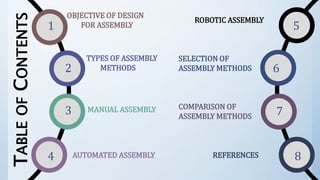

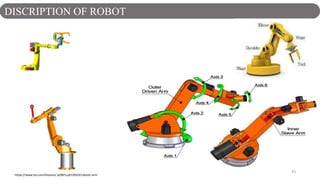

This document discusses various assembly methods including manual, automated, and robotic assembly. It provides details on the characteristics, guidelines, types, and factors for selecting each assembly method. Manual assembly relies on human workers and is flexible but has a constant cost. Automated assembly uses machines and is best for high volumes but requires more capital. Robotic assembly falls between manual and automated in terms of volume and capital needs. The document provides pros and cons and considerations for each assembly method.

![3

“The aim of DESIGN FOR ASSEMBLY

(DFA) is to simplify the product so

that the cost of assembly is reduced.”

[1]

Further,

It also improved quality and reliability and,

It helps in reduction in production equipment and

part inventory.

OBJECTIVES OF DESIGN FOR ASSEMBLY (DFA)](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-3-320.jpg)

![6

A Manual assembly line is a production line that consists of a sequence of workstations.

At each workstation Product are assembled by human workers as they move along the line.

At each station, a portion of the total work is performed on each unit.

The common practice is to "launch" base parts onto the beginning of the line at regular

intervals.

WHAT IS MANUAL ASSEMBLY ? [3]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-6-320.jpg)

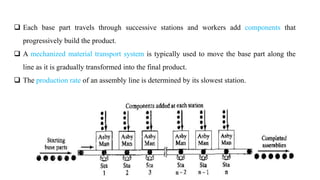

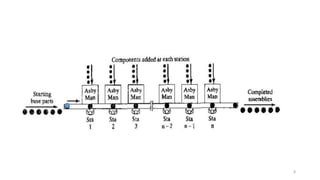

![9

In manual assembly, the operations are carried out manually with or without the aid of

simple, general purpose tools like screwdrivers and pliers.

Individual components are transferred to the workbench either manually or by employing

mechanical equipment such as parts feeds or transfer lines and then are manually

assembled.

Bins with typically un-oriented parts. Simple clamping fixtures.

This assembly method is characterized by its flexibility and adaptability.

The assembly cost per product is nearly constant.

Cost is not a function of volume. Instead, function of labour rate.

Good for low to high volume. Very low capital investment

CHARACTERISTICS OF ASSEMBLY METHODS [1]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-9-320.jpg)

![10

• Eliminate the need for workers to make decisions or adjustments

• Ensure accessibility and visibility

• Eliminate the need for assembly tools and gauges (self-locating parts)

• Minimize the number of different parts - use "standard" parts

• Minimize the number of parts

• Avoid or minimize part orientation during assembly (symmetrical parts)

• Prefer easily handled parts that do not tangle or nest within one another

Many such products are sold as "ready-to-assemble" kits or

require that assembly be shifted to cheaper labor markets.

DESIGN GUIDELINES FOR MANUAL ASSEMBLY [1]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-10-320.jpg)

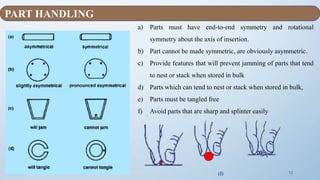

![11

• The process of manual assembly can be divided into two

separate areas:

1. Handling (acquiring, orienting, and moving the parts)

2. Insertion and Fastening (mating a part to another part

or group of parts)

GENERAL DESIGN GUIDELINES FOR MANUALASSEMBLY [1]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-11-320.jpg)

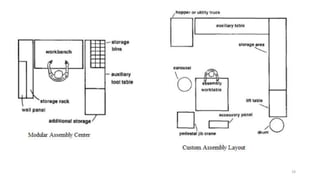

![18

1. For small parts placed within easy reach of assembly

worker, handling times given in Fig. are adequate if

employing:

bench assembly

multi-station assembly

2. For Large Part, It will not be possible to place an

adequate supply of parts within easy arm's reach of

assembly worker for volumes that:

Do not justify transfer systems

Assembly contains several parts that weigh more

than 5 lb or are over 12” in size.

Largest part is less than 35” in size

No part weighs more than 30 lb

In this case, modular assembly center might be used.

TYPES OF MANUALASSEMBLY METHODS [2]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-18-320.jpg)

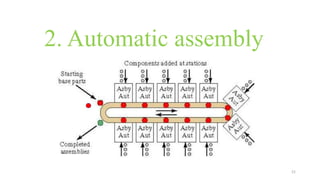

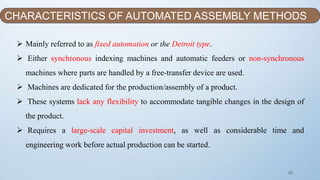

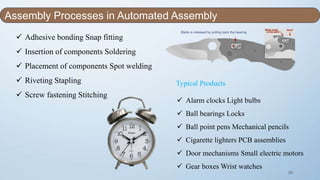

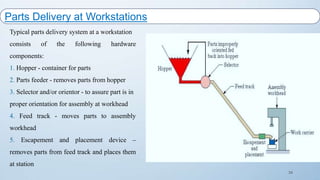

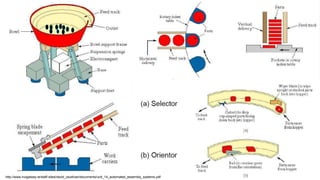

![22

Fixed automation usually:- Most automated

assembly systems are designed to perform a fixed

sequence of assembly steps on a specific product that is

produced in very large quantities.

Where is automated assembly appropriate:

High product demand

Stable product design

The assembly consists of no more than a limited

number of components

The product is designed for automated assembly

AUTOMATED ASSEMBLY[2]

“The use of mechanized and

automated devices to

perform the various

assembly tasks in an

assembly line or cell”](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-22-320.jpg)

![24

Use self-aligning and self-locating features.

Avoid screws/bolts.

Use the largest and most rigid part as the assembly base and fixture.

Perform assembly in a layered, bottom-up manner.

Use standard components and materials.

Avoid tangling or nesting parts.

Avoid flexible and fragile parts.

Avoid parts that require orientation.

Use parts that can be fed automatically.

Design parts with a low center of gravity.

AUTOMATED ASSEMBLY GUIDELINES (HARD AUTOMATION ) [1][3]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-24-320.jpg)

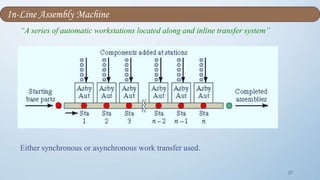

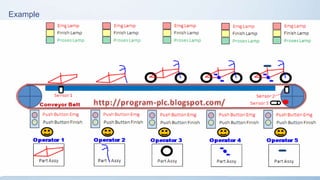

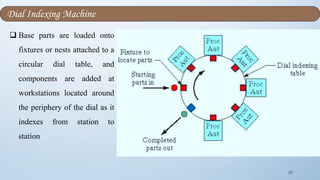

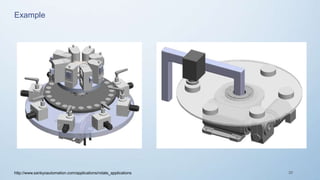

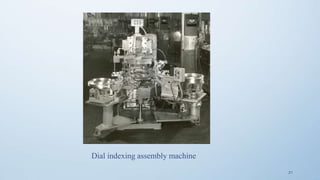

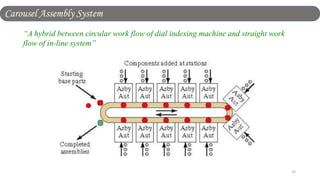

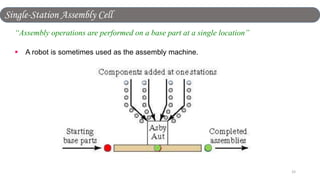

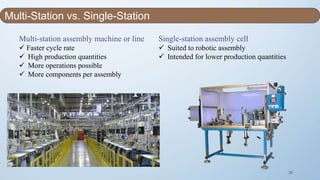

![26

Based on physical configuration:

1. In-line assembly machine

2. Dial indexing machine

3. Carousel assembly system

4. Single-station assembly cell

TYPES OF AUTOMATED ASSEMBLY SYSTEMS[3]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-26-320.jpg)

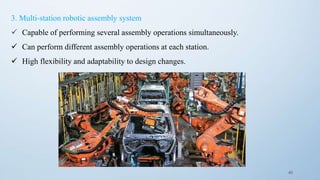

![38

Production volume is higher than that of a manual assembly

system but lower than that of an automatic assembly system

(Fixed automation).

Common forms of Robotic Assembly:

1. One-arm robot operating at a single

workstation that includes parts feeders,

magazines, etc.

CHARACTERISTICS OF ASSEMBLY METHODS [3]

new.math.uiuc.edu](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-38-320.jpg)

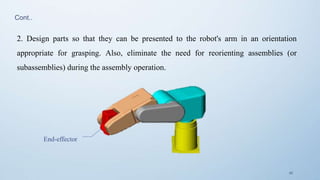

![41

The product design rules for robotic assembly are basically the same as those for manual and/or automatic

assembly.

Two very important and crucial considerations

that have to be taken into account when

designing components for robotic assembly:

1. Design a component so that it can be grasped,

oriented, and inserted by that robot's end

effector. Failure to do so will result in the need

for an additional robot and, consequently,

higher assembly cost.

DESIGN FOR ROBOTIC ASSEMBLY [3]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-41-320.jpg)

![44

Factors affecting selection of an assembly method:

Cost of assembly

Annual production volume (or production

rate)

Number of individual components to be

assembled in a product

Number of different versions of a product / s

Availability of labour (with cost

consideration)

Payback period

SELECTION OF ASSEMBLY METHOD [1][4]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-44-320.jpg)

![45

1. Manual assembly requires the least capital

investment followed by the two simplest forms

of robotic assembly.

2. Multi-station robotic assembly system

compares to Automatic system with special-

purpose machines requires more capital

investment for a large production volume but

less capital investment for a moderate

production volume.

3. Assembly cost per product is constant for

manual assembly

Comparison of Assembly Methods [1][4]](https://image.slidesharecdn.com/designforassembly-170314015505/85/Design-for-assembly-methods-45-320.jpg)