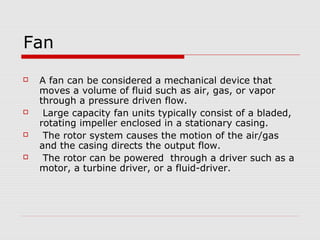

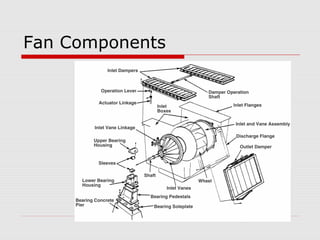

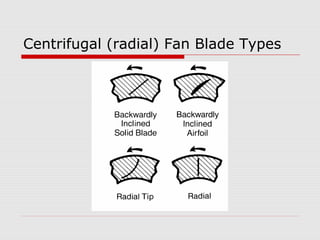

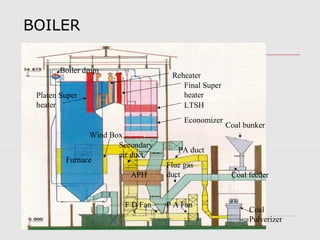

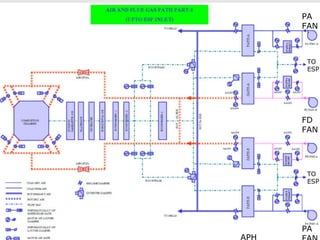

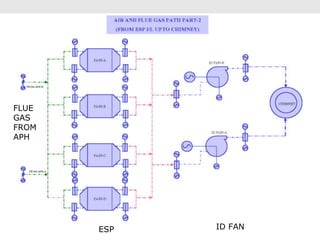

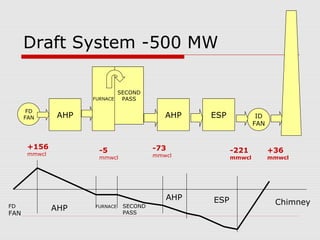

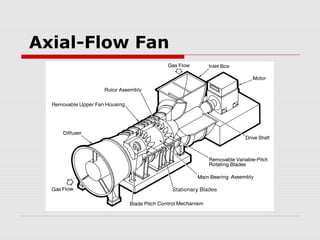

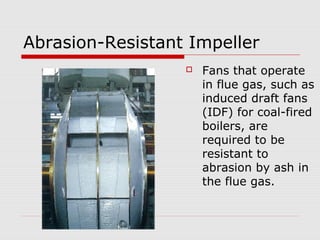

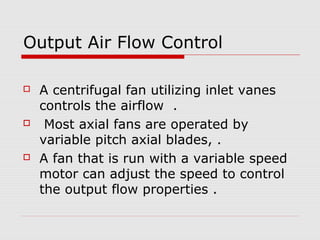

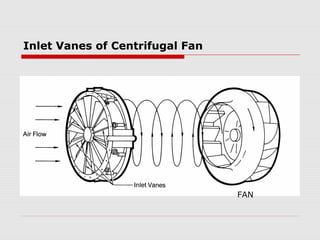

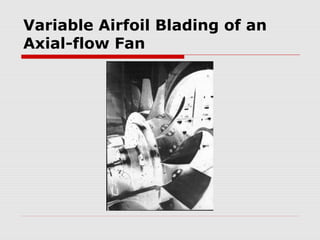

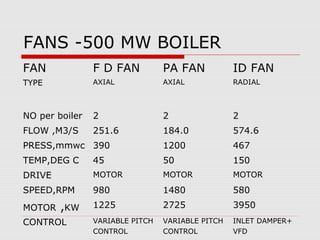

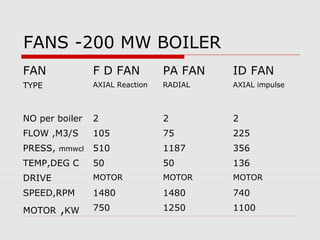

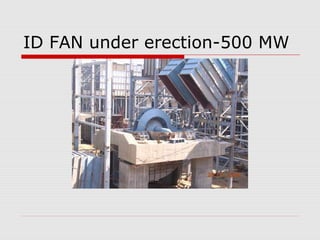

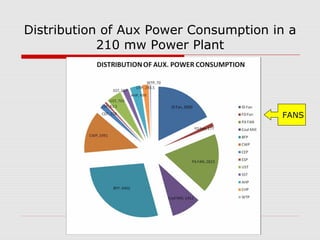

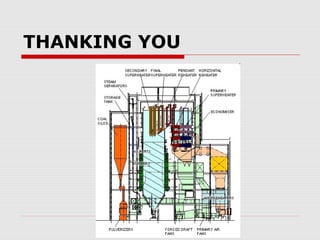

This document discusses fans used in thermal power plants. It describes the main types of fans used - forced draft fans, induced draft fans, primary air fans, and gas recirculation fans. It explains their purposes and characteristics. The key points are: forced draft fans supply air for combustion, induced draft fans exhaust flue gas, primary air fans supply air to coal pulverizers, and gas recirculation fans control steam temperature. Common damage mechanisms for power plant fans are erosion, corrosion, and vibration. Condition monitoring is important to predict failures.