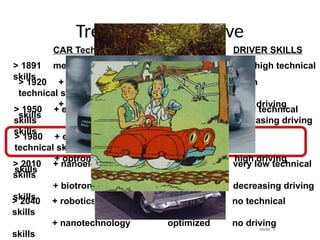

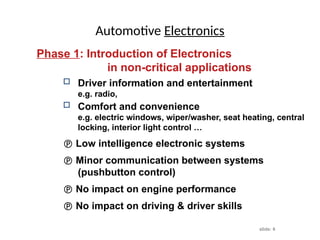

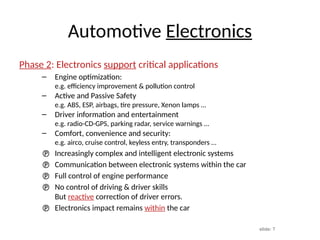

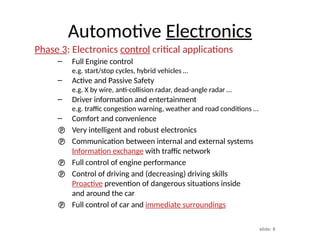

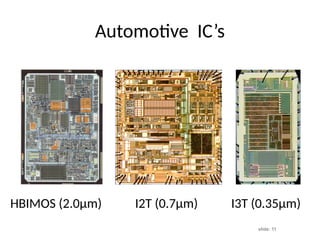

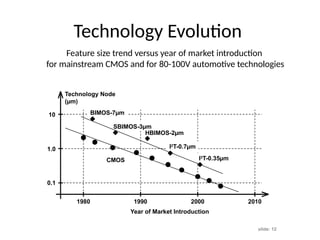

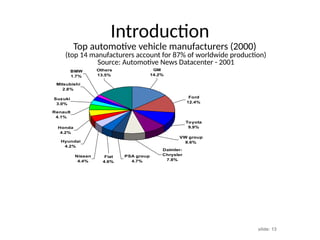

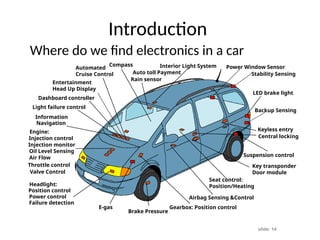

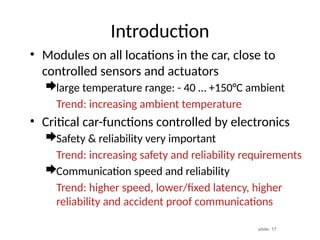

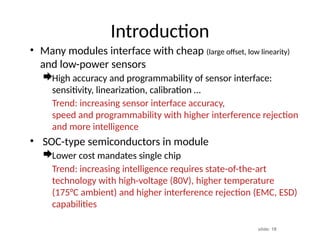

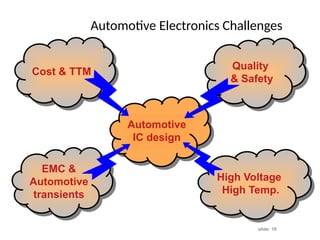

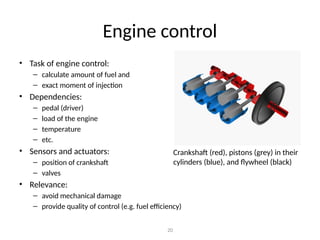

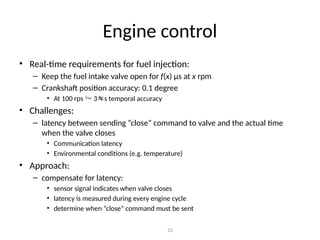

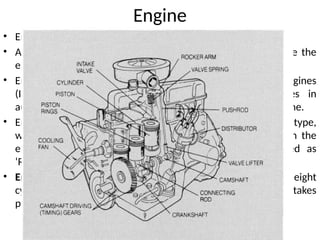

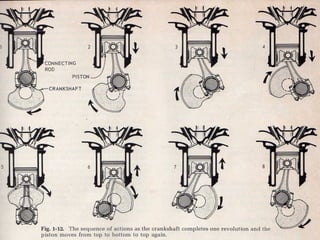

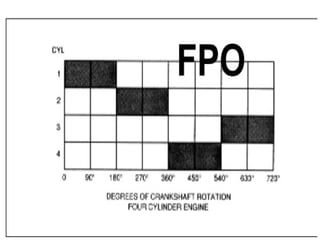

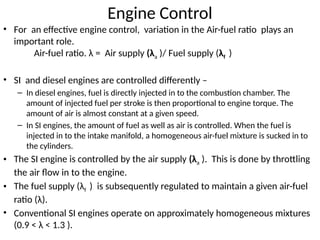

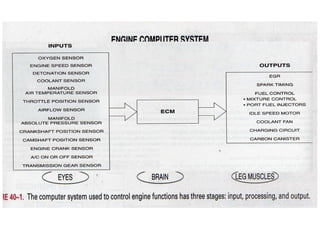

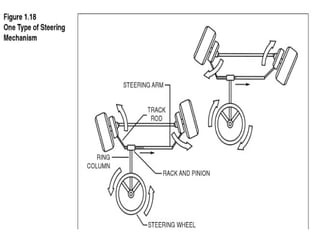

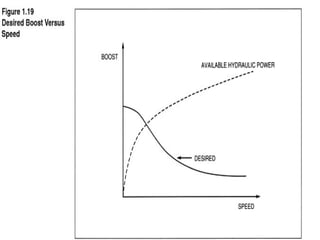

The document outlines a course on automotive electronics, detailing desired outcomes such as understanding automotive systems, sensors, and control mechanisms. It covers various units on engine fundamentals, sensors, actuators, and communication systems, along with applications like vehicle motion control and diagnostics. Additionally, it highlights the evolution of automotive electronics, crucial components, and engineering challenges associated with modern vehicles.