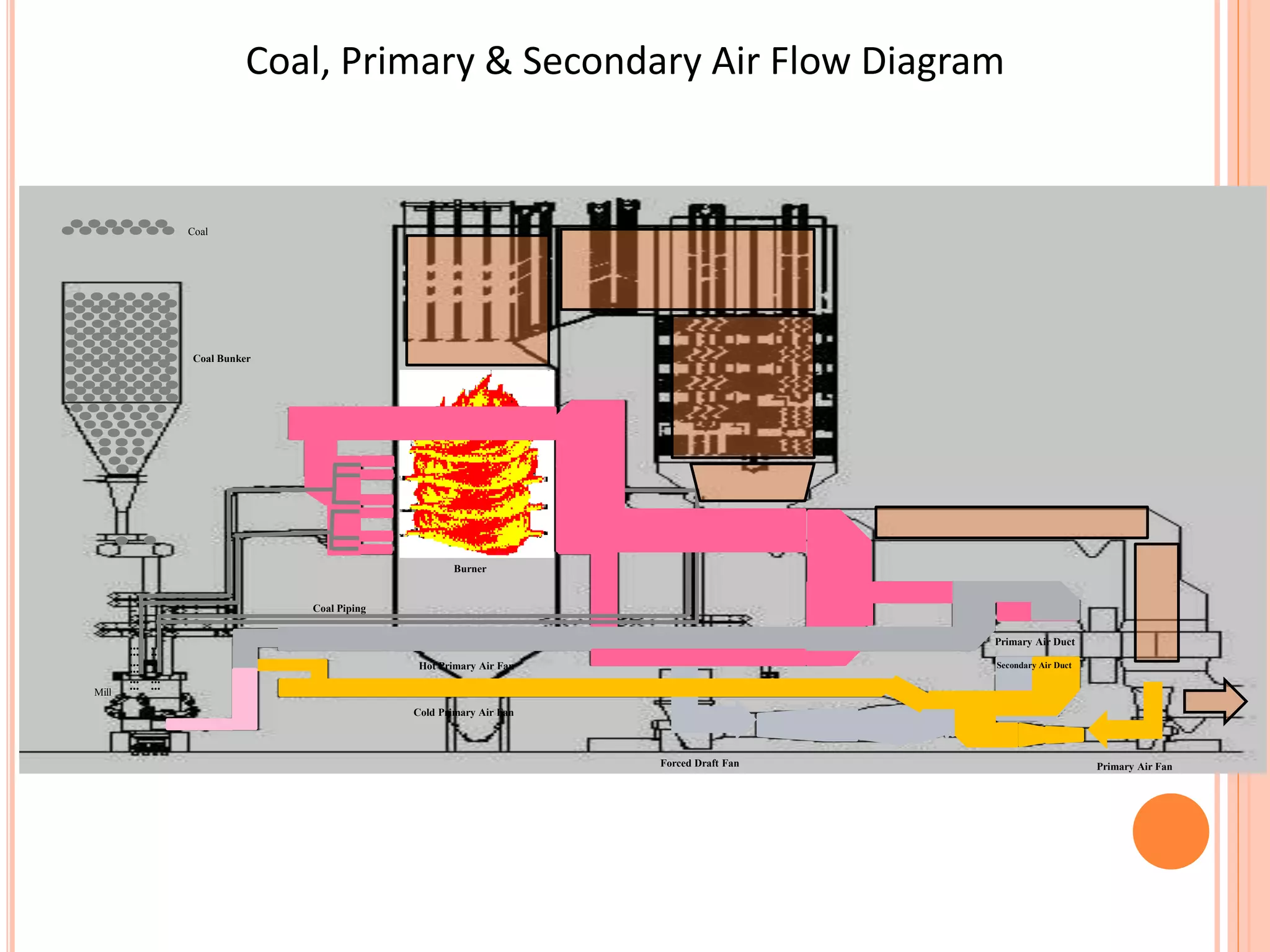

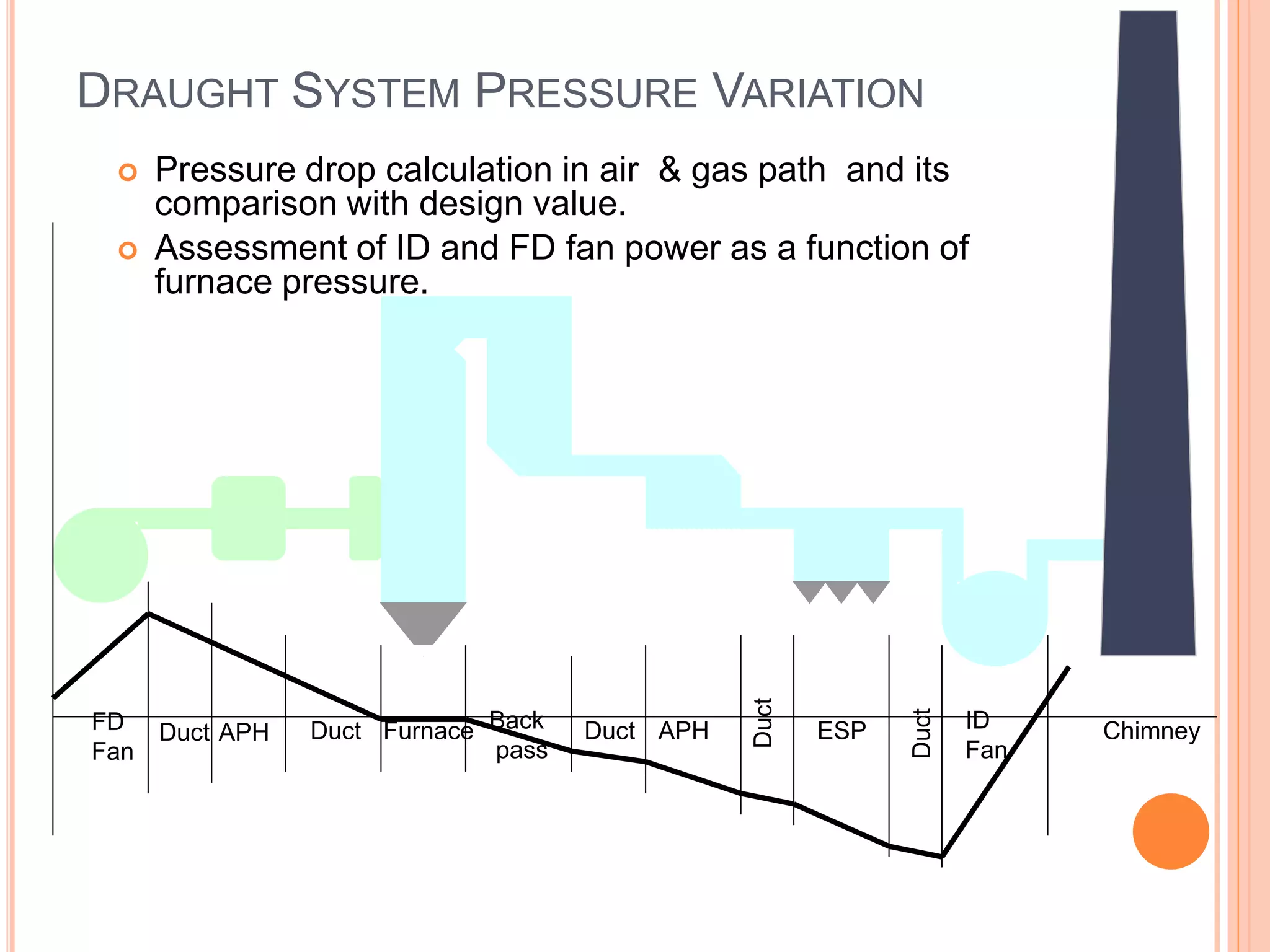

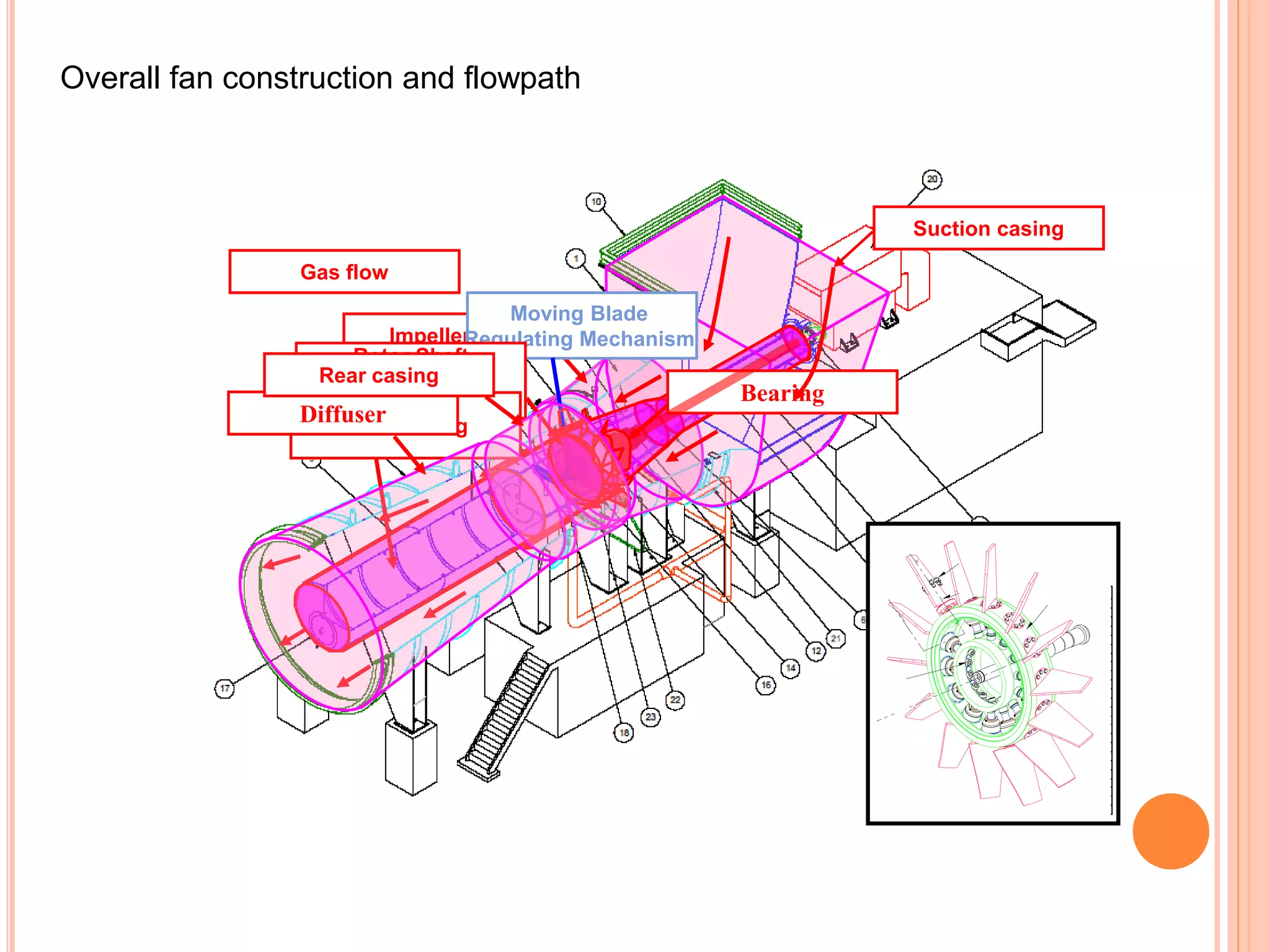

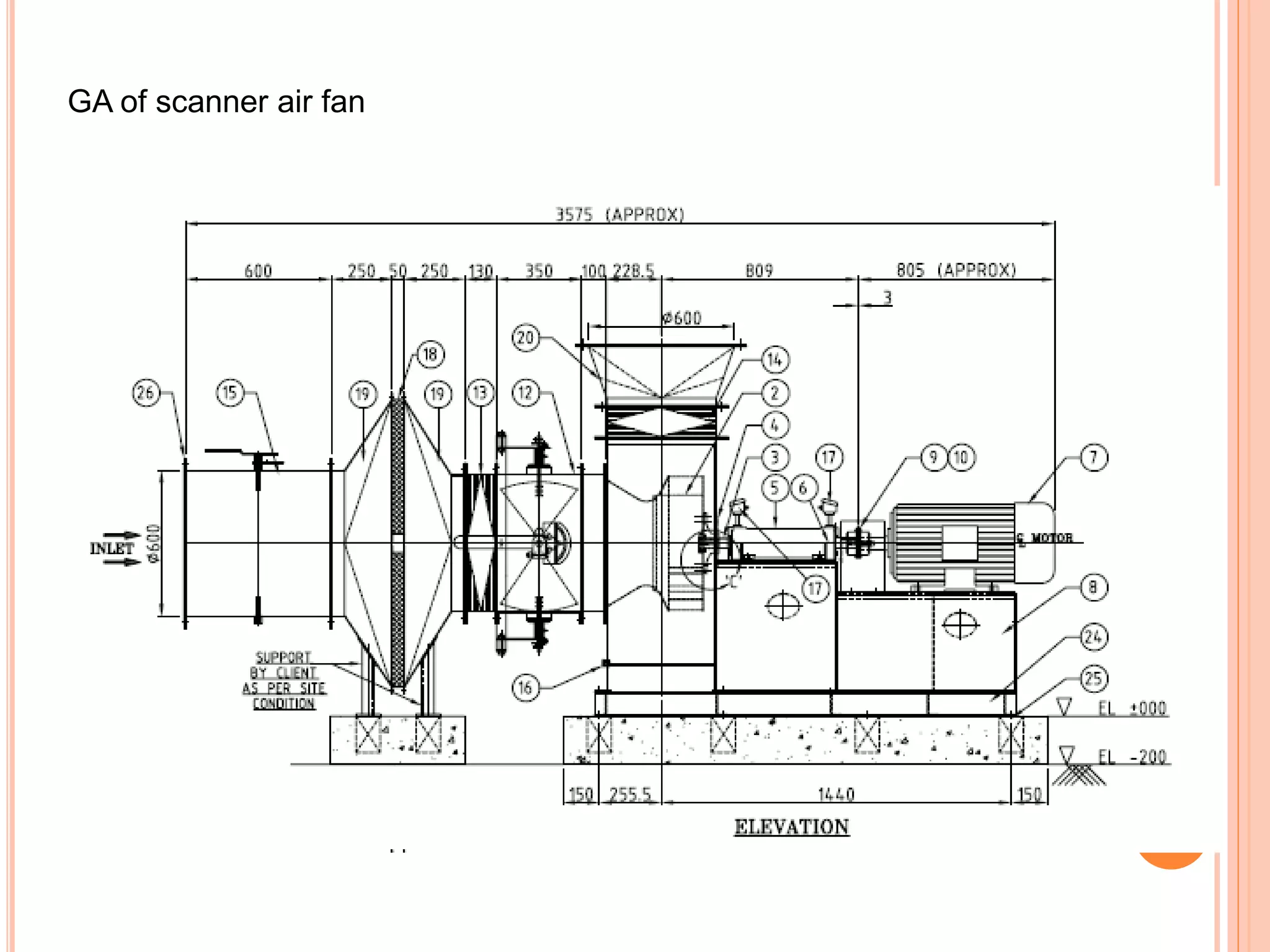

This document provides an overview of the air and gas system for a boiler. It describes the major components needed to supply combustion air and remove flue gases, including forced draft fans, induced draft fans, air heaters, ducting and dampers. It explains the flow of air from the coal bunker and mills through primary and secondary air ducts and fans into the furnace. The draught system and pressure variations are also covered.