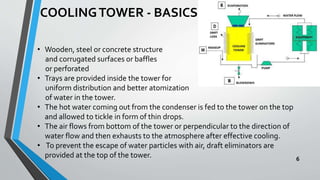

The document discusses cooling towers, their system design, classification, operation, and performance assessment. It highlights key factors such as temperature ranges, water evaporation, and structural stability challenges faced in high wind conditions. Conclusively, it emphasizes the need for effective heat transfer and operational efficiency despite inherent losses in the cooling process.