The document provides details of a cooling tower renovation project at a fertilizer plant. Key points:

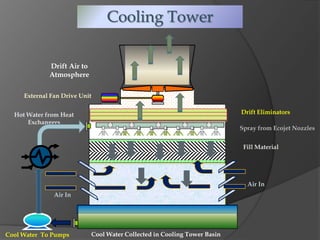

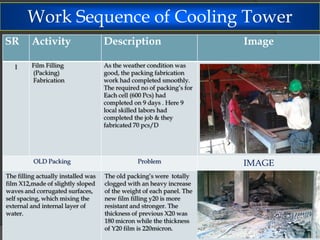

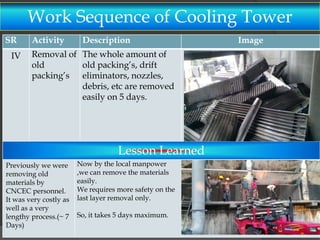

- The existing cooling tower packing, drift eliminators, and nozzles needed replacement as their working life had expired after 7-10 years.

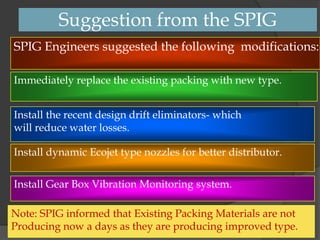

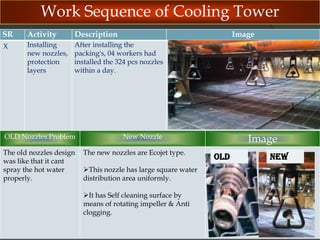

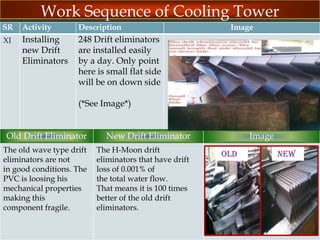

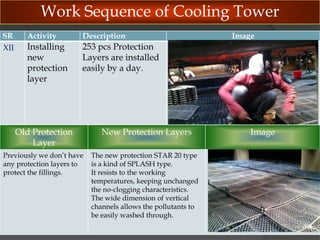

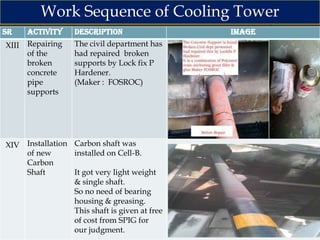

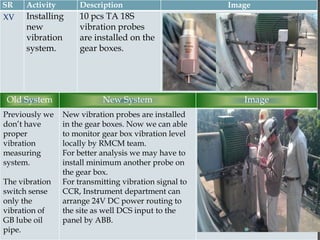

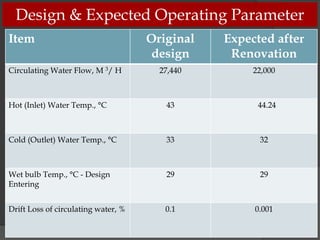

- Modifications included installing new packing, drift eliminators, dynamic Ecojet nozzles, and a vibration monitoring system.

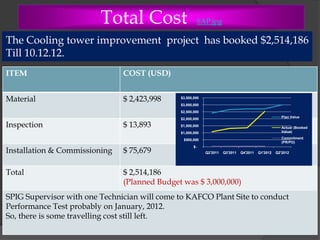

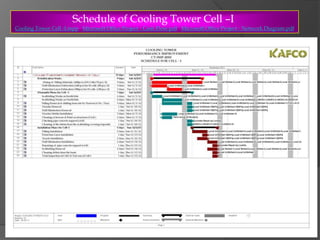

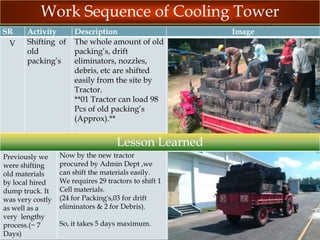

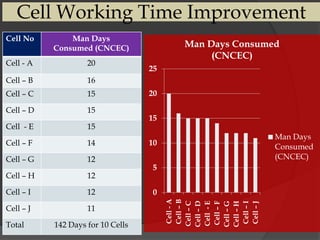

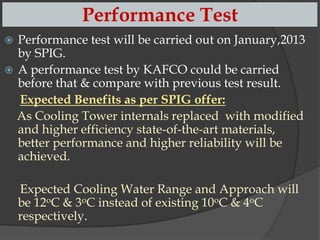

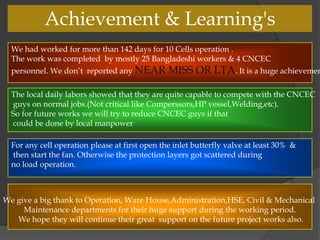

- The project was completed on time and under budget using mostly local labor. It is expected to improve cooling tower performance and reliability.

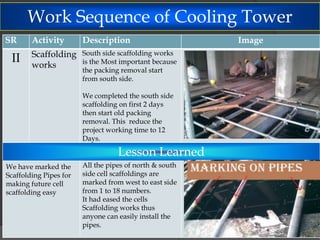

- Lessons learned include using local labor for most tasks and marking scaffolding pipes to streamline future work. The renovation reduced circulating water temperature ranges and approach.