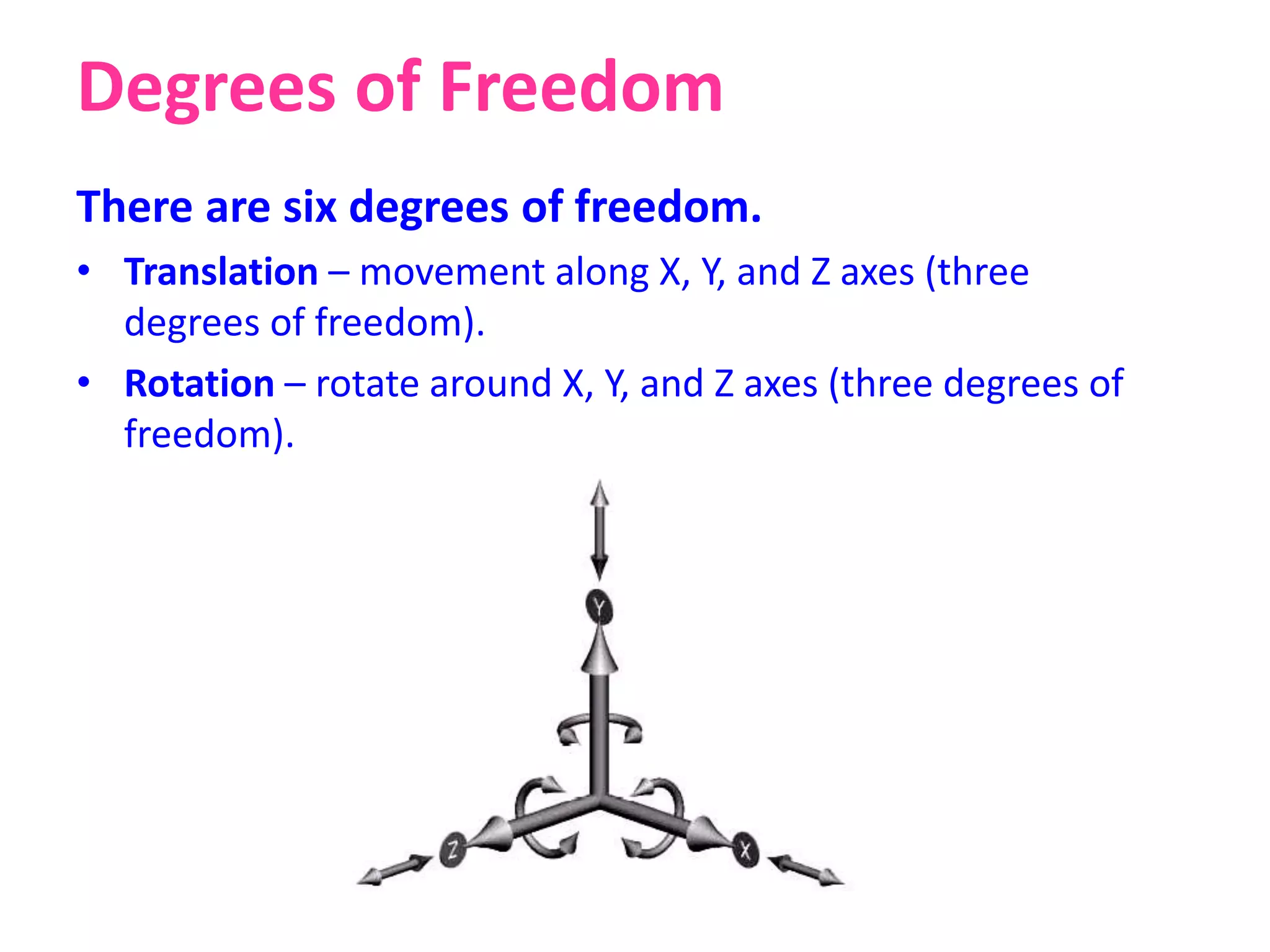

Assembly modeling allows components to be brought together to define a more complex product representation. It facilitates collaboration between different teams to ensure the assembly works together. An assembly contains component objects that can be individual parts or subassemblies. There are two main approaches to assembly modeling - bottom-up builds the assembly from individual pre-made parts, while top-down designs parts within the assembly context. Mating conditions like concentric or parallel define relationships between components.